Low-temperature stop valve

A cut-off valve and low-temperature technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of increasing the length of valve stems and brackets, increasing manufacturing costs, etc., and achieve the effects of realizing sealing functions, shortening lengths, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

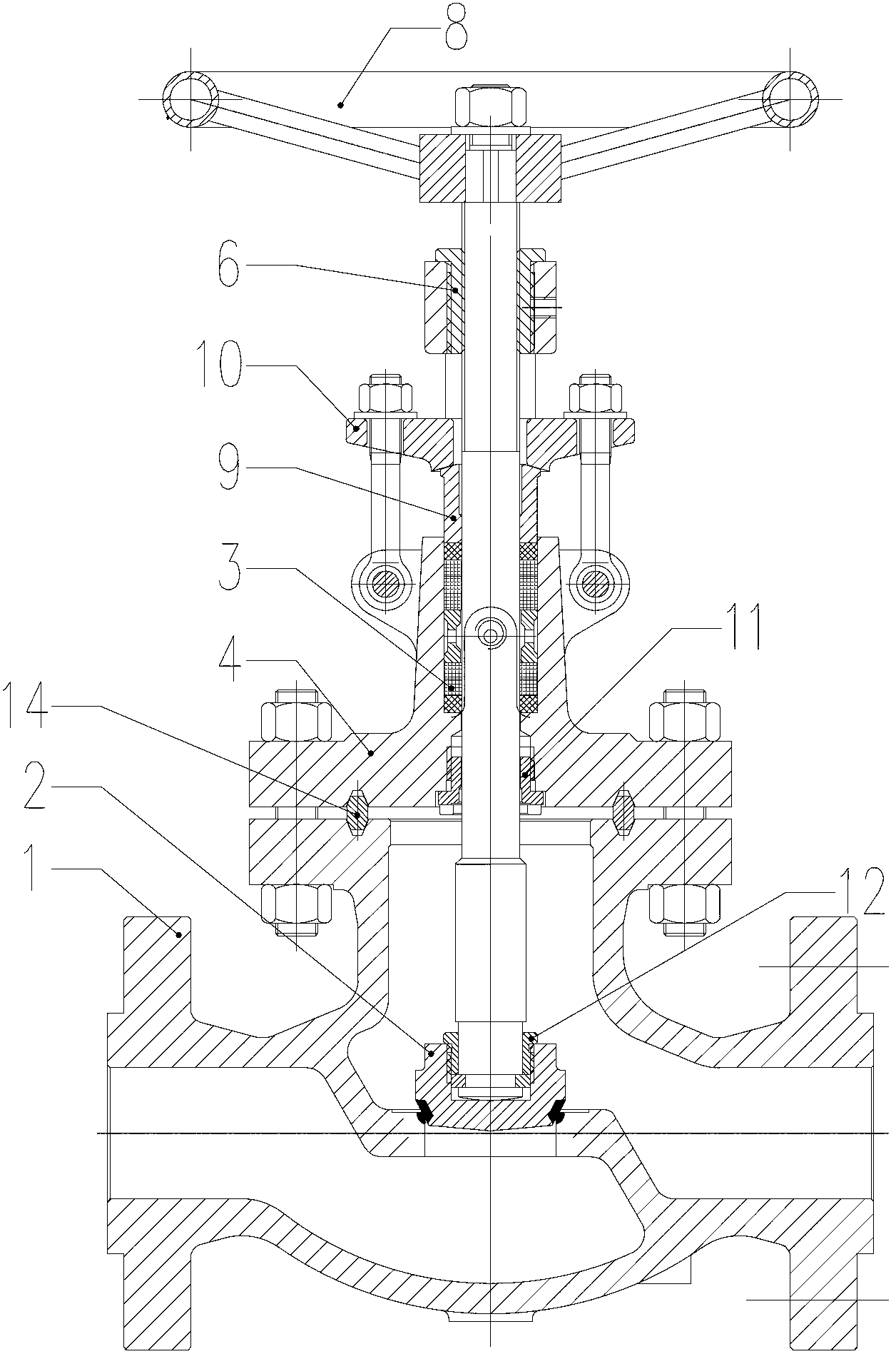

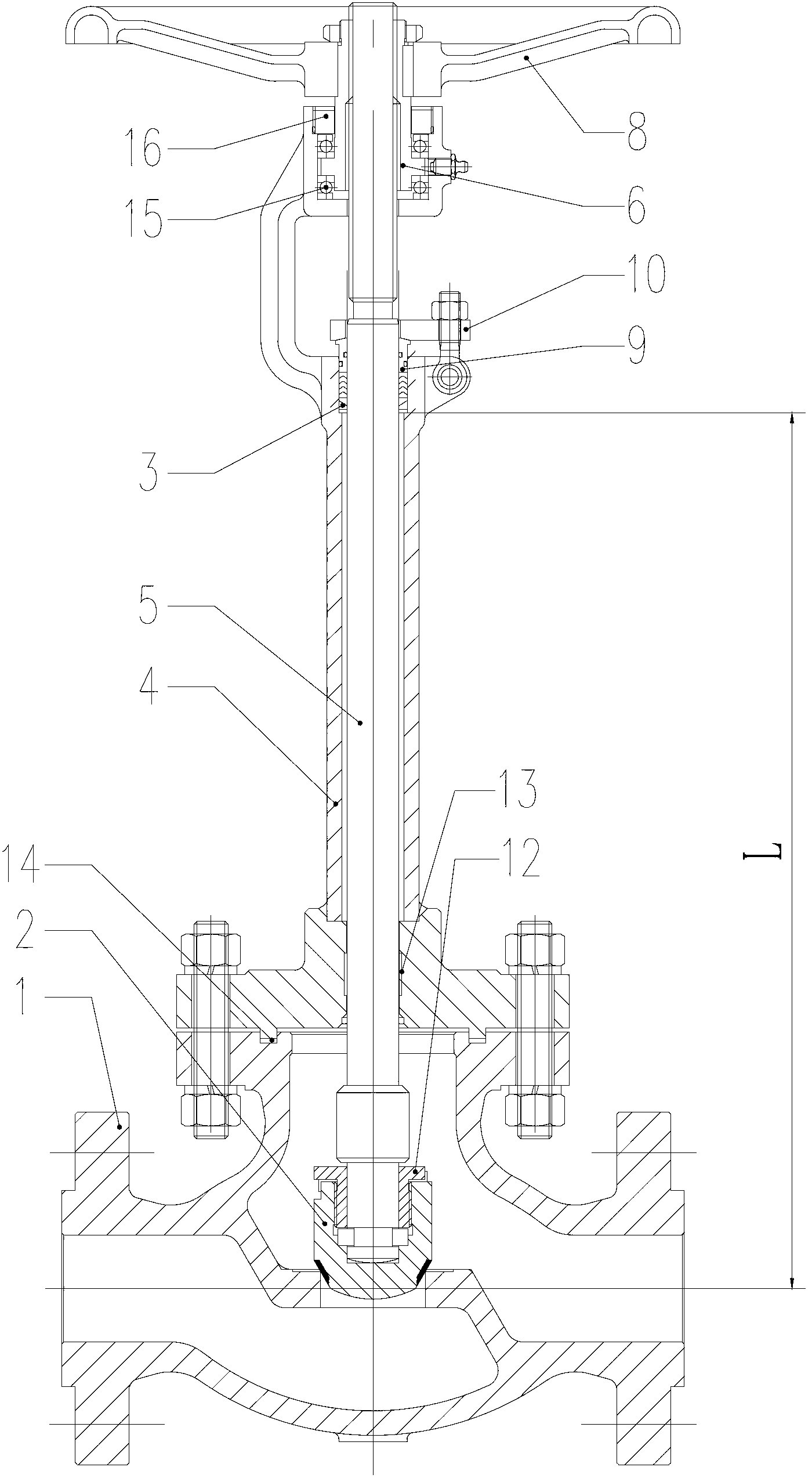

[0016] Such as figure 1 As shown in the figure, for ordinary globe valves, the stem nut is installed on the bracket connected to the bonnet. If this structure is used to design low temperature globe valves, such as figure 2 As shown, since the extension length L of the cold box must be guaranteed, the valve stem is already very long, and the structure of fixing the valve stem nut by the bracket is not economical enough.

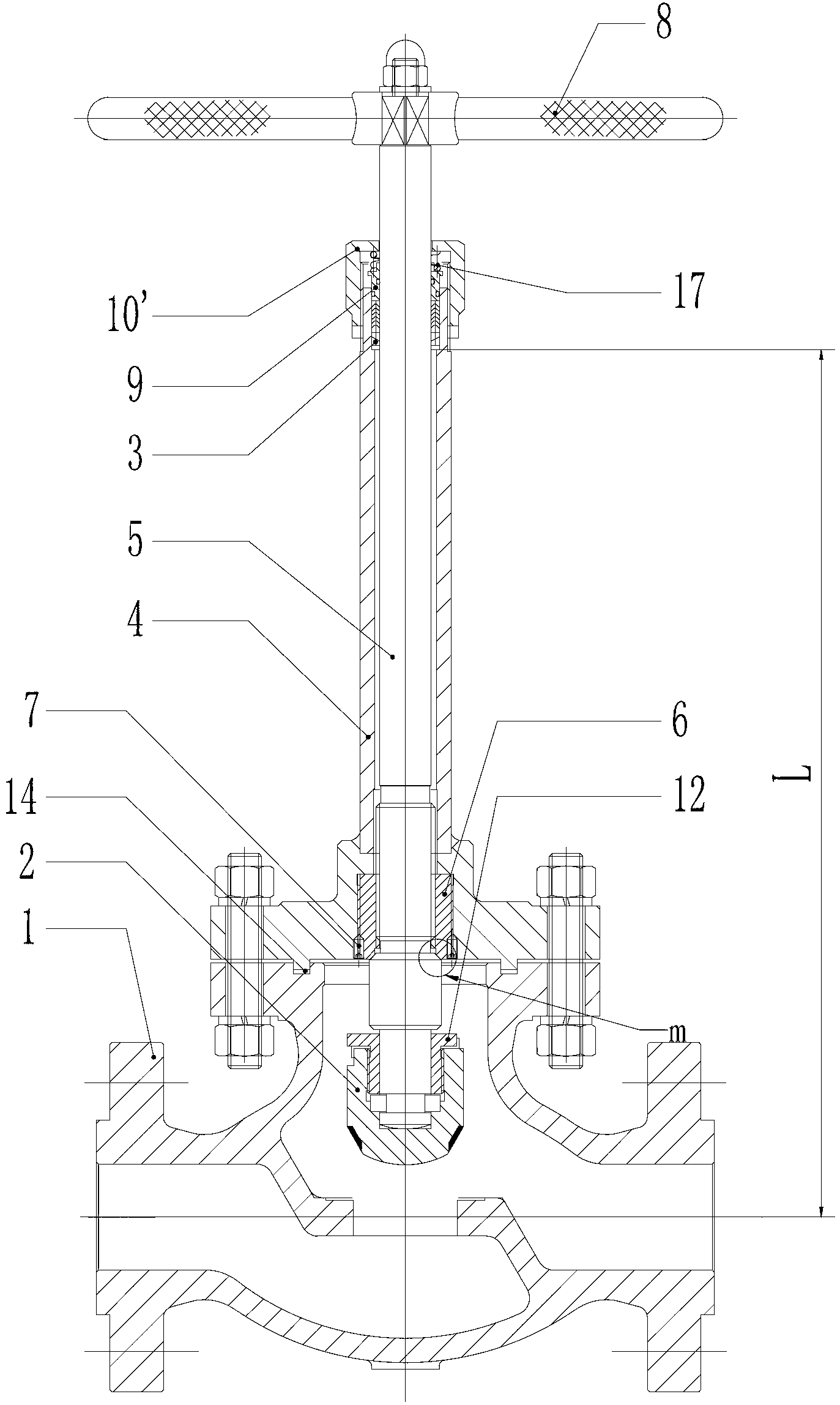

[0017] Such as image 3 , Figure 4 As shown, the cryogenic globe valve of the present invention includes a valve body 1, a valve cover 4, a valve core 2 and a valve stem 5 connected to the valve core 2, the valve body 1 is flanged to the valve cover 4, and the valve stem 5 is connected to the valve cover 4 There is a stuffing box 3 between them, and the packing filled in the stuffing box 3 is pressed and fixed by the packing gland 9 and the packi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com