Load calculation method for paired tapered roller bearings

A tapered roller bearing, load calculation technology, applied in the direction of measuring devices, instruments, measuring force, etc., can solve the problem of inaccurate precision, achieve the effect of optimizing the mechanical system, prolonging the life of the bearing, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

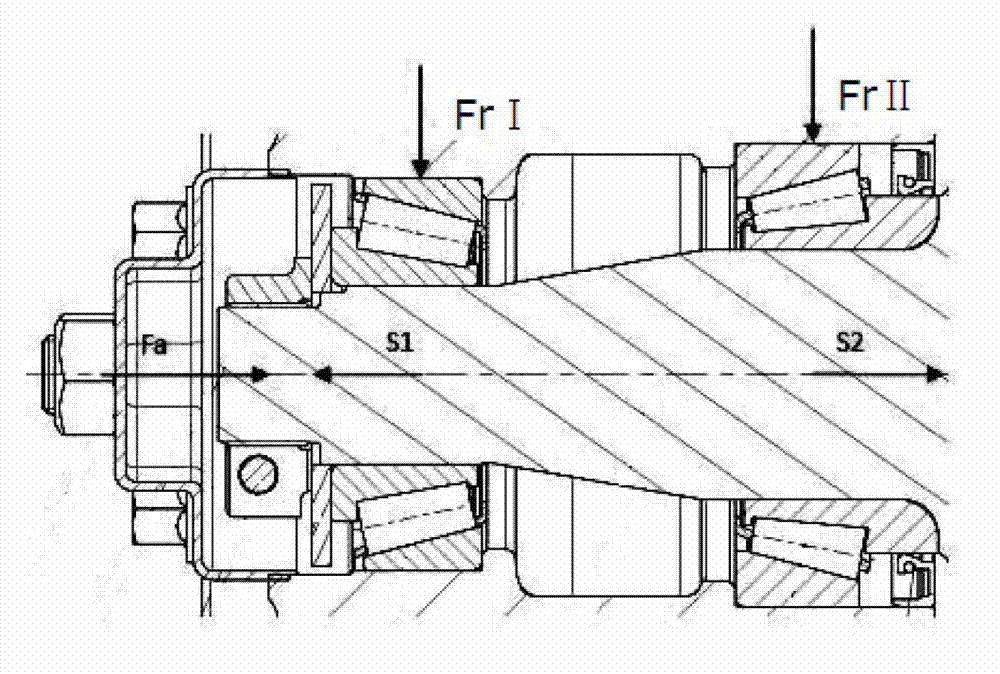

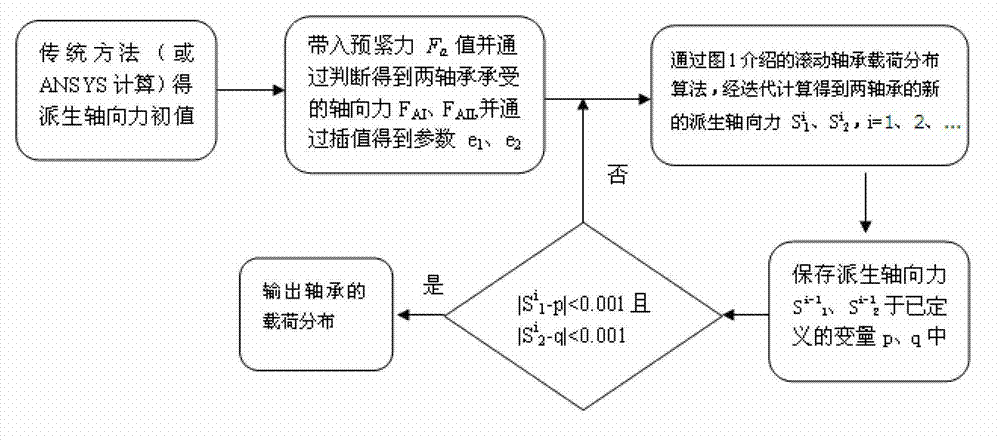

[0020] Such as figure 1 As shown, tapered roller bearings will generate derived axial forces when bearing radial loads, and the influence of axial derived forces must be considered in the analysis. Bearings I and II bear radial load F respectively rI , F rII , and bear the axial load F a . The traditional calculation method of the axial derived force under the action of radial force is: respectively set the derived axial force of the two bearings as S 1 , S 2 , the axial load borne by bearings I and II can be obtained by the following formula:

[0021] f a +S 2 ≥S 1 when F aI =F a +S 2 , F aII =S 2

[0022] f a +S 2 1 when F aI =S 1 , F aII =S 1 -F a

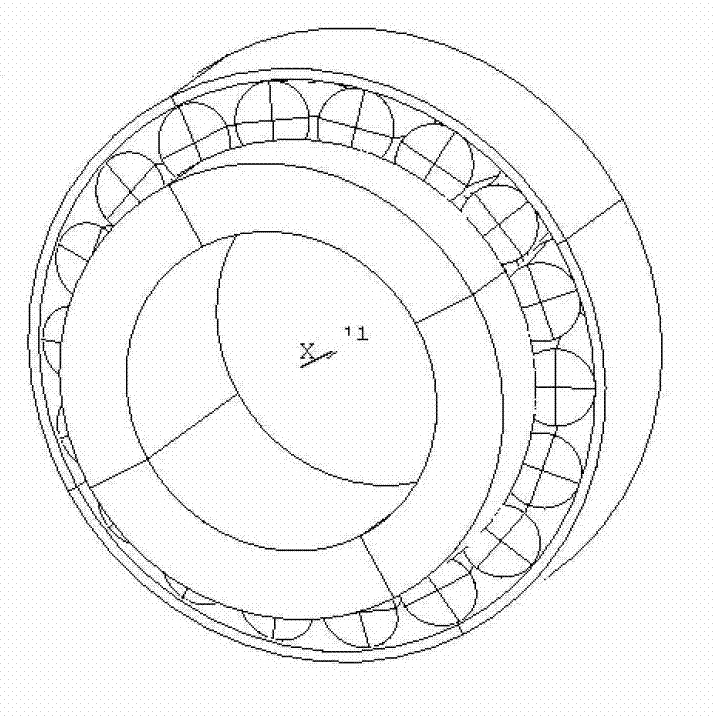

[0023] On the premise that the axial force and radial force on the bearing are known, the load distribution of the bearing can be obtained by the following methods:

[0024] via calculations And look up the table to get ε and J r (ε) value, where α is the contact angle of the bearing outer ring, F r is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com