Anti-bending test device

A testing device and bending resistance technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of time-consuming, labor-intensive, low production efficiency, etc., to improve production efficiency, ensure bending resistance, save labor and the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

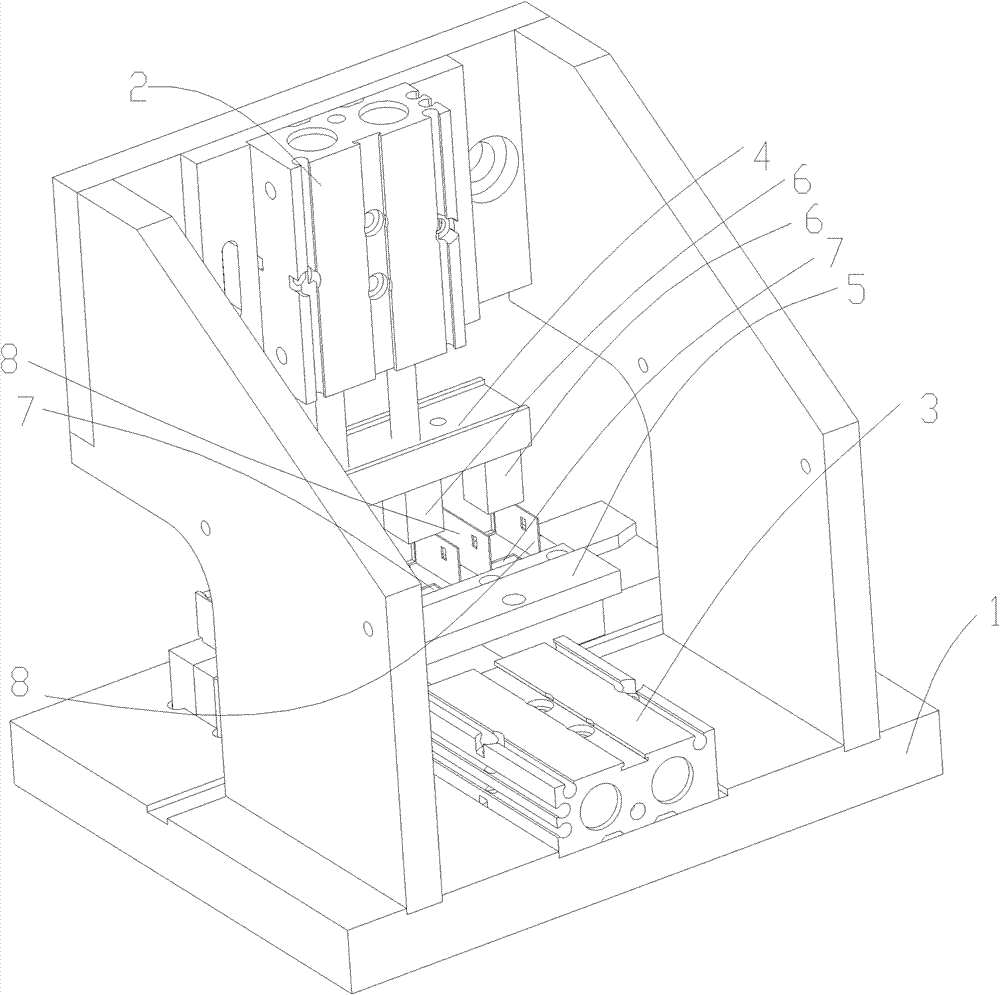

[0009] exist figure 1 Among them, the bending resistance test device includes a support base 1, a first cylinder 2, and a second cylinder 3. The cylinder bodies of the first cylinder 2 and the second cylinder 3 are fixed on the support base 1, and the support base 1 includes a horizontal part , the two side parts vertically arranged on both sides of the horizontal part, the vertical part arranged between the two side parts and above the horizontal part, the cylinder body of the first cylinder 2 is fixedly arranged on the vertical part, the first cylinder 2 The telescopic rod extends vertically, and the telescopic rod of the first cylinder 2 is set downward, the cylinder body of the second cylinder 3 is fixedly arranged on the horizontal part, and the telescopic rod of the second cylinder 3 extends along the horizontal direction, and the first cylinder 2 The first conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap