Quick splicing device for display screen

A technology of rapid splicing and display screen, applied in the direction of identification devices, connecting components, instruments, etc., can solve the problem that the display screen cannot be easily and accurately spliced with curved screens, etc., to achieve the effect of precise assembly and locking, preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The purpose of the present invention is to provide a display screen quick splicing device that can easily and quickly assemble curved display screens without any tools, and can achieve high-precision splicing effects. It is suitable for the assembly of high-density pixel display screens that require frequent disassembly.

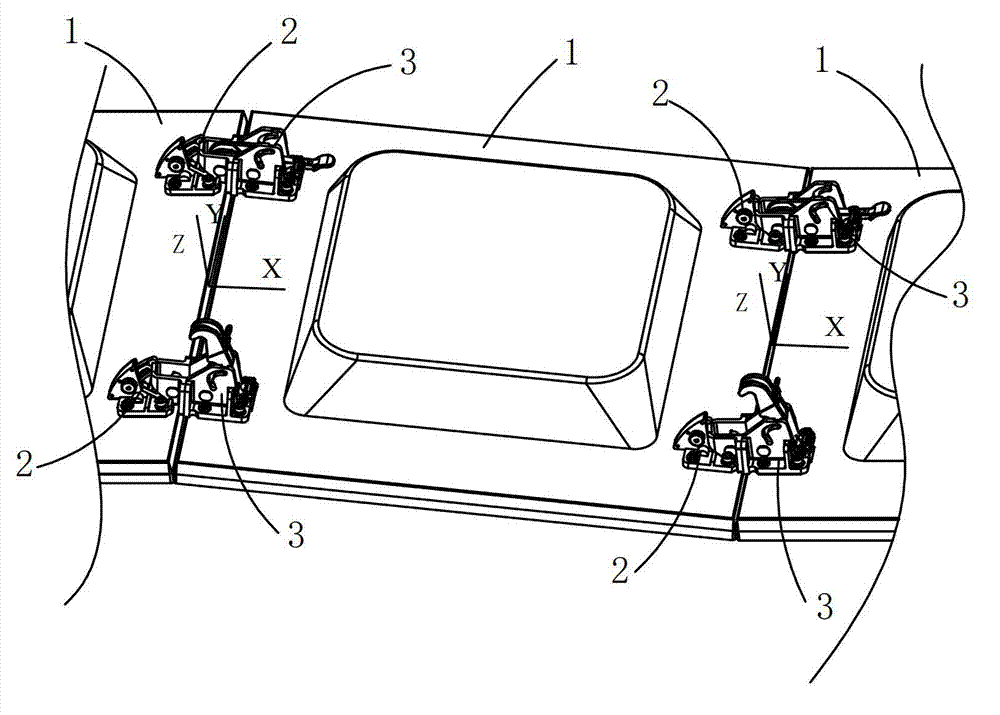

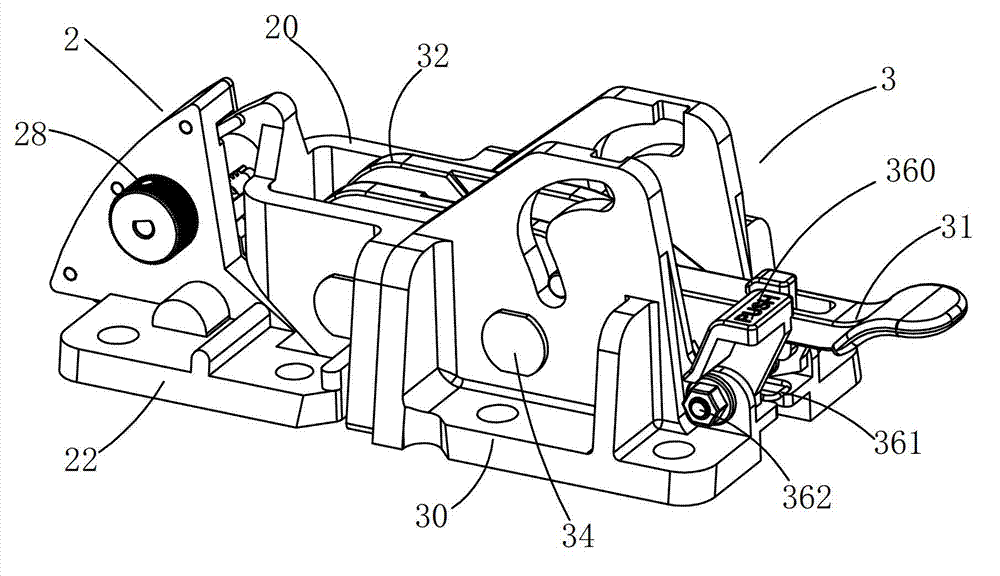

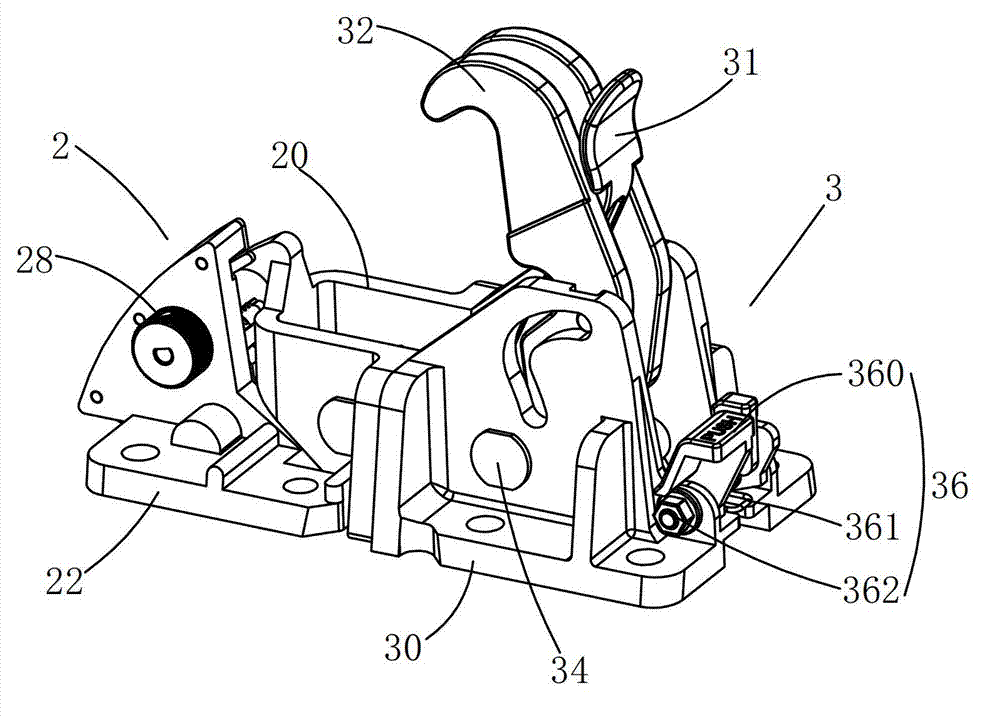

[0057] A display screen quick splicing device provided by a specific embodiment of the present invention is used as follows: figure 1 As shown, it is arranged between two display screen units 1 (or display unit cabinets), and is used for fast fixing and connection between two adjacent display screen units 1 . Depend on figure 1 It can be seen that, by adopting the display screen quick splicing device of this specific embodiment, it can make a certain angle between two adjacent display screen units 1, so that a curved screen can be spliced. Such as Figure 2 to Figure 5 As shown, this kind of display screen quick splicing device includes interlockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com