Light mixing distance experimental device

A technology of light mixing distance and experimental device, applied in the field of backlight, can solve the problems of cumbersome testing procedures and low efficiency, and achieve the effect of facilitating testing and accumulating test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

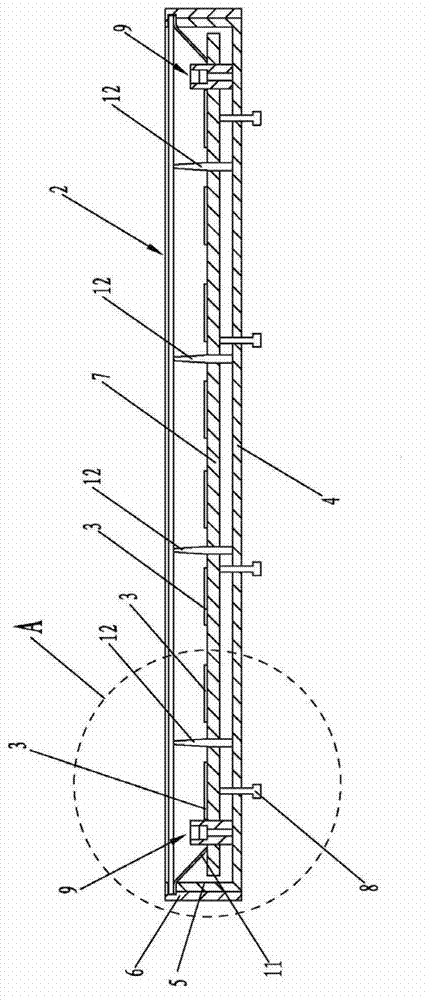

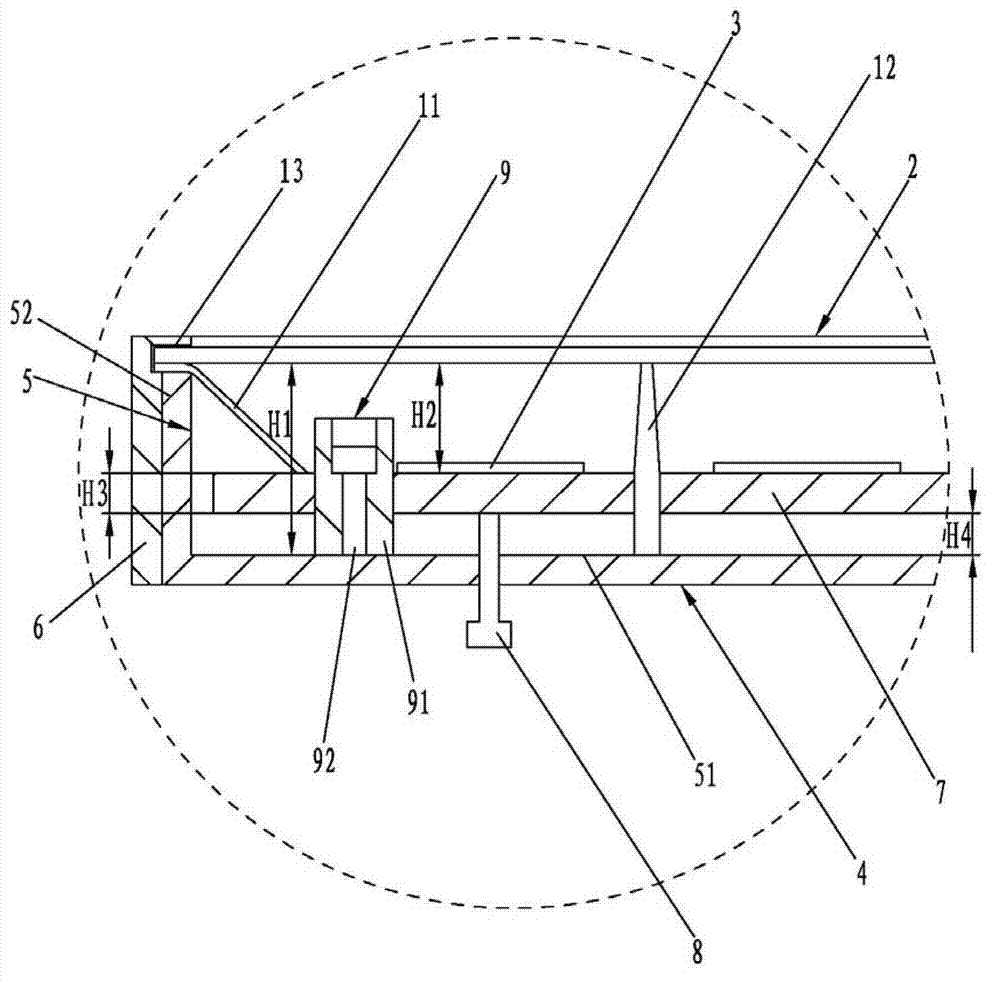

[0020] It should be noted that the light mixing distance in the direct-type backlight module refers to the distance from the bottom reflector or the light source to the film material in the direct-type backlight module, such as figure 1 and figure 2 As shown, the distance from the upper surface of the lifting pallet 7 to the film material 2 is H2, and H2 is the light mixing distance described in the present invention.

[0021] Such as figure 1 , figure 2 As shown, the light mixing distance experimental device of the embodiment of the present invention is used to experiment and determine the light mixing distance of the backlight module. The light mixing distance experimental device of the embodiment of the present invention includes:

[0022] A fixing device for fixing the film material 2 of the backlight module;

[0023] A supporting device for supporting the light source 3 of the backlight module;

[0024] The adjusting device acting on the supporting device is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com