Automatic cleaning equipment for parts with multiple blind holes

An automatic cleaning and blind hole technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low work efficiency, poor cleaning effect, long working hours, etc., and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, the automatic cleaning equipment for multi-blind-hole parts of the present invention will be described in detail with reference to the accompanying drawings and embodiments:

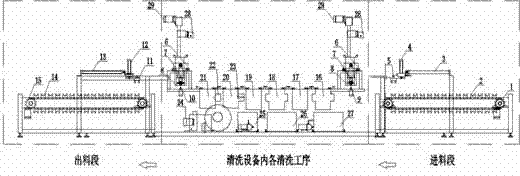

[0036] Such as figure 1 As shown, an automatic cleaning equipment for parts with multiple blind holes includes a feed section, a cleaning equipment section and a discharge section.

[0037] The feeding section includes a feeding motor and a gear 1. The gears in the feeding motor and the gear 1 mesh with the feeding end slot 2. The feeding end transverse movement cylinder 3 and the upper feeding end are arranged directly above the feeding motor and the gear 1. Material end lifting cylinder 4 and feeding manipulator 5.

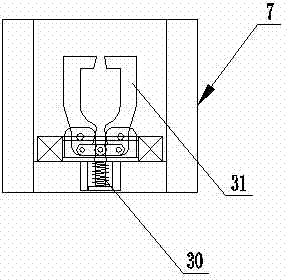

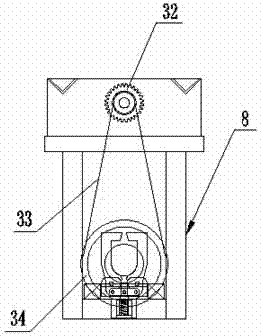

[0038] Each cleaning equipment section includes an internal manipulator 6, a cleaning basket 8 is provided below the internal manipulator 6, a traveling clamp 7 is provided in the cleaning basket 8, and a cleaning basket lifting motor 28 and a cleaning basket are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com