Manufacturing method of ITO target material high-purity nano indium tin oxide powder

A technology of indium tin oxide powder and manufacturing method, which is applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., and can solve problems such as difficult cleaning of inorganic acid ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with embodiment.

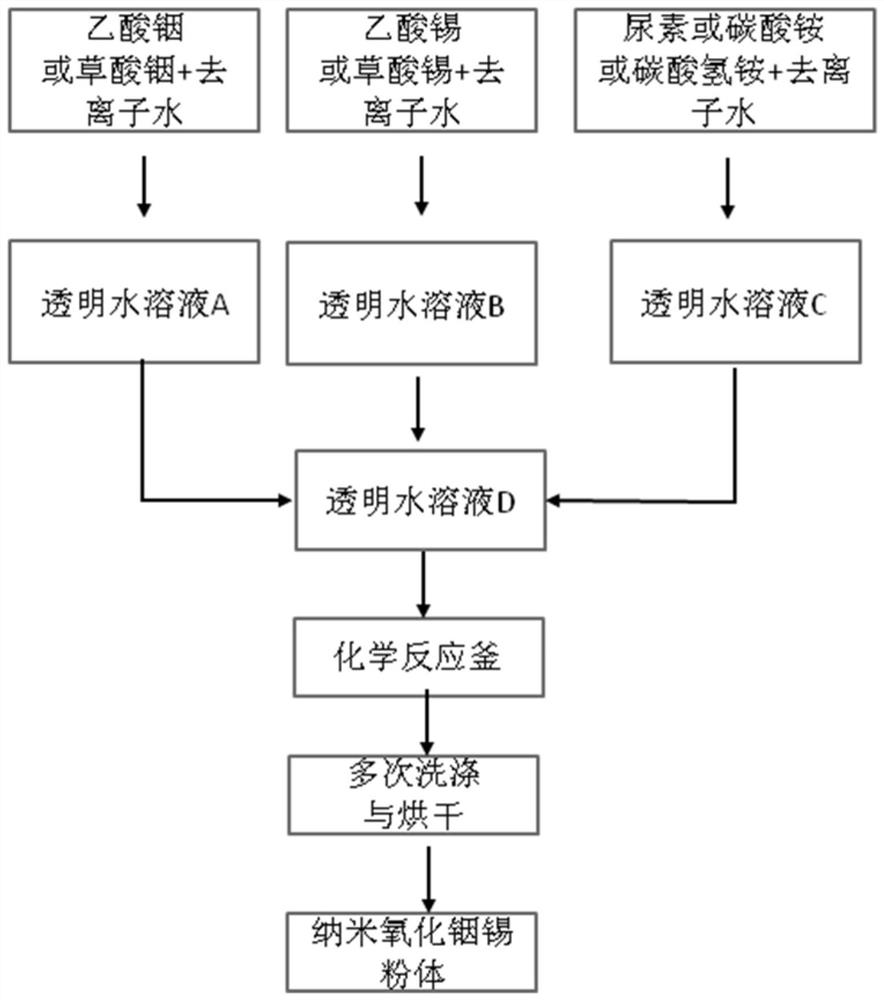

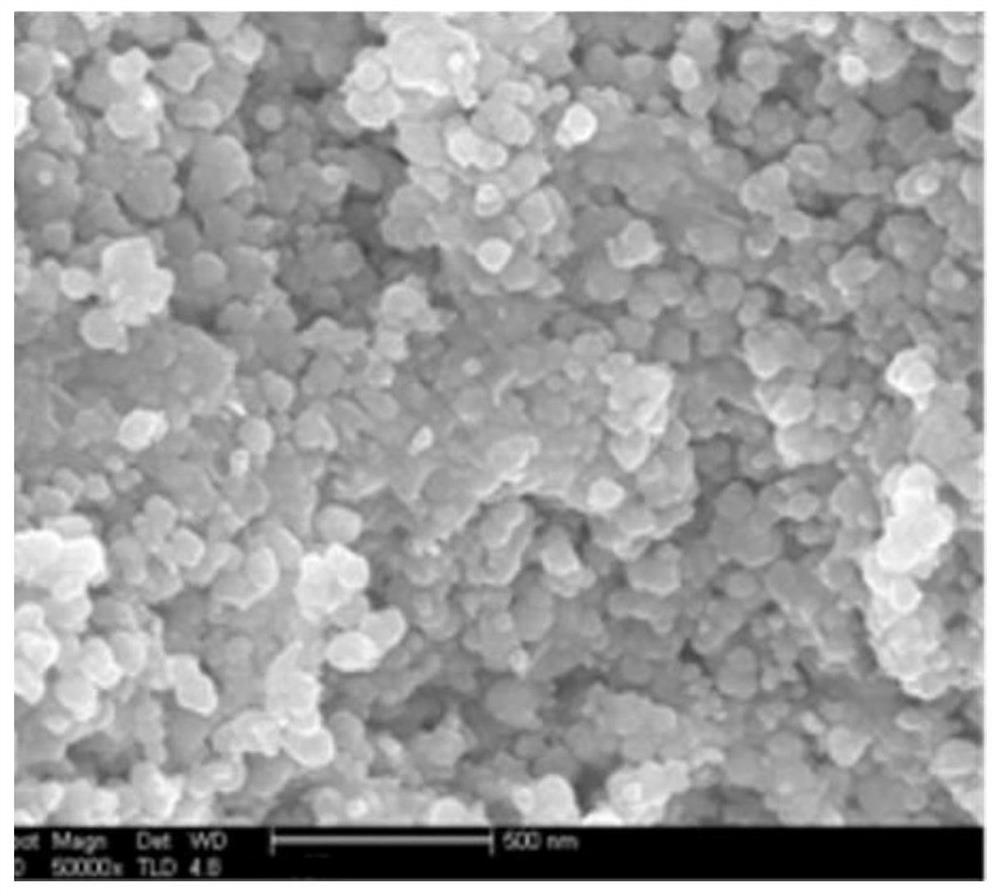

[0020] Such as figure 1 , 2 As shown, a kind of ITO target material high-purity nano indium tin oxide powder manufacturing method provided by the present invention comprises the following steps:

[0021] a. Dissolve indium oxalate (In2(C2O4)3) and tin oxalate (Sn(C2O4)2) in deionized water at a ratio of 8.19:1 or 7.7:1 or 8.7:1 to form a transparent aqueous solution; or indium acetate (In(C2H3O2)3) and tin acetate (Sn(C2H3O2)4) are dissolved in deionized water according to the ratio of 11.89:1 or 11.4:1 or 12.4:1 to form a transparent aqueous solution;

[0022] b. Dissolving urea or ammonium carbonate or ammonium bicarbonate in the above-mentioned deionized water to form a transparent aqueous solution whose concentration is 0.4 or 0.6 or 0.8mol / L;

[0023] c. Mix the above two solutions and transfer them into a reaction kettle, then put the reaction kettle into an oven for hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com