Environment protection type weakly acidic deburring softening solution and preparation method and use method thereof

A weak acid and deburring technology, which is applied in the field of preparation of environment-friendly weak acid epoxy plastic package deburring and softening liquid, can solve the problems of high price, increased pressure, discoloration of plastic package, etc., and achieves convenient waste treatment, stable products, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Preparation of environment-friendly weakly acidic deburring softening solution

[0014] The weight percentage ratio of each component is carried out according to the following ratio: 40% dimethylacetamide, 40% dimethyl sulfoxide, 1% furfural, 0.5% OP-10 surfactant, and the balance is water.

[0015] The preparation process of this embodiment is as follows: according to the above-mentioned component content, add 2 / 3 of the water in the container; when stirring, add dimethylacetamide; when stirring, add dimethyl sulfoxide at a uniform speed, continue Stir for 5-10 minutes; while stirring, add furfural at a constant speed, and continue stirring for 5-10 minutes; while stirring, add OP-10 surfactant, add water to the required amount, and stir evenly.

[0016] The method of use in this embodiment is: first add the environment-friendly weakly acidic deburring and softening solution into the stainless steel tank, raise the temperature to 100-130°C, then put the s...

Embodiment 2-5

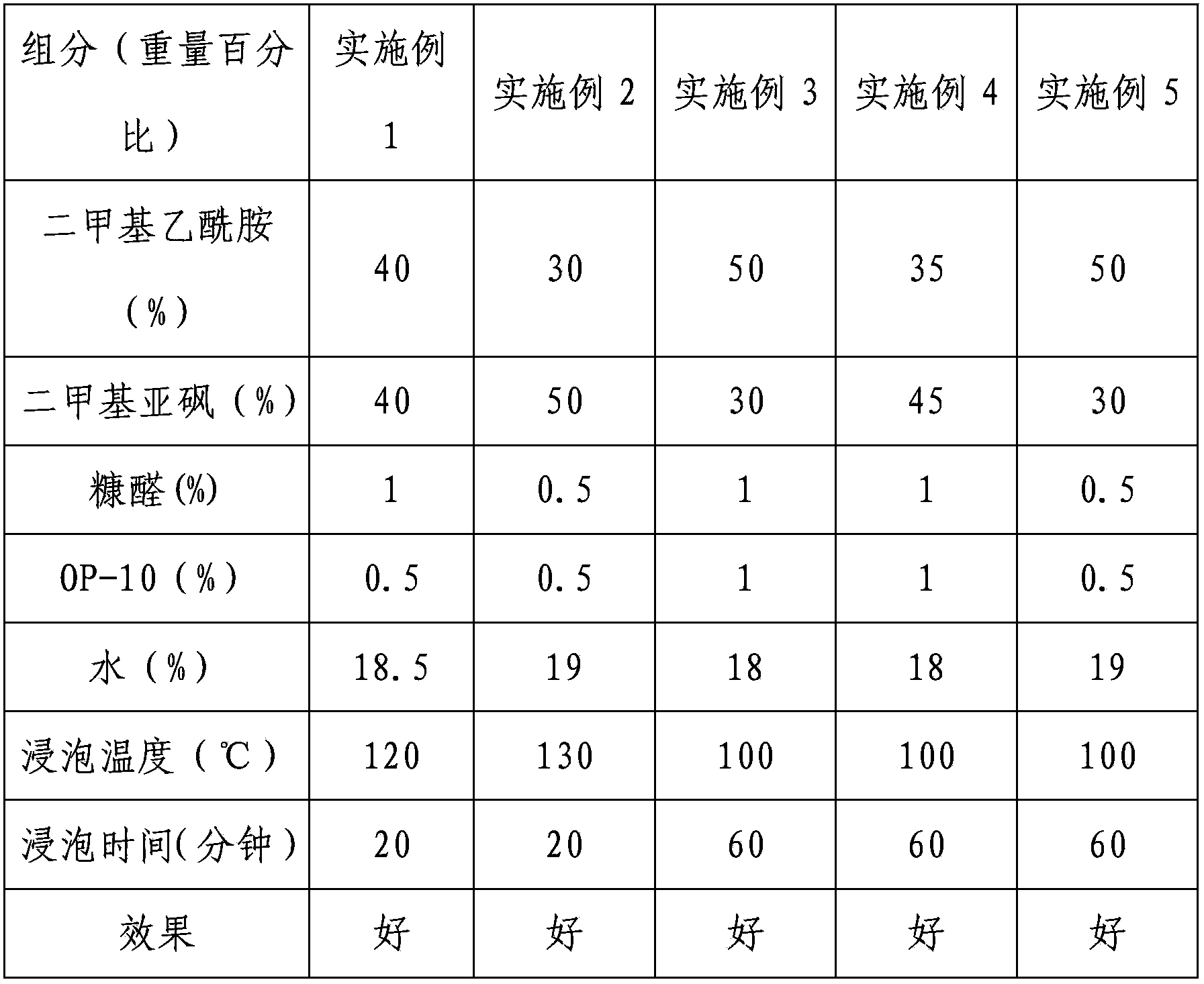

[0018] Repeat the method of Experimental Example 1 according to the content of each component specified in Table 1 below to obtain an environmentally friendly weakly acidic deburring softening solution made of different components. The experimental results are shown in Table 1.

[0019] Table 1 embodiment experiment concrete parameter

[0020]

[0021] It can be seen from the test results shown in Table 1 that the environment-friendly weakly acidic deburring softening solution provided by the present invention can remove burrs and oxides on the surface of the substrate by soaking at 100-130°C for 20-60 minutes, and has excellent The effect of deburring and deoxidation.

[0022] When using this product, avoid bringing in acidic or alkaline solutions, wash your hands after operation, ventilate the workplace and storage warehouse, and avoid contact with the skin or splashing into the eyes. During use, add according to the analysis, or when the pH value of the solution is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com