Gluing connection method for corner combination of broken bridge aluminum doors and windows

A technology for broken bridge aluminum, doors and windows, applied in the direction of windows/doors, building components, buildings, etc., can solve problems such as difficulty in closing, sinking, and poor sealing of window sashes, so as to avoid difficulty in closing, prolong service life, and improve connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

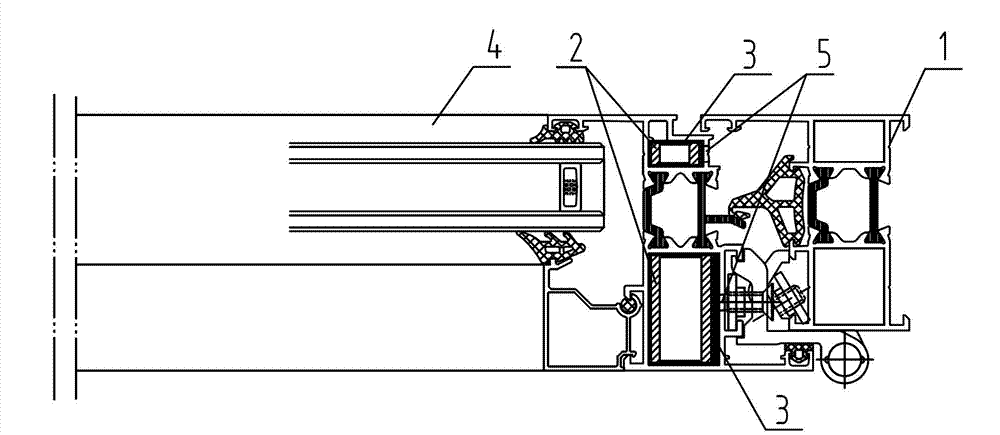

[0014] See figure 1 , figure 2 , which is a structural schematic diagram of an embodiment of the method for connecting the corners of broken bridge aluminum doors and windows with glue injection. In order to improve the connection strength of the door and window frames and prevent the doors and windows from sinking after a period of use, the specific operation steps are as follows:

[0015] 1) During the assembly process of the door and window frame, firstly seal the two sides of the cavity connecting the corner bracket 2 with plastic sheets and then put it into the inner cavity of the horizontal frame profile 4 and the vertical frame profile 1. It is required to connect the corner bracket 2 and the horizontal frame A gap of not less than 0.5mm is provided between the frame profile 4 or the mullion profile 1 profiles, and then the angle extrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com