Tension and compression coupling type high-strength and high-deformation anchor rod and method for using same

A large-deformation, coupling-type technology, applied in the installation of bolts, earthwork drilling, sheet pile walls, etc., can solve the problems of large-deformation bolts with complex structures, difficult to reach, high bearing capacity, etc., to improve reliability and support The effect of protecting, optimizing the stress state, and improving the effect of supporting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

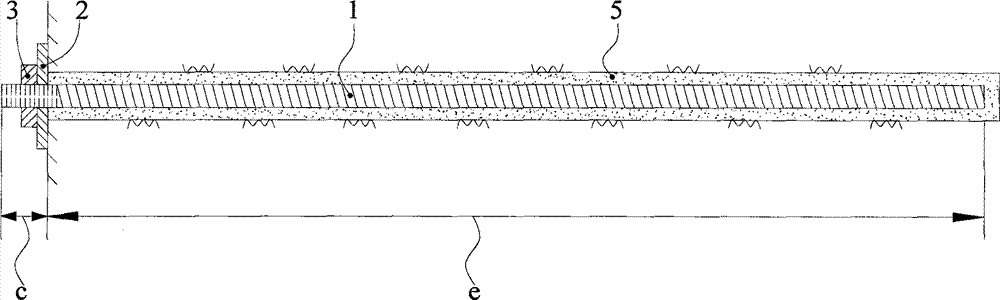

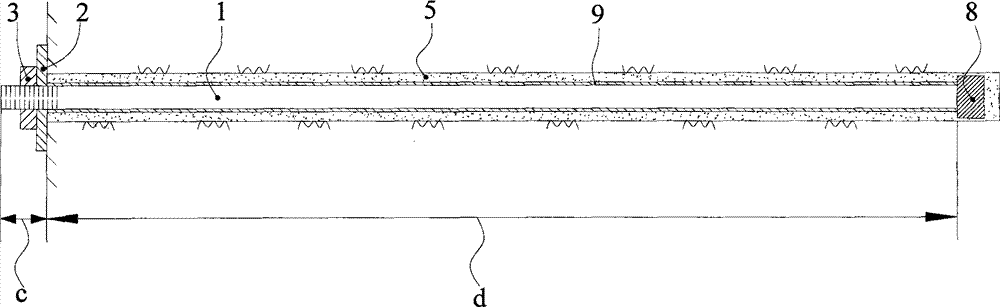

[0041] figure 1 and figure 2 They are respectively the schematic diagrams of the existing tension type anchor rod and the pressure type anchor rod, and their structures will not be described in detail.

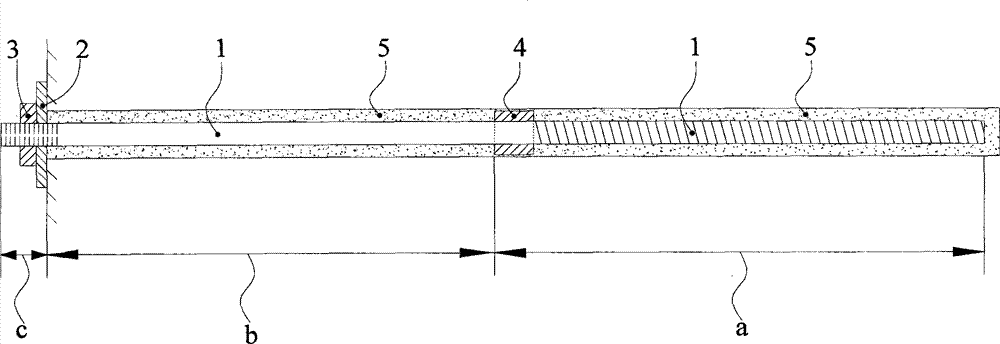

[0042] Combine below Figure 3-Figure 7 The technical solution of the present invention is described.

[0043] Such as image 3 As shown, a tension-compression coupling type high-strength deformation anchor is mainly composed of an anchor body 1, a tray 2 and a nut 3, and the nut 3 outside the hole is used as the outer anchoring section c after being tightened, and the anchoring agent 5 is poured into the hole and then combined with The anchor body 1 is bonded as the inner anchoring section; the surface of the anchor body 1 of the inner anchoring section is in two states, the section near the hole is smooth and round, and the section near the bottom of the hole is rough; smooth and round The rod body constitutes a temporary inner anchoring section b, also known as "quasi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com