Automobile muffler

A technology of automobile muffler and muffler cotton, which is applied to muffler devices, machines/engines, engine components, etc., can solve the problem of insufficient muffling effect and other problems, and achieve the effect of attenuating exhaust noise and reducing radiated noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing:

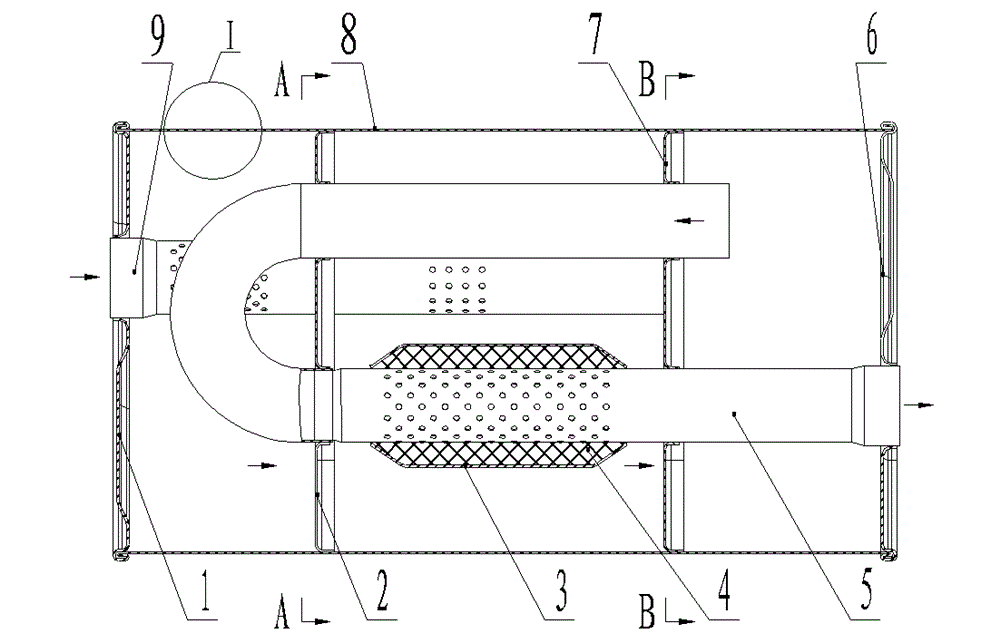

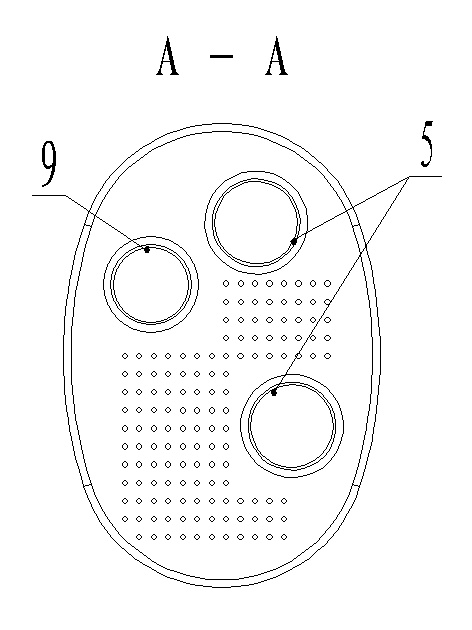

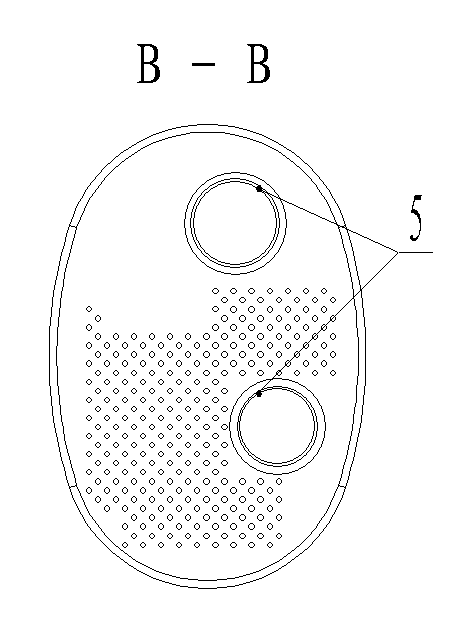

[0014] Such as figure 1 , figure 2 , image 3 The automobile muffler shown has a shell that is connected by crimping between the cylinder body 8 and the front end cover 1 and the rear end cover 5; the cylinder body 8 is surrounded by overlapping two layers of steel plates, as Figure 4 As shown, the connecting longitudinal seam of the cylinder body 8 is surrounded by undercuts, that is, the first edge and the tail edge of the steel plate are connected by one of the sides biting into the groove formed by the other bent side, as shown in Figure 5 shown. In the shell, the front partition plate 2 with holes and the rear partition plate 7 are welded with the cylinder body 8 to divide the internal space into the first, second and third chambers in sequence along the air intake direction; Into the air intake pipe 9 inside the housing, the rear partition 7 seals the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com