Antirust washer

A technology of gaskets and annular grooves, applied in the direction of gaskets, connecting components, engine components, etc., can solve the problems of bolts or nuts rusting, easy to rust, loss, etc., and achieve the effect of solving stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

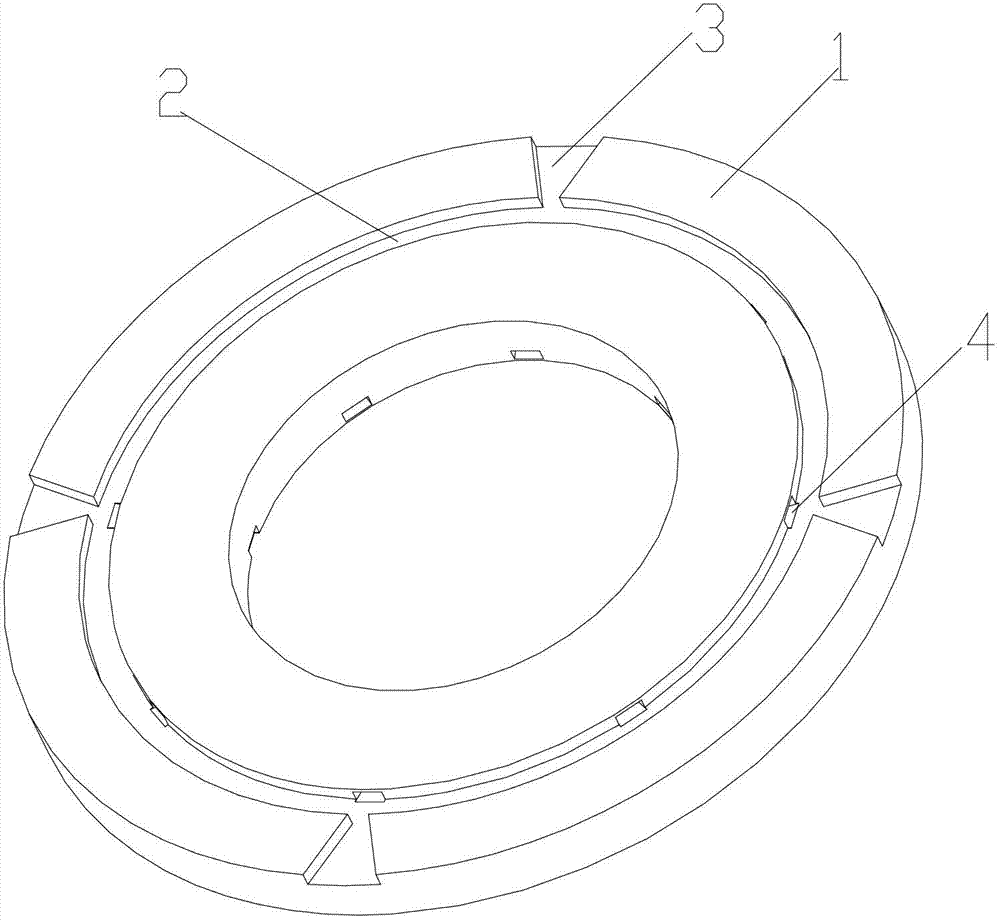

[0013] attached figure 1 It is an anti-rust gasket according to the present invention, which includes a gasket main body 1; an oil guide annular groove 2 is opened on the gasket main body 1; an oil inlet hole 3 is opened on the outer side of the oil guide annular groove 2; The inner side of the annular groove 2 is provided with an oil through hole 4; there is at least one oil inlet hole 3; and there is at least one oil through hole 4.

[0014] The solution of the present invention facilitates the addition of lubricant by setting the oil inlet hole 3 and the oil guide annular groove 2 on the gasket body, and the oil through hole 4 can effectively flow the lubricant into the rusted parts, thus effectively solving the problem of Parts stuck due to rust.

[0015] The above-mentioned embodiments are only to illustrate the technical conception and characteristics of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com