Torque sensor

A torque sensor and stress technology, applied in the field of test measurement, can solve problems such as the inability to guarantee the measurement accuracy and the inability to measure the torque of the object to be measured, and achieve the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Describe the present invention below in conjunction with specific embodiment:

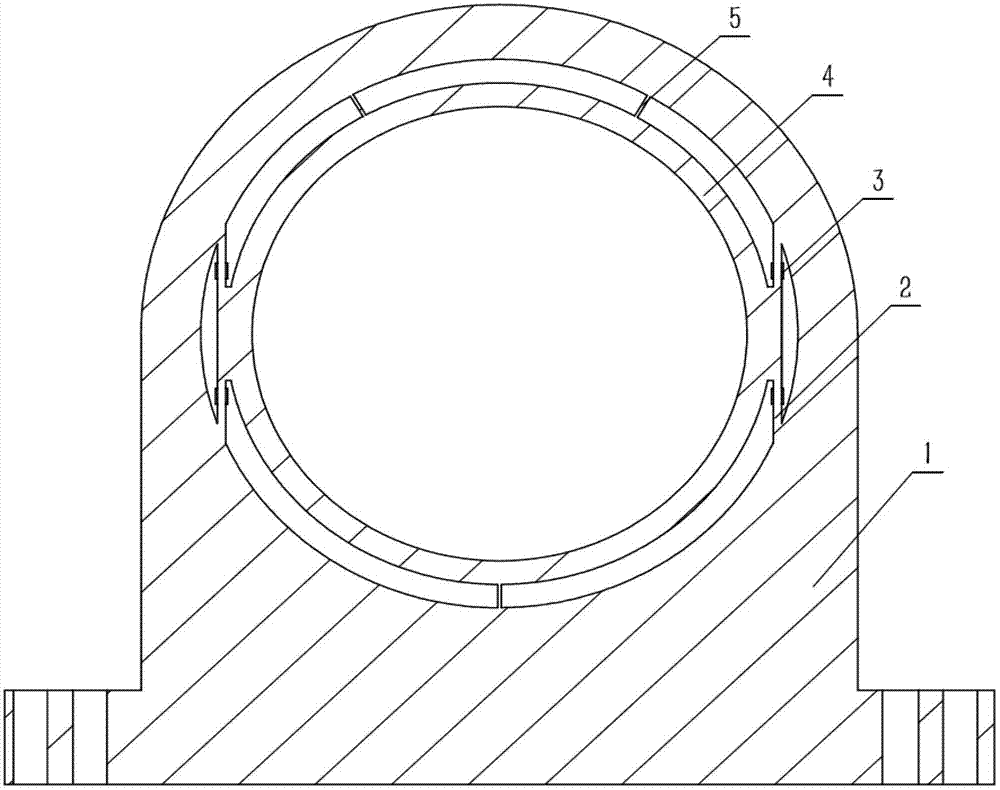

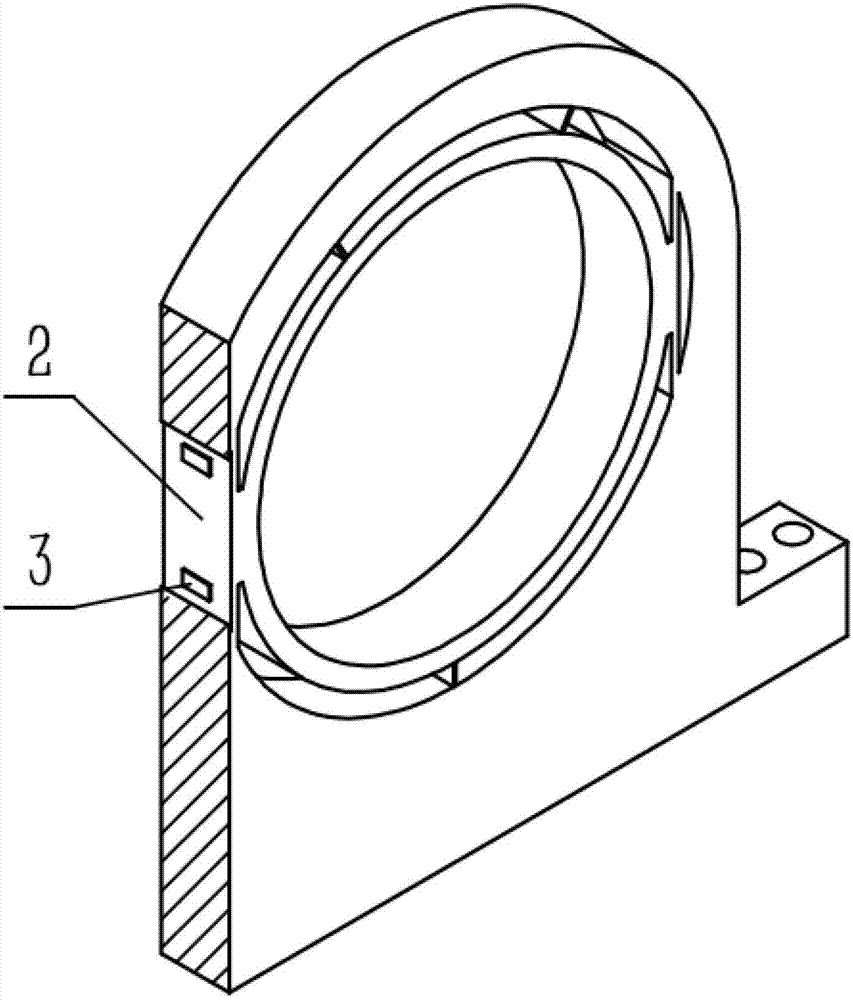

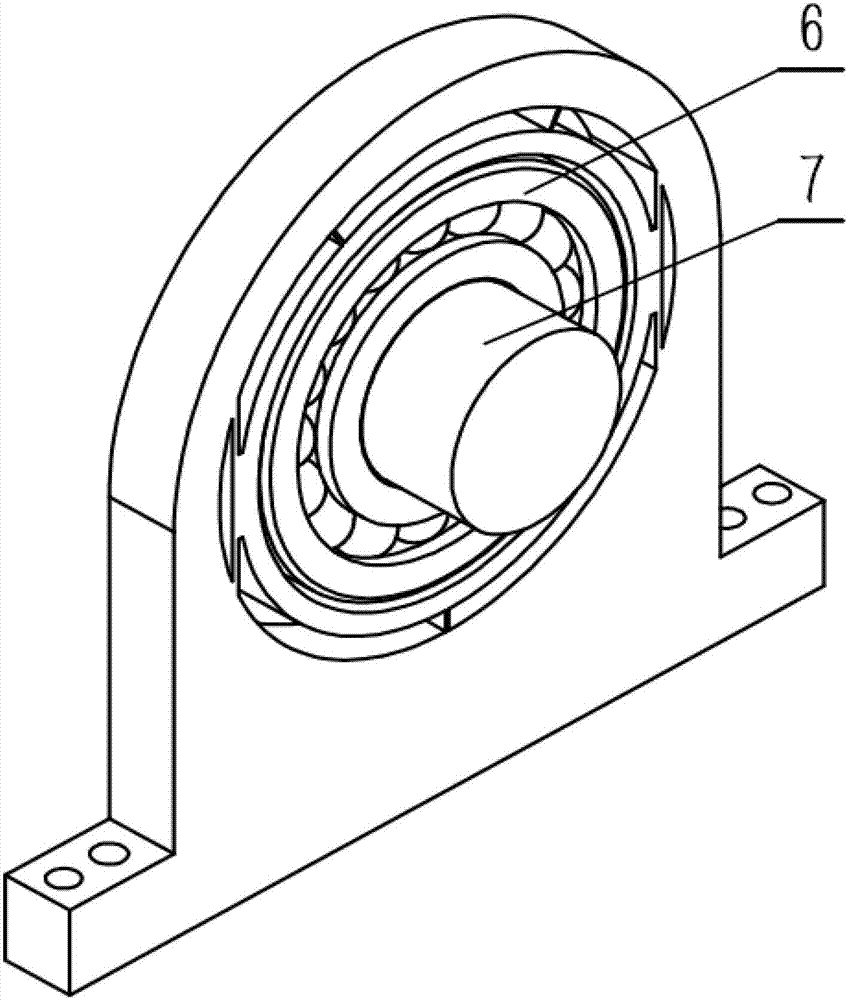

[0015] The torque sensor in this embodiment is composed of a support seat 1 , a stress plate 2 , a sleeve 4 , a thin-walled plate 5 and a resistance strain gauge 3 .

[0016] Refer to attached figure 1 , The support seat 1, the stress plate 2 and the sleeve 4 are integrally formed structures. The sleeve 4 is coaxially and fixedly connected with the support seat 1 through the stress plates 2 tangentially on both sides. In this embodiment, the stress plate 2 is vertically located at the left and right ends of the sleeve 4, and connects the sleeve 4 and the supporting seat 1 together. The stress plates on both sides are symmetrical with respect to the central axis of the sleeve, and the outer surfaces of the stress plates on both sides are tangential planes to the edge of the sleeve. The thickness of the stress plates is between 2 mm and 5 mm to ensure the accuracy of measurement. In this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com