Method for evaluating protective capability of weathering steel rust layers based on freezing-unfreezing treatment

A technology of protection ability and evaluation method, applied in the field of corrosion of iron and steel materials in the atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the method for evaluating the protection ability of the weathering steel rust layer based on freezing-thawing treatment comprises the following steps:

[0023] Step 1. Obtain a variety of weathering steel samples with rust layers to be tested;

[0024] Step 2. Carry out freezing-thawing treatment to the weathering steel sample, the freezing-thawing treatment is to soak the weathering steel sample in deionized water for 30 minutes, so that the rust layer absorbs enough water, and then take it out until the surface does not drip Put it in a freezer with a temperature of -18°C and freeze it for 1 hour, then take it out and put it in a drying oven at 25°C for 24 hours;

[0025] When freezing and thawing the weathering steel samples, the rust layer of the weathering steel samples can absorb enough water by spraying the weathering steel samples instead of immersing the weathering steel samples;

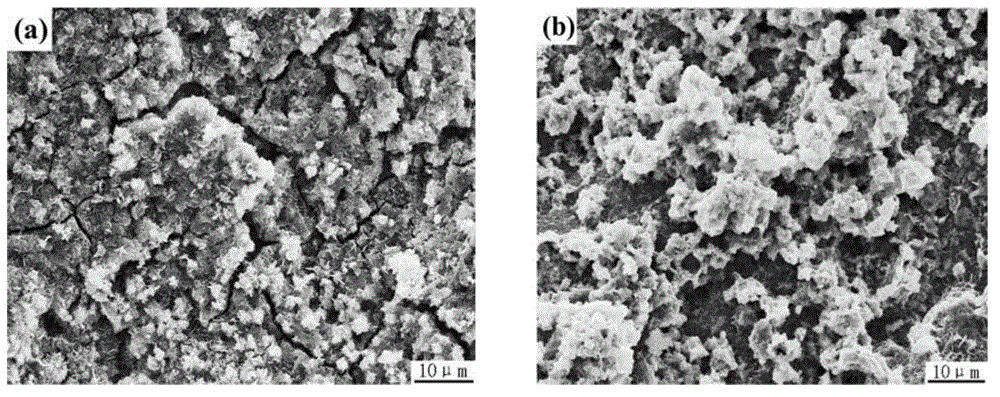

[0026] Step 3. Utilize the scanning electron microscope to ...

Embodiment 2

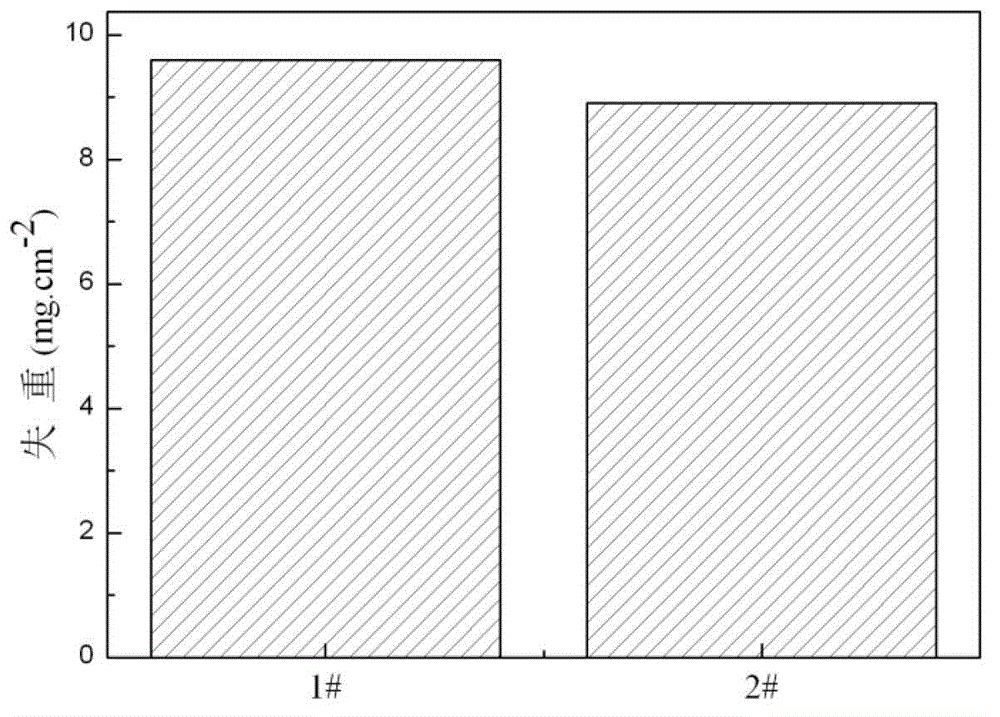

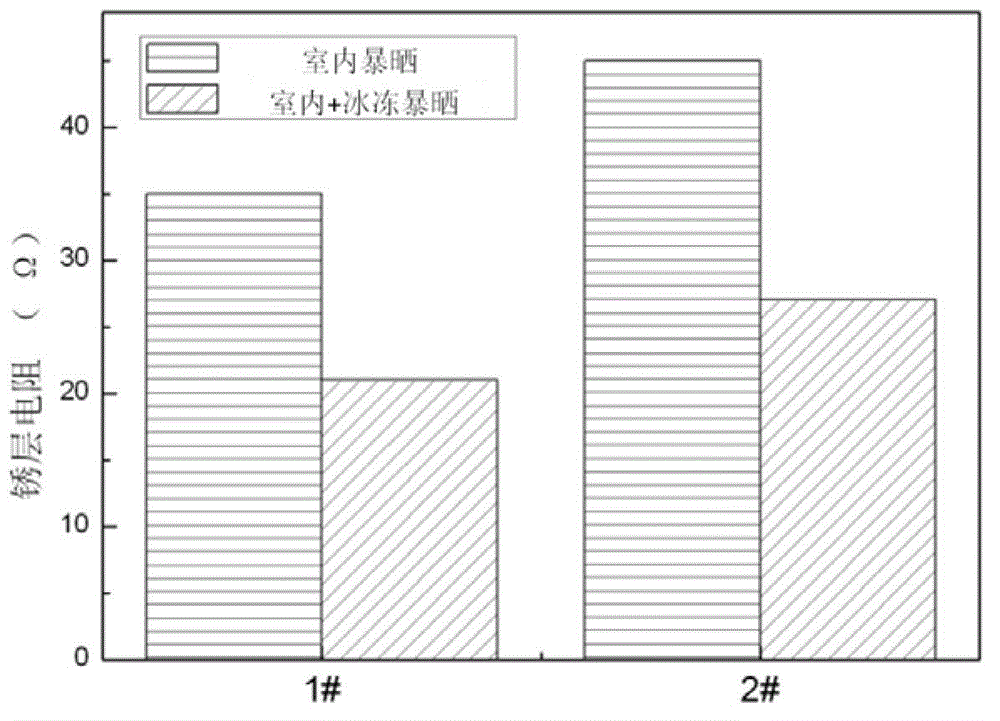

[0031] Select 1# and 2# two test steels with different chromium content and the same other components (see Table 1 for the composition of the test steel):

[0032] Steel C mn Si S P Cu Cr Ni Bt 1 # 0.045 0.86 0.32 0.0052 0.0055 0.48 0.96 0.37 0.0014 2 # 0.051 0.85 0.33 0.0045 ﹤0.005 0.48 1.46 0.36 0.0013

[0033] Table 1 Chemical composition of test steel (wt%)

[0034] Samples with dimensions of 10 mm × 10 mm × 5 mm and 60 mm × 40 mm × 5 mm were cut from the as-rolled steel plate for accelerated spray test. Each test steel is divided into two groups in parallel, and the two groups of samples are placed in the test room for exposure. The exposure frame faces the south at 45o to the horizon and is exposed to sunlight. %about. One group of test steels was subjected to freezing-thawing treatment. After being sprayed for half an hour every day, they were placed in a freezer maintained at -18°C for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com