Method for producing pneumatic tire

A manufacturing method and technology of pneumatic tires, applied in the field of pneumatic tire manufacturing of pneumatic tires, can solve problems such as unfavorable tire weight reduction, achieve stable inflation and improve consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Next, the method of manufacturing the pneumatic tire of the present invention will be described based on the embodiment shown in the drawings. Furthermore, the same reference numerals are used for the same components before and after vulcanization.

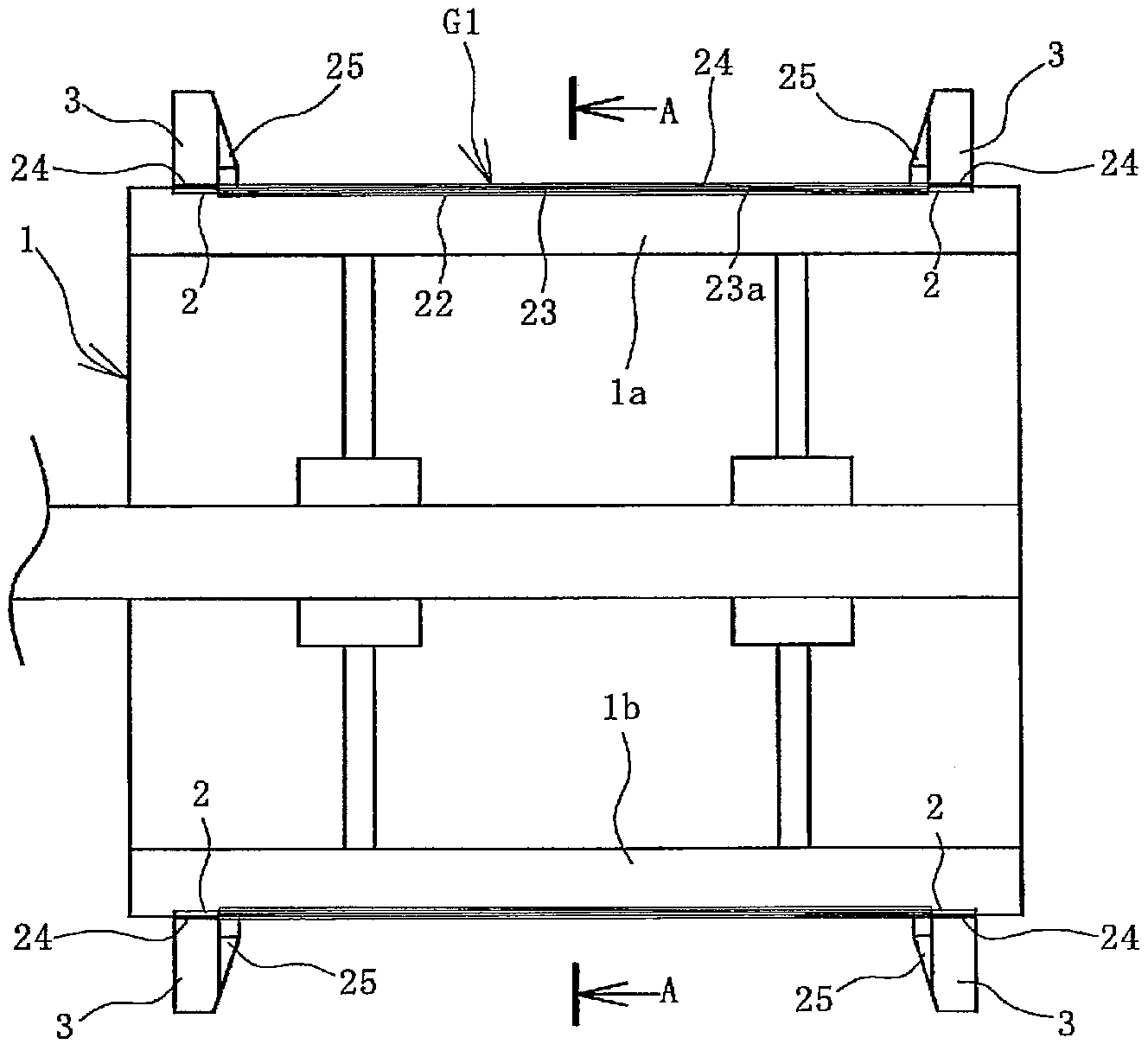

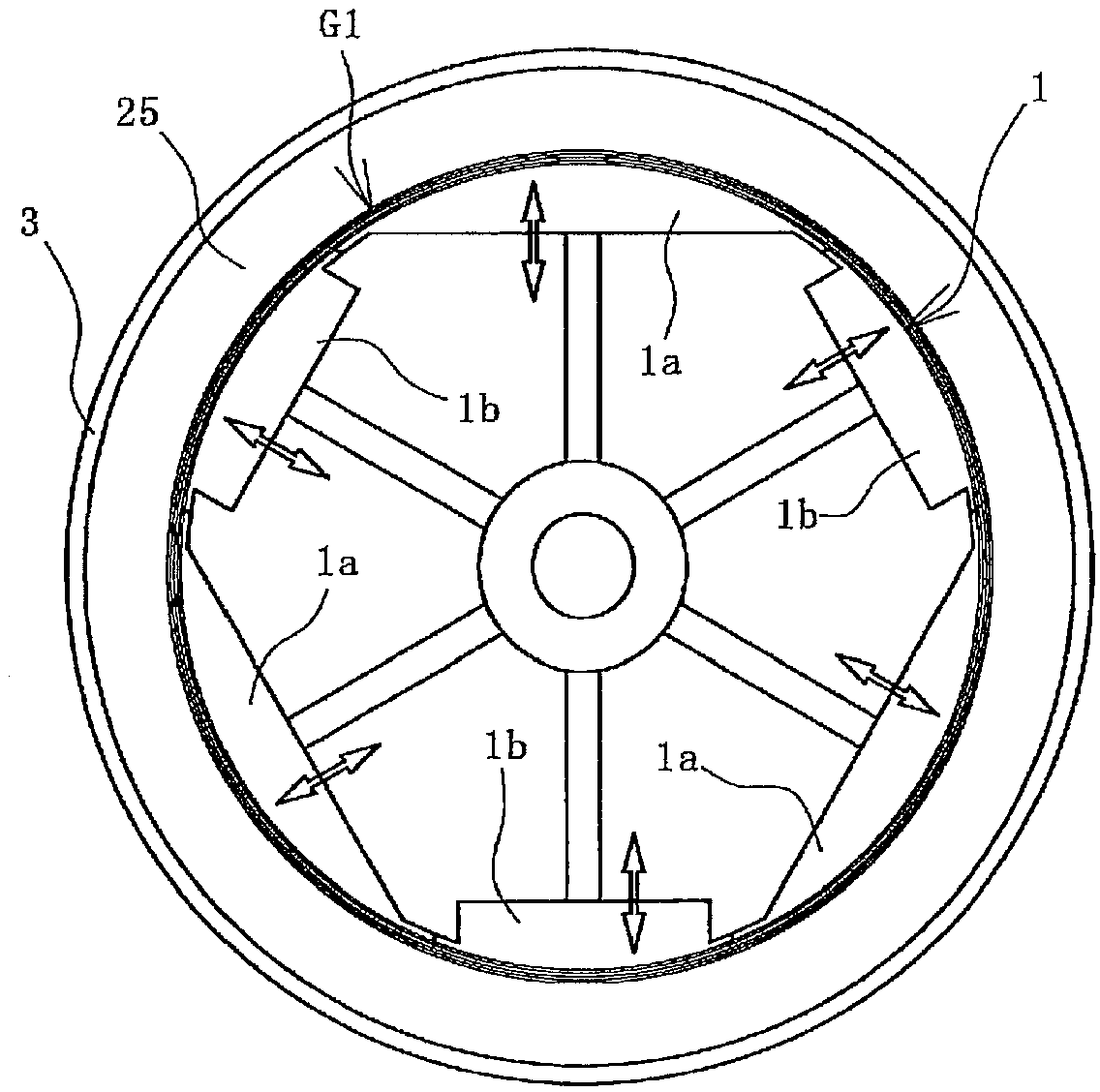

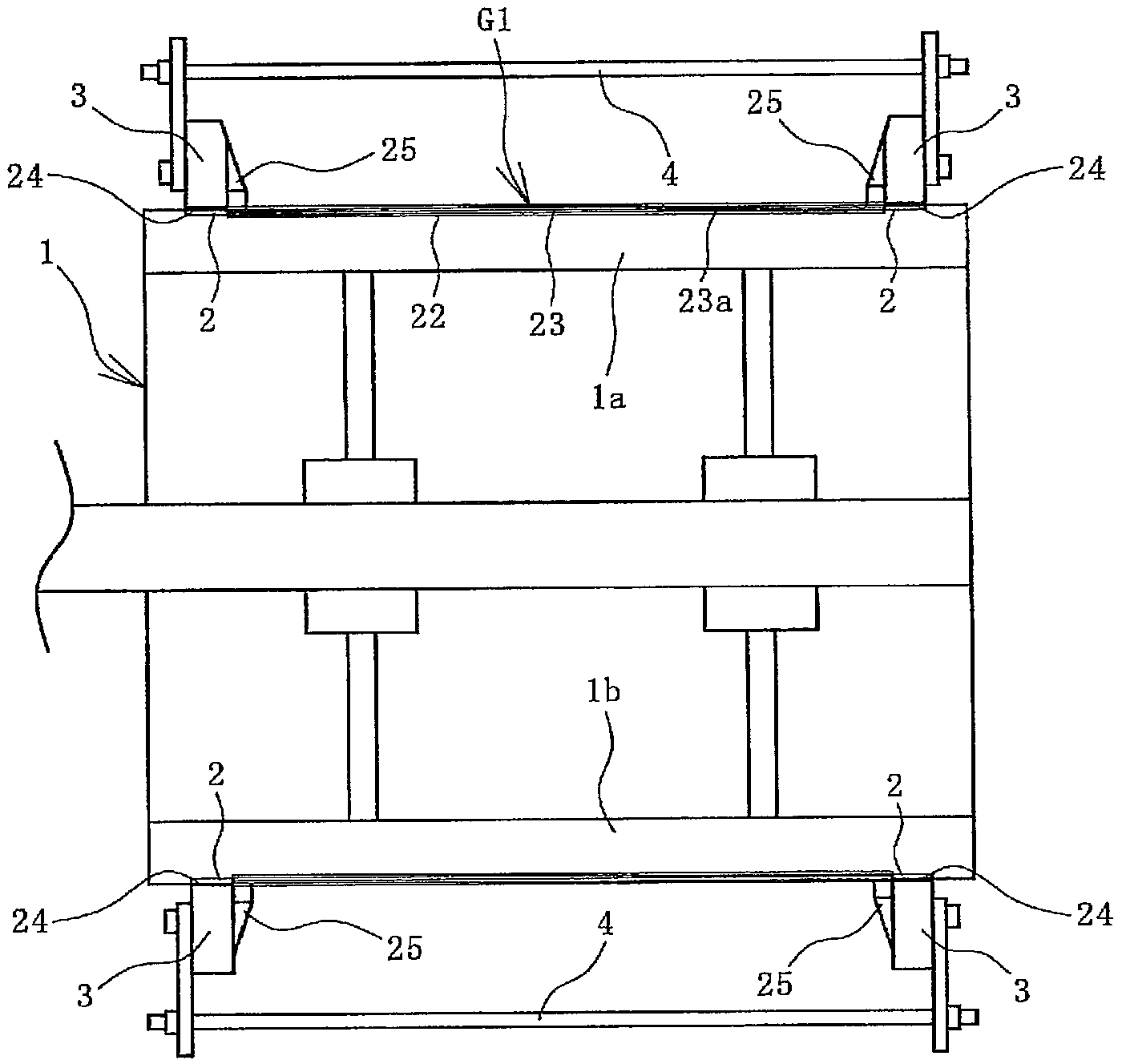

[0046] Figure 18The pneumatic tire 21 manufactured according to the present invention is exemplified in . In this pneumatic tire 21 , a carcass 24 is spanned between a pair of bead rings 25 , and the carcass 24 is folded back to the outside from inside around a bead core 25 a with a bead filler 25 b interposed therebetween. On the inner peripheral side of the carcass material 24, the joint rubber 23a, the film 23, and the inner liner 22 are laminated in this order. The innermost lining 22 is vulcanized butyl rubber, which together with the membrane 23 prevents air from penetrating. The thickness of the lining 22 is, for example, 0.2 mm to 2.5 mm, and the thickness of the film 23 is, for example, 0.005 mm to 0.2 mm.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com