Cleaning disinfectant for food equipment

A technology for food equipment and disinfectants, applied in the directions of disinfectants, botanical equipment and methods, biocides, etc., can solve the problems of being in the initial stage, the metal is severely corroded, irritating, etc., and achieves simple and easy preparation and killing. significant effect

Inactive Publication Date: 2013-01-16

QINGDAO SANDING SANITARY PROD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the field of food production and disinfection, the main disadvantages of chemical disinfectants represented by sodium hypochlorite are poor stability, short shelf life, oxidative decolorization and denaturation of food, severe corrosion to metals, irritation to human skin, and chemical reactions in the environment or food. Organic chlorine, such as chloroform, has been proved by medical experiments to be the c

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

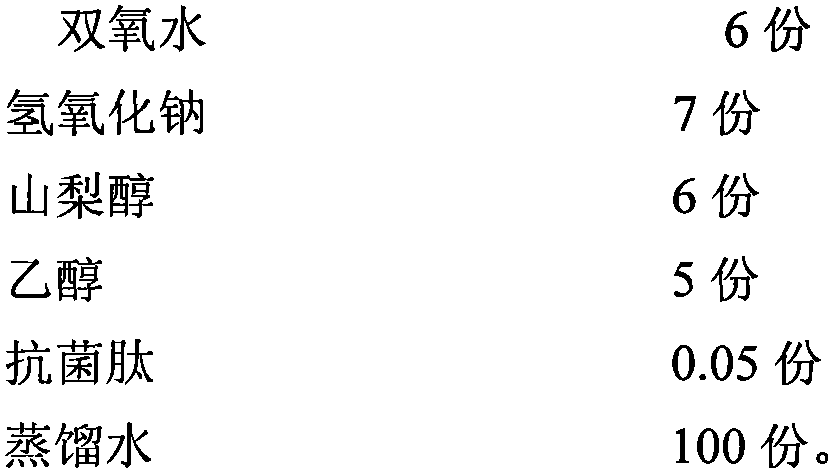

Embodiment 1

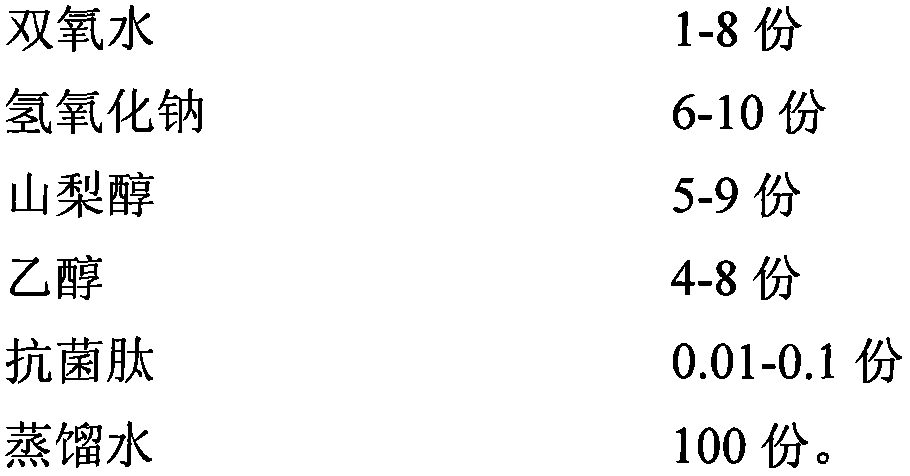

[0012] A cleaning and disinfecting agent for food equipment, comprising the following substances in parts by weight:

[0013]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses a cleaning disinfectant for food equipment. The cleaning disinfectant belongs to the field of food disinfection. The cleaning disinfectant comprises the following components in part by weight: 1 to 8 parts of hydrogen peroxide, 6 to 10 parts of sodium hydroxide, 5 to 9 parts of sorbitol, 4 to 8 parts of ethanol, 0.01 to 0.1 part of antimicrobial peptide, and 100 parts of distilled water. By utilizing a biologic disinfection material such as antimicrobial peptide, the cleaning disinfectant has a remarkable extermination effect on harmful microorganisms on the surface of the food equipment, does not contain chemicals with great harm to a human body, and is simple and easy to prepare.

Description

technical field [0001] The invention relates to a cleaning and disinfecting agent for food equipment. Background technique [0002] In food production, the requirements and standards for disinfection and sanitation work are constantly improving. Sodium hypochlorite is not allowed to be used as a food disinfectant in the Ministry of Health document "Ministry of Health Cancellation of Sanitation Administrative License for Disinfectants with Sodium Hypochlorite as the Main Active Ingredient and Glutaraldehyde as the Main Active Ingredients Disinfectant (No. 8, 2010)". In the field of food production and disinfection, the main disadvantages of chemical disinfectants represented by sodium hypochlorite are poor stability, short shelf life, oxidative decolorization and denaturation of food, severe corrosion to metals, irritation to human skin, and chemical reactions in the environment or food. Organic chlorine, such as chloroform, has been proved by medical experiments to be the c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): A01N59/00A01P1/00

Inventor 邵绪霞

Owner QINGDAO SANDING SANITARY PROD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap