Manufacture Technology of Composite Material Small Box

A composite material and manufacturing process technology, which is applied in the field of manufacturing small box-shaped parts of composite materials, can solve problems such as insufficient pressurization pressure of soft molds, uneven thickness of parts, and difficult control of transfer effects, so as to avoid unstable effects , reduce production costs, and avoid tooling scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

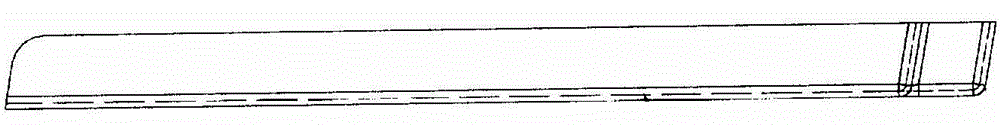

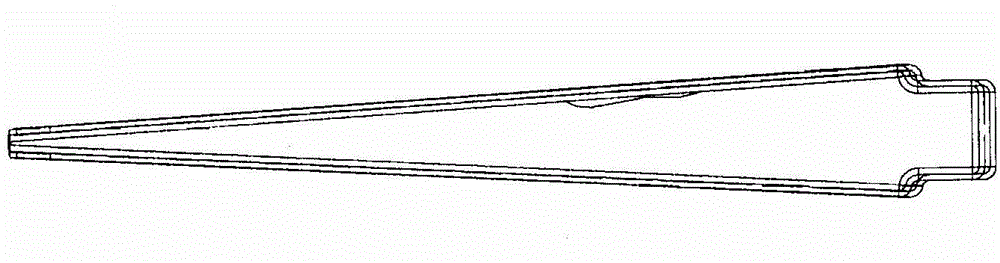

[0025] like image 3 and Figure 4 As shown, the manufacturing process of the small box of composite materials includes the following steps:

[0026] 1) Manufacture of mould: manufacture two sets of forming tooling, male mold and process cover plate;

[0027] 2) Lamination: lamination of composite small box-shaped parts on the male mold;

[0028] 3) Molding: The process cover covers the composite material small box and male mold inside.

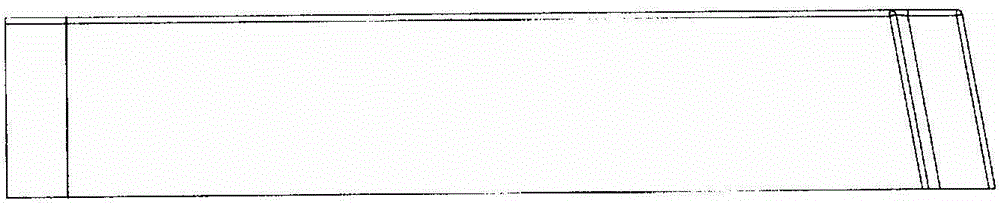

[0029] like Figure 5 As shown, the manufacturing method of the process cover plate is as follows:

[0030] 1) Select 2 layers of AIRPAD rubber 3 and 6 layers of carbon fiber prepreg 4 to mix and cure to form a process cover plate. The process cover plate is disconnected at the end seal 1 and overlapped by 10mm. The hole isolation film is isolated, and the overlapping area 2 is formed at the end, and the process cover plate is consistent with the structure of the composite material small box;

[0031] 2) After the process cover is laid ...

Embodiment 2

[0034] like image 3 and Figure 4 As shown, the manufacturing process of the small box of composite materials includes the following steps:

[0035] 1) Manufacture of mould: manufacture two sets of forming tooling, male mold and process cover plate;

[0036] 2) Lamination: lamination of composite small box-shaped parts on the male mold;

[0037] 3) Molding: The process cover covers the composite material small box and male mold inside.

[0038] like Figure 5 As shown, the manufacturing method of the process cover plate is as follows:

[0039] 1) Select 2 layers of AIRPAD rubber 3 and 6 layers of carbon fiber prepreg 4 to mix and cure to form a process cover plate, disconnect the process cover plate at the end seal 1, and overlap 12.5mm, and use it between the upper and lower layers at the overlap The non-porous isolation film is isolated, and the overlapping area 2 is formed at the end, and the process cover plate is consistent with the structure of the composite materi...

Embodiment 3

[0043] like image 3 and Figure 4 As shown, the manufacturing process of the small box of composite materials includes the following steps:

[0044] 1) Manufacture of mould: manufacture two sets of forming tooling, male mold and process cover plate;

[0045] 2) Lamination: lamination of composite small box-shaped parts on the male mold;

[0046] 3) Molding: The process cover covers the composite material small box and male mold inside.

[0047] like Figure 5 As shown, the manufacturing method of the process cover plate is as follows:

[0048] 1) Select 2 layers of AIRPAD rubber 3 and 6 layers of carbon fiber prepreg 4 to mix and cure to form a process cover plate. The process cover plate is disconnected at the end seal 1 and overlapped by 15mm. The hole isolation film is isolated, and the overlapping area 2 is formed at the end, and the process cover plate is consistent with the structure of the composite material small box;

[0049] 2) After laying up the process cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com