Spiral extrusion device

A technology of screw extrusion and extrusion cavity, which is applied in the field of screw extrusion device and solid-liquid separation equipment, and can solve the problems of exceeding the effective range of the liquid-contacting container, hidden dangers, and the safety of polluted equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

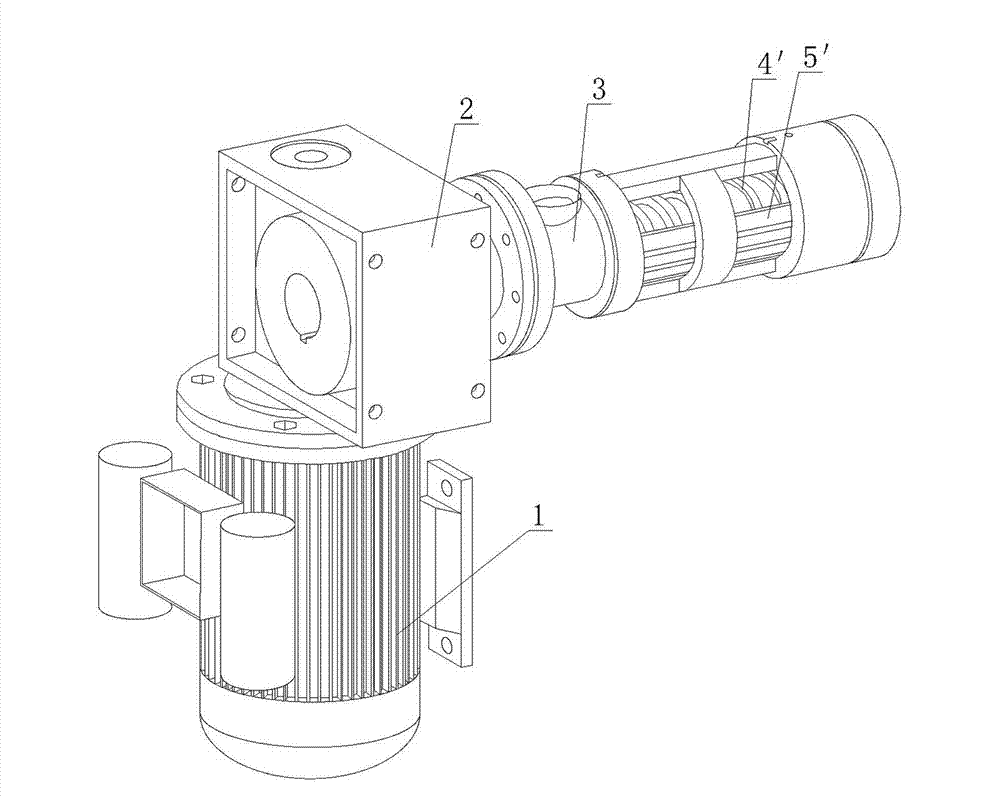

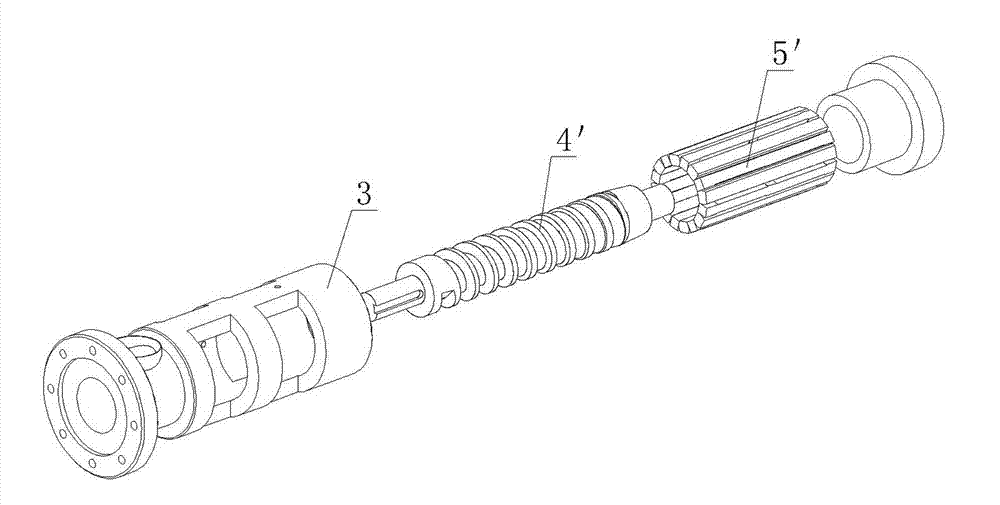

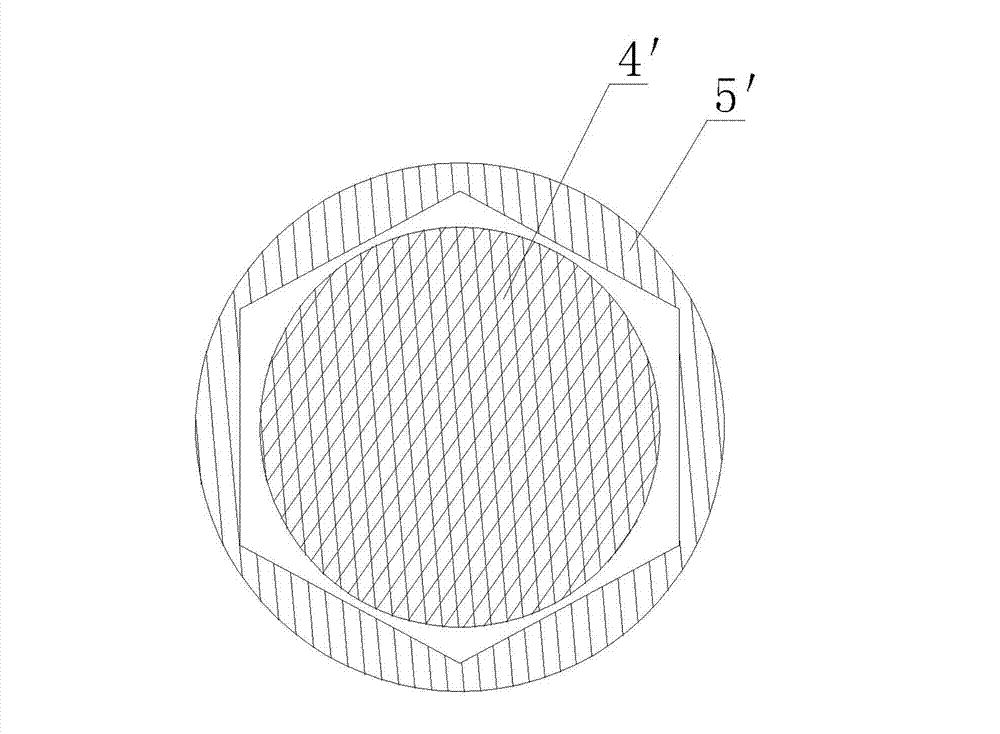

[0018] Such as Figure 4-Figure 8 As shown, the screw extrusion device of the present invention mainly includes a motor 1 and a reduction box 2, a frame body 3, an extrusion screw 4, and an extrusion chamber 5 with several extrusion grooves 51, wherein the reduction box 2 and the motor 1 connection, the extrusion screw 4 is set in the extrusion chamber 5, and the extrusion screw 4 is connected with the output shaft of the reduction box 2 and driven by the reduction box 2 to rotate in the extrusion chamber 5, each screw of the extrusion screw 4 The outer peripheral surface of the bar is processed into a polygonal structure, and the inner peripheral surface of the extrusion chamber 5 is processed into a peripheral surface structure matched with the extrusion screw 4 . Because the present invention skillfully adopts the structure combining the extruding screw rod 4 having a polygonal structure and the extruding cavity 5 having a cylindrical structure, the extrusion function of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com