Three-dimensional carving machine for wood

A three-dimensional engraving and engraving machine technology, applied in the field of wood processing, can solve the problems of high production cost, low strength, poor stability, etc., and achieve the effect of low production cost, high clamping strength and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

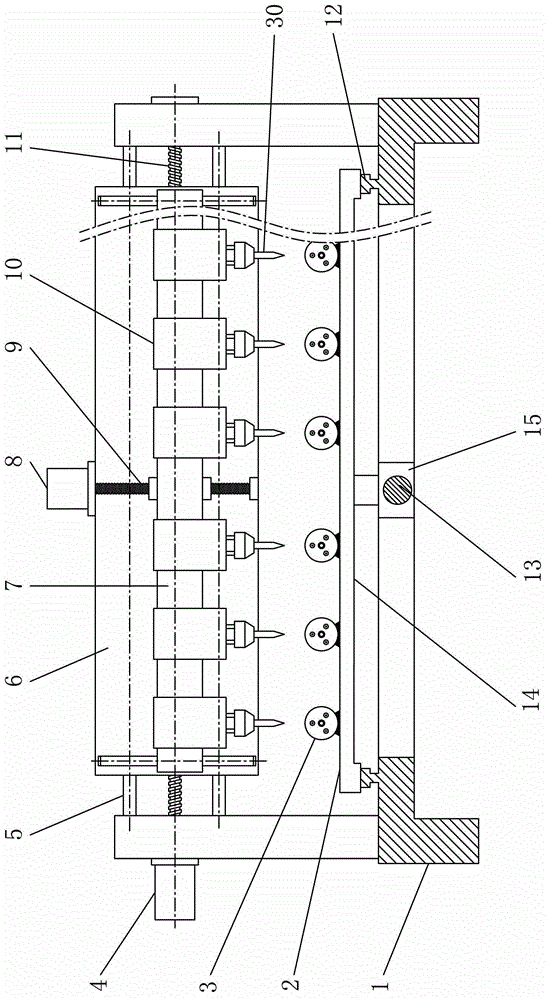

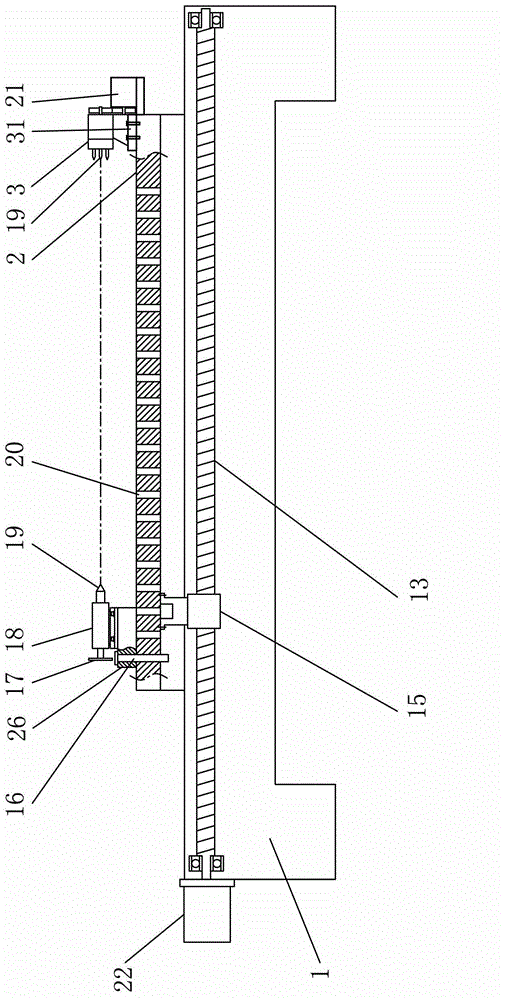

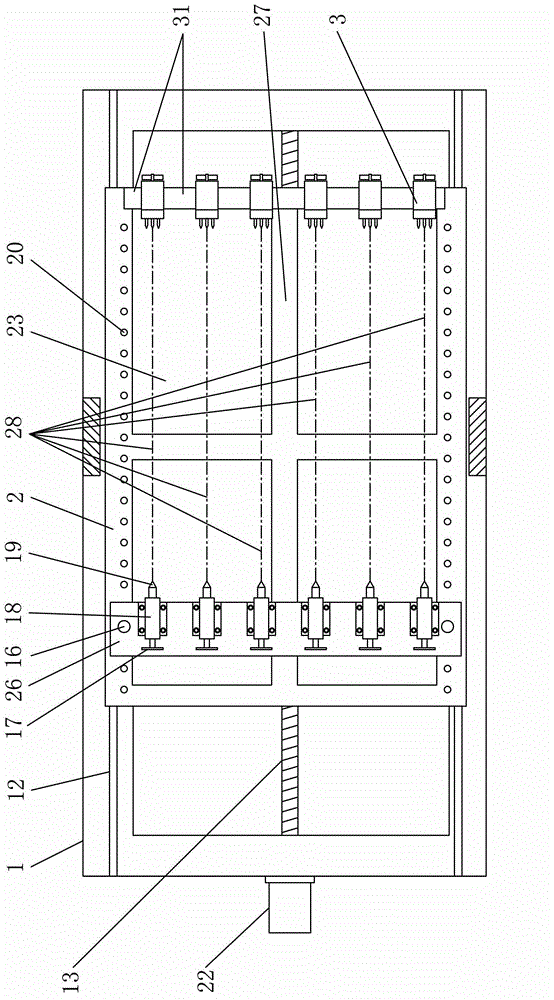

[0017] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3:

[0018] Wood three-dimensional engraving machine, the crossbeam 5 on the upper side of the machine base 1 is provided with a horizontally moving horizontal support plate 6, the horizontal support plate 6 is provided with a vertical support plate 7 that moves up and down, and the vertical support plate 7 is provided with more than one tool 30, the tool 30 is driven by the motor 10 to rotate, and the machine base 1 is provided with a longitudinally movable working platform 2 of the longitudinal carriage, and two rows of thimbles that can move relatively are arranged at both ends of the working platform 2 of the longitudinal carriage 3, 18, two rows of thimbles 3, 18 correspond one-to-one, a row of thimbles 3 is fixed on a common first thimble seat 31 and driven by power 21 to rotate, the first thimble seat 31 is fixed on the longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com