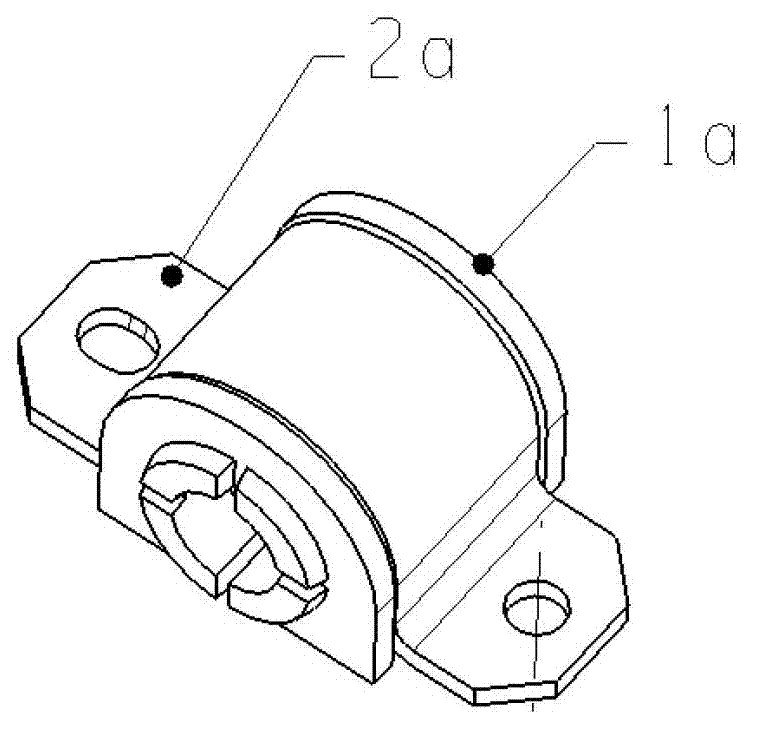

Stabilizer bar bush assembly

A technology for a stabilizer bar bushing and assembly, which is applied in the field of automobile front stabilizer bar bushing assemblies, can solve the problems of short service life, unreasonable position, and wear of the bushing, so as to improve the service life and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

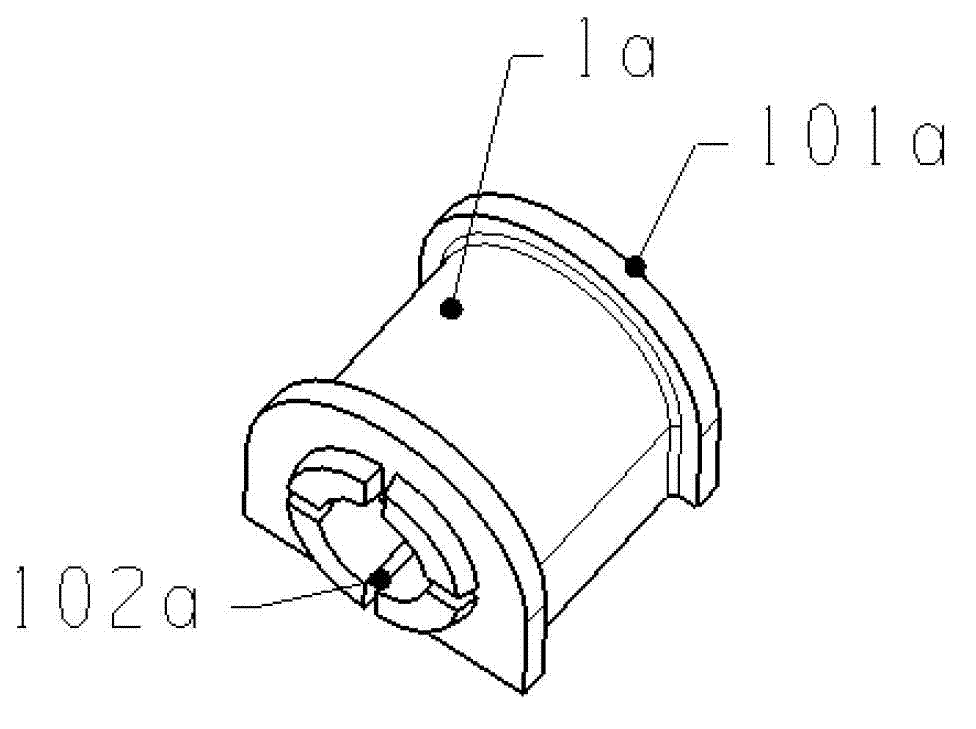

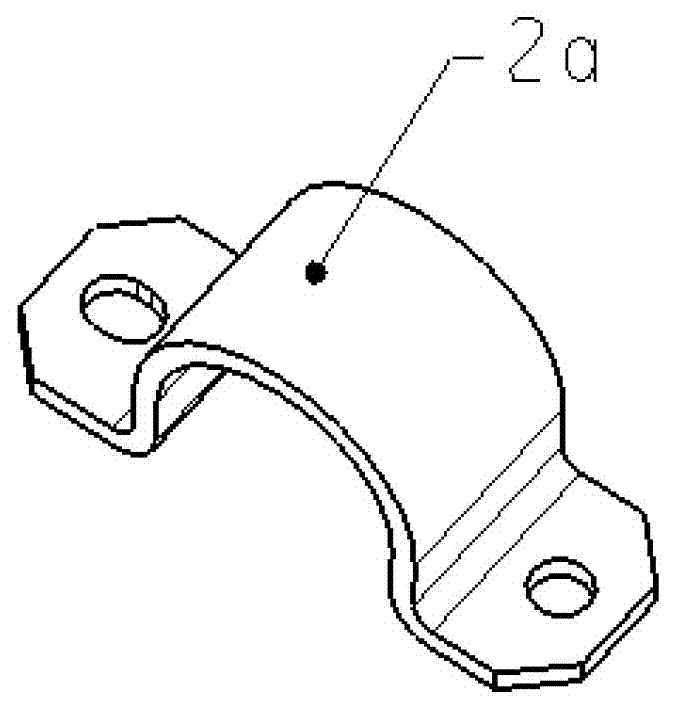

[0031] A stabilizer bushing assembly, including a stabilizer bushing 1c and a pressure block 2c (see Figure 5 ), the bushing of the stabilizer bar is made of rubber, and the pressure block is made of iron;

[0032] like Figure 5 , Figure 6-1 to Figure 6-5 , Figure 7-1 to Figure 7-5 As shown, the two ends of the stabilizer bar bushing 1c have transition large-arc flanging 101c, and there are also transitional large-arc flangings on both sides of the pressure block that closely match the transitional large-arc flanging at both ends of the stabilizer bar bushing. side 201c; under normal circumstances, the radian R of the flanging 101c of the large circular arc at both ends of the stabilizer bushing is 1.5 to 3 times the wall thickness δ of the pressure block (see Figure 6-5 , Figure 7-5 ).

[0033] There is a protrusion 103c in the upper middle part of the stabilizer bar bushing 1c, and there is also a protrusion 203c in the middle part of the pressure block 2c, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com