Single end strip of automobile safety belt and preparation method thereof

A seat belt, single-ended technology, applied to the structure of seat belts/slings, etc., can solve problems such as affecting reliability, rising manufacturing costs, breaking and falling off, and achieve the effects of protecting car occupants, improving safety effects, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

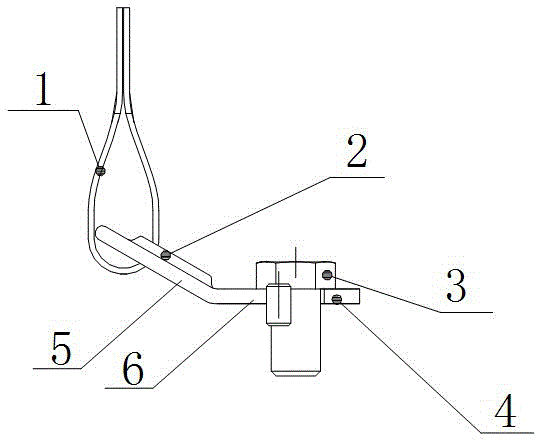

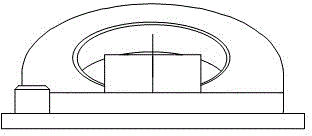

[0017] Such as figure 1 with figure 2 As shown, the single-end piece of the automobile seat belt of the present invention includes a single-end piece body 4 having a webbing connection portion 5 connected with the seat belt webbing 1, and a single-end piece body 4 fixed to The fixed connection part 6 on the vehicle body, the webbing connection part 5 is provided with an inner ring in the center, the seat belt webbing 1 passes through the inner ring to realize the connection with the single-end sheet body 4, and a flange 2 is provided along the edge of the inner ring .

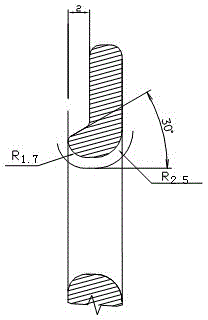

[0018] Such as image 3 , The flanging includes a circular arc surface in contact with the webbing of the seat belt, and an inclined surface located on the back side of the circular arc surface, wherein the R angle of the circular arc surface is between R1.5-3.0mm, preferably the arc surface R angle The front arc is R1.7mm, and the rear arc is R2.5mm. The angle between the inclined plane and the axis of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com