Winding disc structure of steel wire winding machine

A technology of steel wire winding machine and winding disc, which is applied in the field of winding machinery, can solve problems such as complicated installation and unloading operations, unsynchronized work, and uneven winding of steel wires, so as to ensure the quality of pipe products, improve labor productivity, and simplify the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

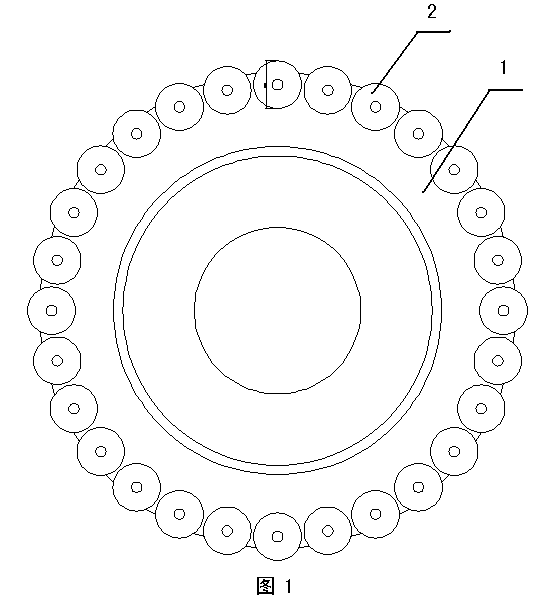

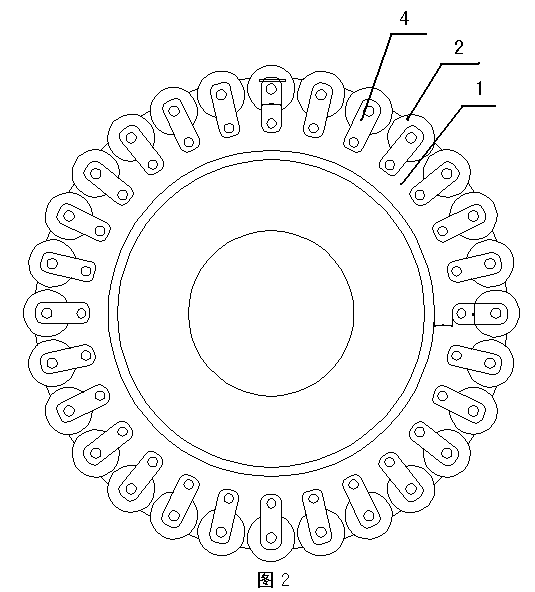

[0029] The present invention as figure 2 , Figure 4 , Figure 5 , Image 6 As shown, the winding disc structure of the steel wire winding machine is mainly composed of a winding disc and 28 sets of wire storage wheel assemblies uniformly fixed on the circumference of the winding disc.

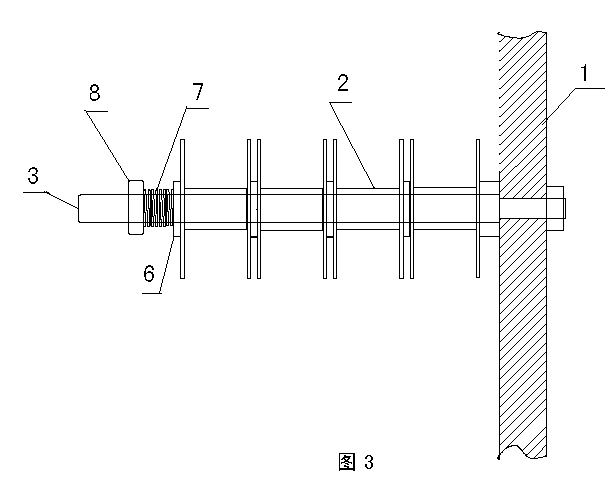

[0030] The wire storage wheel assembly mainly includes a wire storage wheel, a connecting shaft, a splint, a wire storage wheel shaft and a self-locking pin. One end of the connecting shaft is fixedly connected with the winding disc bolts, and 4 pairs of splints are equidistantly arranged at the other end of the connecting shaft. A U-shaped groove is arranged at the center of the shaft at 2 / 3 of the height of the splint, and a self-locking pin hole and a self-locking pin keyway are respectively arranged at both radial ends of the top of the splint. The two ends of the wire storage wheel shaft are provided with bosses that match the U-shaped grooves, and the outer walls of both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com