Method and device for preparing polysilicon by electromagnetically separating aluminum-silicon alloy solution

An aluminum-silicon alloy, electromagnetic separation technology, applied in the direction of silicon compounds, chemical instruments and methods, non-metallic elements, etc., can solve the problems that do not meet the value orientation of industrial production, increase the melting temperature of alloys, and slow the pulling speed of ingots. The effect of low cost, short production cycle and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

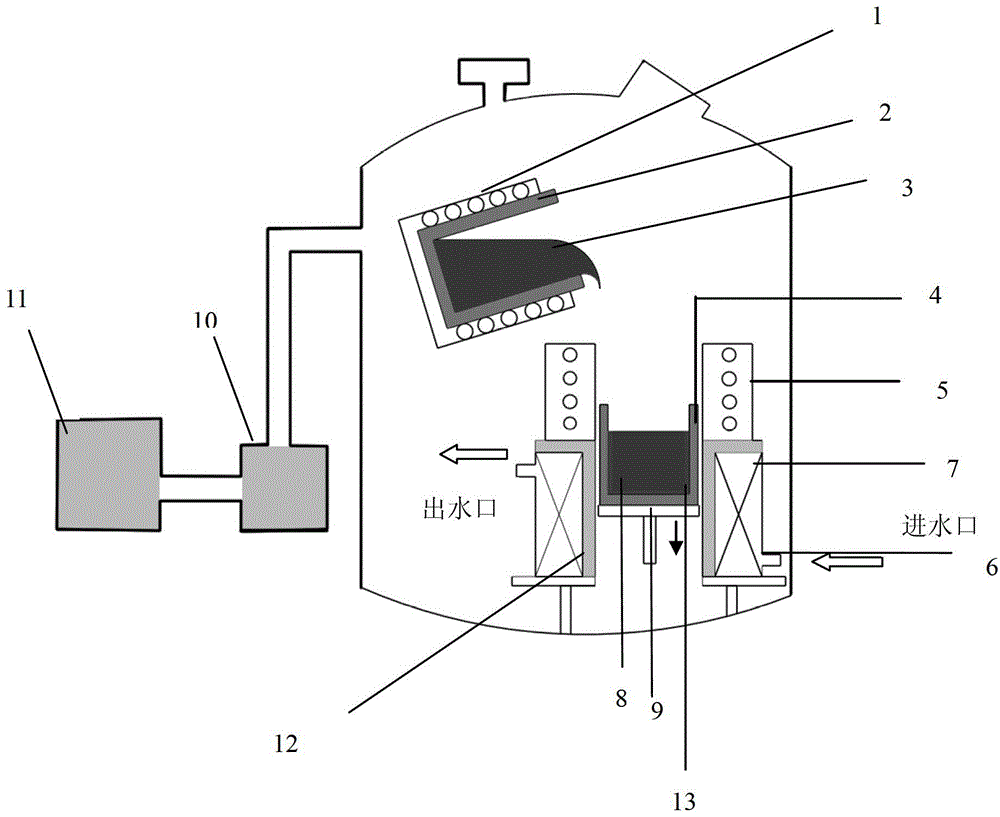

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0028] Referring to Figure 1, using 99.6% pure aluminum and 99% industrial silicon as raw materials, put the configured Al-35%wtSi alloy in an intermediate frequency induction furnace for melting, and turn on the heating furnace to make the inner diameter 120 mm, height 300 mm The temperature of the quartz ceramic crucible was slowly raised to 880°C, and the Al—35%wtSi alloy melt was kept at 900°C for 30 minutes, then poured into the quartz crucible, the heating furnace was turned off, the crucible was lowered into the magnetic field generator, and the magnetic field generator The excitation voltage is adjusted to 80V. Apply the magnetic field until the alloy is completely solidified, then turn off the magnetic field, and the time is 25min.

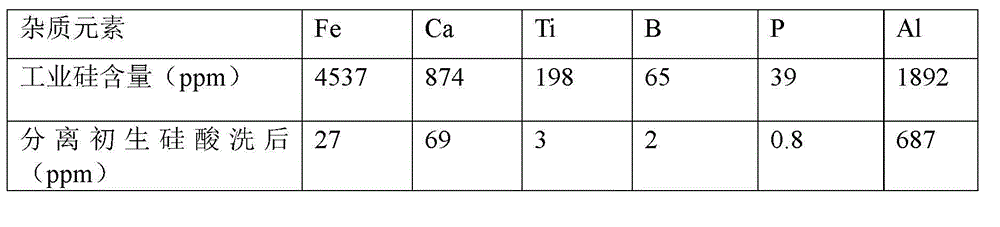

[0029] The solid silicon at the bottom and around the ingot is removed by wire cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com