A device and method for removing impurities from circulating tert-butanol in a cyclohexanone ammoximation process

A technology of cyclohexanone amidoxime and tert-butanol, which is used in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. The problems of high water content at the top of the alcohol recovery tower and the increased proportion of circulating tert-butanol water have achieved the effect of solving the difficulty of separation, avoiding a large number of side reactions, and high utilization of mass transfer space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

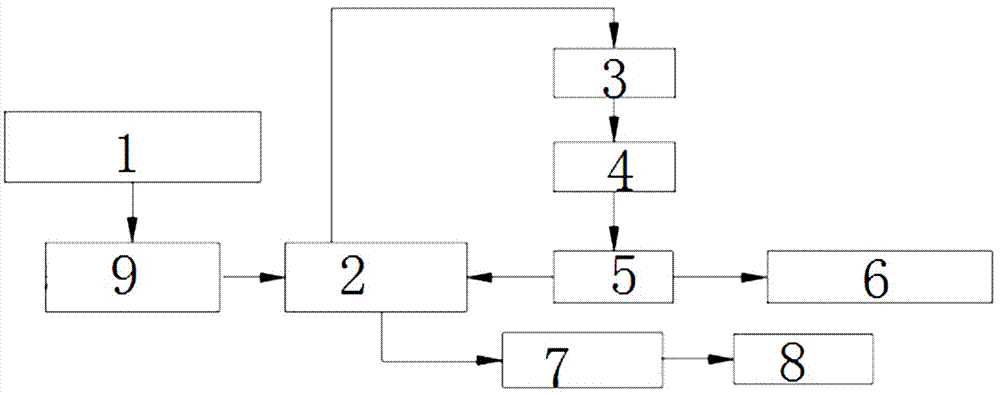

[0023] A device for removing impurities by circulating tert-butanol in a cyclohexanone ammoximation process, comprising a circulating tert-butanol storage tank 1 and a tert-butanol refining tower 2, and the top of the tert-butanol refining tower 2 is sequentially connected to a condenser 3, Reflux tank 4 and reflux pump 5, reflux pump 5 is respectively connected to tert-butanol refining tower 2 and new ring tert-butanol storage tank 6 by pipeline, and the tower bottom of described tert-butanol refining tower 2 passes through tower bottom discharge pump 7 Connect to waste water treatment unit 8.

[0024] Further, a feed pump 9 is provided between the circulating tert-butanol storage tank 1 and the tert-butanol refining tower 2 .

[0025] Further, the tert-butanol refining tower 2 adopted is a new vertical sieve tray tower.

[0026] Further, the number of trays of the tert-butanol refining tower 2 is 24 layers, the feed position connected to the circulating tert-butanol storage...

Embodiment 2

[0028] A method for removing impurities of circulating tert-butanol in a cyclohexanone ammoximation process, carried out according to the following steps:

[0029] a. The tert-butanol in the circulating tert-butanol storage tank is pumped to the tert-butanol refining tower through the feed of the tert-butanol refining tower, and the material flow rate is 2m 3 / h, the feed tray position is the 17th floor;

[0030] b. The reflux at the top of the tower is controlled at 1m 3 / h, reflux ratio 0.5, tower top temperature 80°C;

[0031] c. The steam feed rate at the bottom of the tower is 3t / h, and the temperature at the bottom of the tower is 90°C;

[0032] d. Based on the above control conditions, after analysis, the total impurities in the top tert-butanol 78%, and the bottom tert-butanol content < 0.5%.

Embodiment 3

[0034] A method for removing impurities of circulating tert-butanol in a cyclohexanone ammoximation process, carried out according to the following steps:

[0035] a. The tert-butanol in the circulating tert-butanol storage tank is pumped to the tert-butanol refining tower through the feed of the tert-butanol refining tower, and the material flow rate is 3m 3 / h, the feed tray position is the 17th floor;

[0036] b. The reflux at the top of the tower is controlled at 2m 3 / h, reflux ratio 0.67, tower top temperature 78°C;

[0037] c. The steam feed rate at the bottom of the tower is 5t / h, and the temperature at the bottom of the tower is 95°C;

[0038] d. Based on the above control conditions, after analysis, the total impurities in the top tert-butanol 80%, and the bottom tert-butanol content<0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com