High-peel strength and anti-hydrolysis wet polyurethane resin and preparation method thereof

A polyurethane resin and hydrolysis-resistant technology, applied in the field of thermoplastic polyurethane resin for synthetic leather and its preparation, can solve problems such as peel strength and hydrolysis resistance gap, and achieve the effects of high peel strength, improved peel strength, and enhanced compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

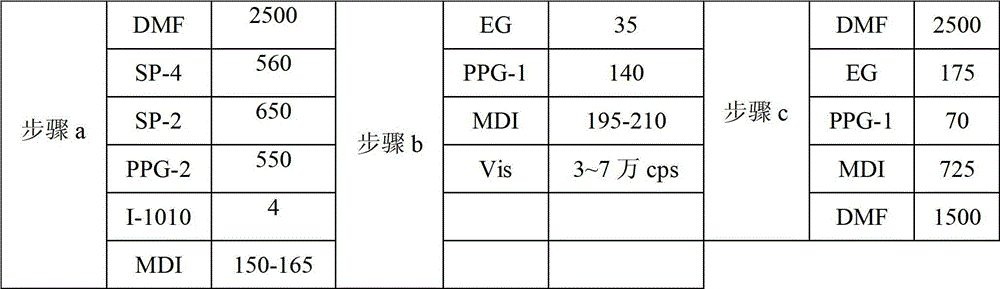

Embodiment 1

[0044] a. Add 10-20% isocyanate, 80-90% polyol compound and antioxidant to DMF and react at 75-85℃ for 1-2h, and the solid content of the reaction liquid is controlled at 40-50%; -NCO / - The molar ratio of OH is 0.8-0.9:1;

[0045] b. Add 5-15% of polyol compound and 15-30% of diol chain extender to the reaction solution, add 15-20% of isocyanate for prepolymerization, and add 0.1-0.5kg of organic bismuth catalyst Prepolymer is obtained by reacting at 75-85℃ for 1-3h in the presence of presence. DMF is added during the reaction to adjust the solid content of the prepolymer at 45-60% and the viscosity at 30,000-70000cps / 75℃;

[0046] c. Add the remaining polyol compound, the remaining glycol chain extender and the remaining isocyanate to the prepolymer, and after stirring uniformly, continue the reaction at 75-85°C for 2-5 hours, depending on the degree of reaction during the reaction Add DMF dilution to the system in two to three steps to control the viscosity of the system to incr...

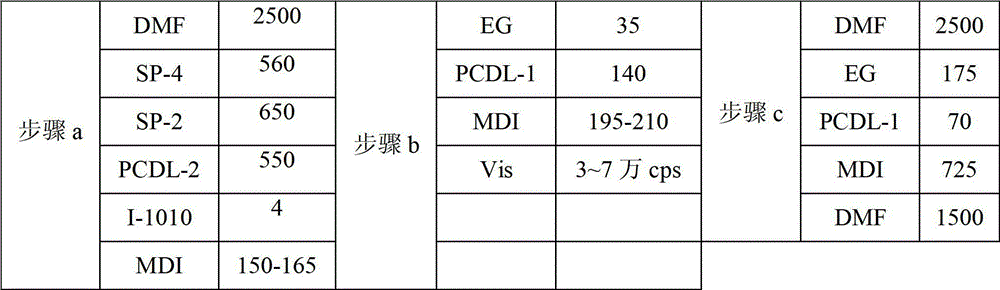

Embodiment 2

[0051] The preparation method of this embodiment is the same as that of embodiment 1. The raw materials used in each step and the addition amount are as follows:

[0052]

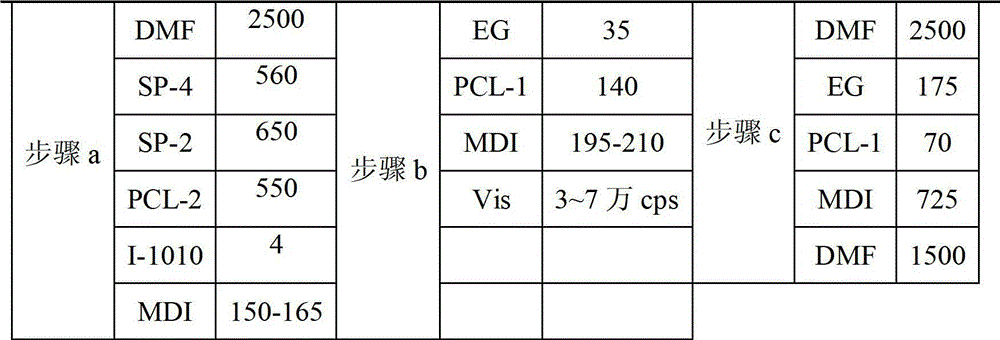

Embodiment 3

[0054] The preparation method of this embodiment is the same as that of embodiment 1. The raw materials used in each step and the addition amount are as follows:

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com