A lead-carbon battery negative plate containing lead-graphene composite material

A composite material and lead-carbon battery technology, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problem of uneven mixing of lead and carbon, achieve increased contact interface, broad application prospects, and inhibit sulfation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

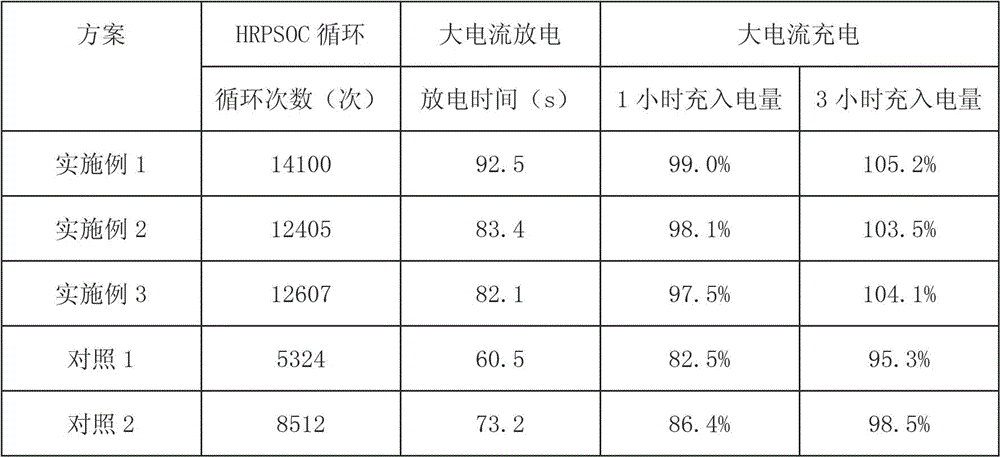

Examples

Embodiment 1

[0016] (1) Ultrasonic dispersion of graphite oxide flakes in magnesium nitrate isopropanol solution, the weight ratio of graphite oxide flakes to magnesium nitrate is 100:1, to prepare positively charged graphite oxide flake sol.

[0017] (2), with the graphite oxide flake sol of step (1) as electrolyte, the graphite oxide flake thin film is electrophoretically deposited on the pure lead plate, the deposition voltage is set as 100V, after deposition 5min, the lead plate carrying the graphite oxide flake is taken out, Dry under vacuum at 50°C for 4 h.

[0018] (3), the lead plate that the graphite oxide sheet of step (2) is loaded is reduced 2h in 60 ℃ of saturated hydrazine hydrate atmospheres, obtains graphene thin film, and each graphene sheet comprises 10-20 carbon atom layers;

[0019] (4), plating solution adopts fluoroboric acid plating solution, and plating solution is to prepare lead plating solution as raw material with 200g / L lead fluoroborate, 220g / L fluoroboric aci...

Embodiment 2

[0025] (1) Ultrasonic dispersion of graphite oxide flakes in magnesium nitrate isopropanol solution, the weight ratio of graphite oxide flakes to magnesium nitrate is 100:1, to prepare positively charged graphite oxide flake sol.

[0026] (2), with the graphite oxide flake sol of step (1) as electrolyte, the graphite oxide flake thin film is electrophoretically deposited on the pure lead plate, the deposition voltage is set as 100V, after deposition 5min, the lead plate carrying the graphite oxide flake is taken out, Dry under vacuum at 50°C for 4 h.

[0027] (3), the lead plate that the graphite oxide sheet of step (2) is loaded is reduced 2h in 60 ℃ of saturated hydrazine hydrate atmospheres, obtains graphene thin film, and each graphene sheet comprises 10-20 carbon atom layers;

[0028] (4), plating solution adopts fluoroboric acid plating solution, and plating solution is to prepare lead plating solution as raw material with 200g / L lead fluoroborate, 220g / L fluoroboric aci...

Embodiment 3

[0034] (1) Ultrasonic dispersion of graphite oxide flakes in magnesium nitrate isopropanol solution, the weight ratio of graphite oxide flakes to magnesium nitrate is 100:1, to prepare positively charged graphite oxide flake sol.

[0035](2), with the graphite oxide flake sol of step (1) as electrolyte, the graphite oxide flake thin film is electrophoretically deposited on the pure lead plate, the deposition voltage is set as 100V, after deposition 5min, the lead plate carrying the graphite oxide flake is taken out, Dry under vacuum at 50°C for 4 h.

[0036] (3), the lead plate that the graphite oxide sheet of step (2) is loaded is reduced 2h in 60 ℃ of saturated hydrazine hydrate atmospheres, obtains graphene thin film, and each graphene sheet comprises 10-20 carbon atom layers;

[0037] (4), plating solution adopts fluoroboric acid plating solution, and plating solution is to prepare lead plating solution as raw material with 200g / L lead fluoroborate, 220g / L fluoroboric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com