Production process improvement method of flexible printed circuit board containing welding finger

A flexible circuit board and manufacturing process technology, which is applied in the direction of the electrical connection of printed components, can solve the problems of poor soldering finger pad misalignment, ineffective control of soldering fingers, and poor quality of semi-circular arc holes, etc., to achieve the solution of semi-circular arc The effect of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

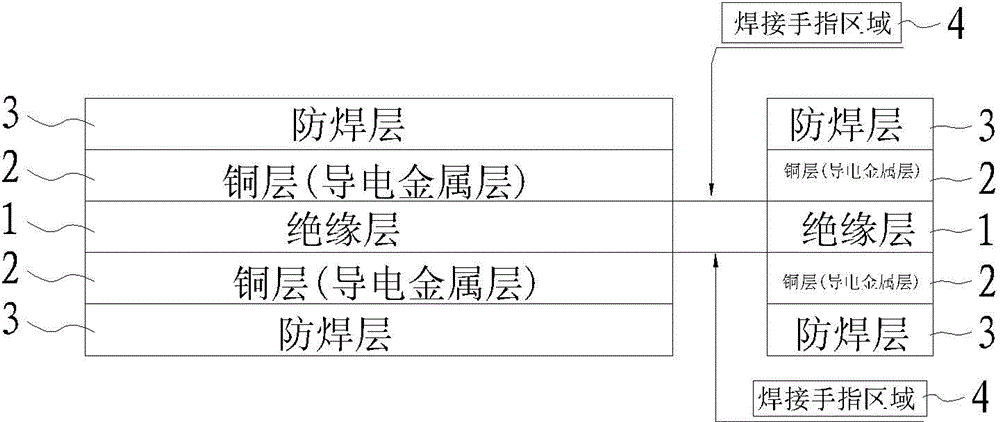

[0021] refer to figure 1 Shown is a structure of a flexible circuit board with soldering fingers, a conductive metal layer 2 is formed on a flexible insulating substrate 1; generally, the conductive metal layer 2 is also covered with a layer of solder resist layer 3 , in order to protect the conductive metal layer 2 from being damaged during welding, the welding finger area 4 is provided with finger pads and drilled to achieve.

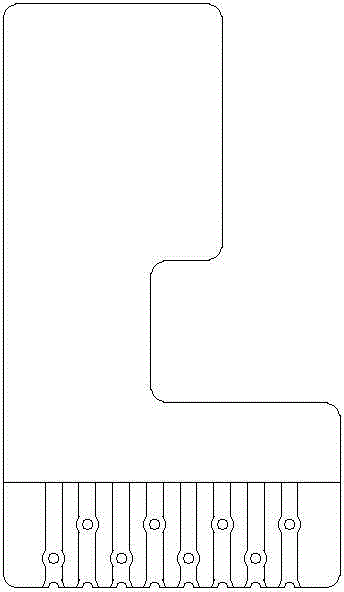

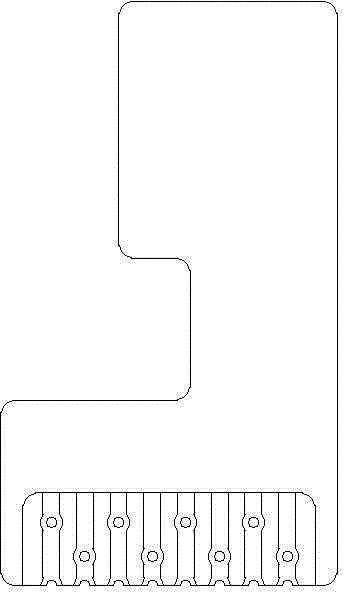

[0022] Figure 2a and Figure 2b Shown are the front and back sides of the flex circuit board with soldered fingers, respectively. It can be seen from the figure that each finger pad on the double-layer FPC has two metallized holes (PTH), one of which is a full circle hole located in the middle of the finger pad, and the other is located at the end of the finger pad The semi-arc climbing tin hole. Qualified flexible cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com