Passenger conveyor

A technology for passenger conveying equipment and frames, which can be used in transportation and packaging, escalators, etc., and can solve problems such as difficulty in dismantling operations, deformation of upper and lower chord materials, and difficulty in correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below with reference to the drawings. In each drawing, the same reference numerals are used for the same or similar components, and the same descriptions are omitted.

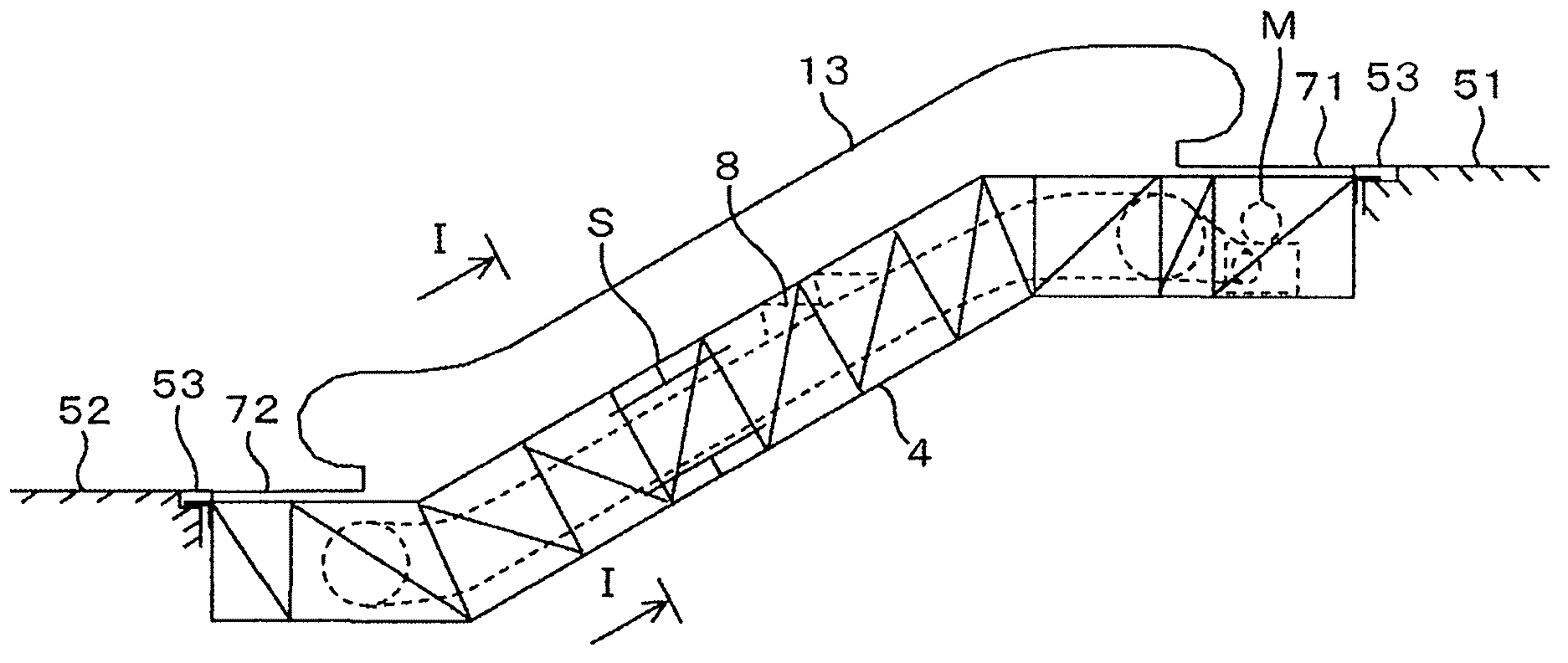

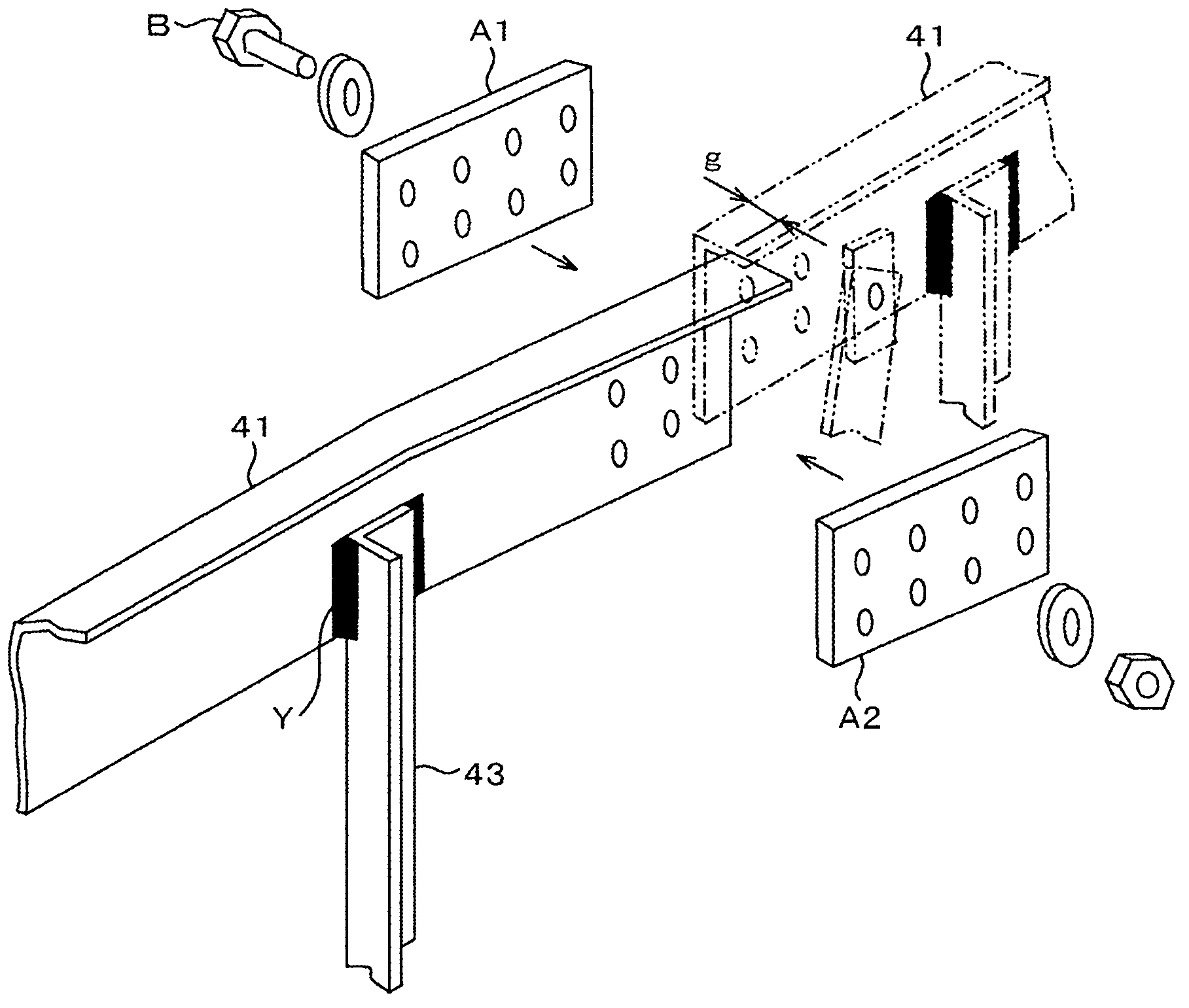

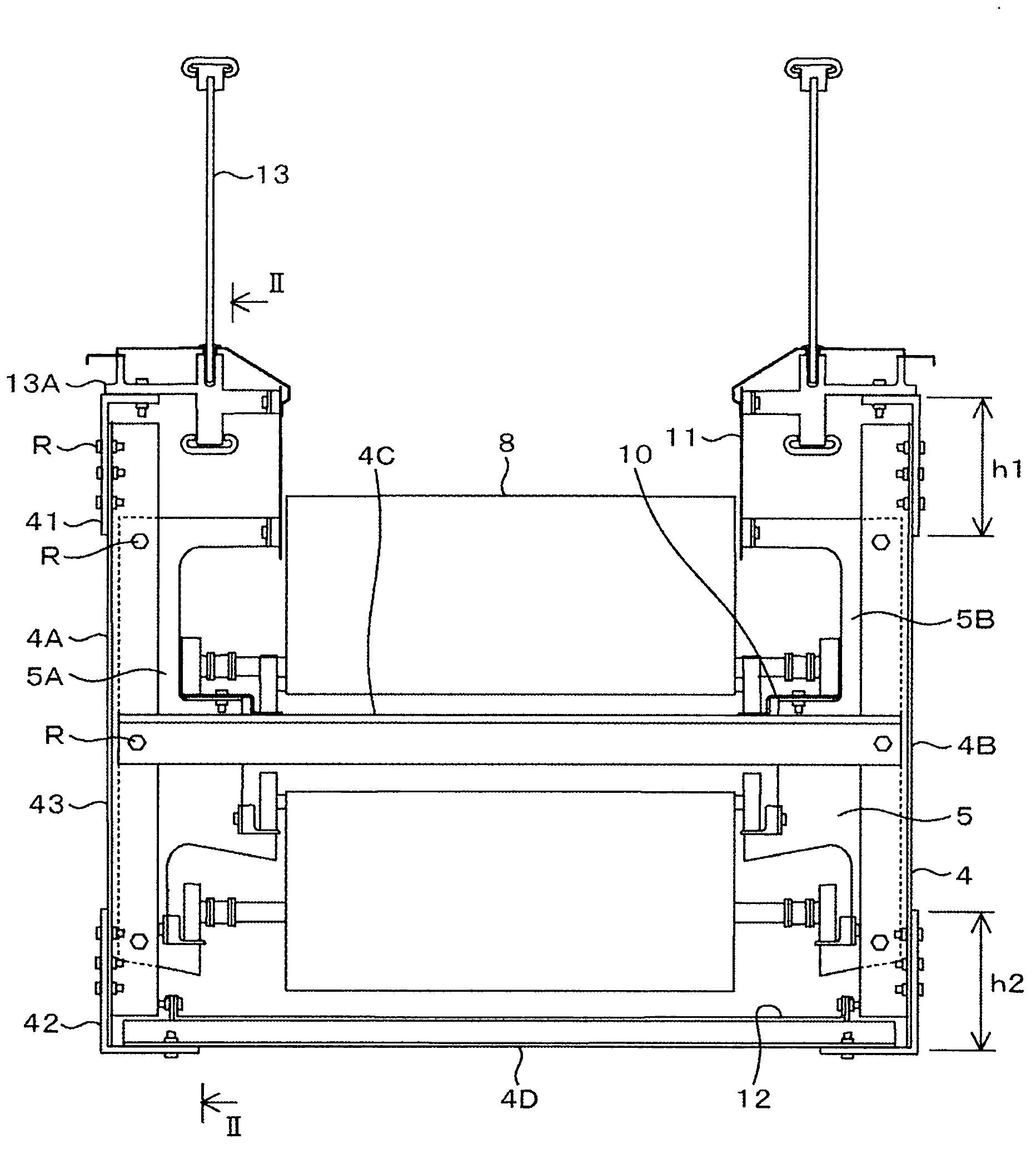

[0024] Refer to the following Figure 1 to Figure 4 An escalator, which is one type of passenger conveyance facilities as an embodiment of the present invention, will be described.

[0025] figure 1 It is an overall side view of the passenger conveyor of the present invention. The escalator in this embodiment is as figure 1 As shown, there is a frame body 4 installed on the building structure, and entrance and exit floors 71 and 72 provided at both ends of the length direction of the frame body 4 are annularly connected and between these entrance and exit floors 71 and 72 The steps 8 that circulate, the driving device M for driving the steps 8 , and the handrails 13 that face each other in the left and right directions along the rotation direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com