Multifunctional dust collection device for concrete mixing plant and bin

A technology of dust collecting device and mixing station, which is applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as the limitation of safety valve efficacy, and achieve the effect of complete functions, better dust removal effect and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

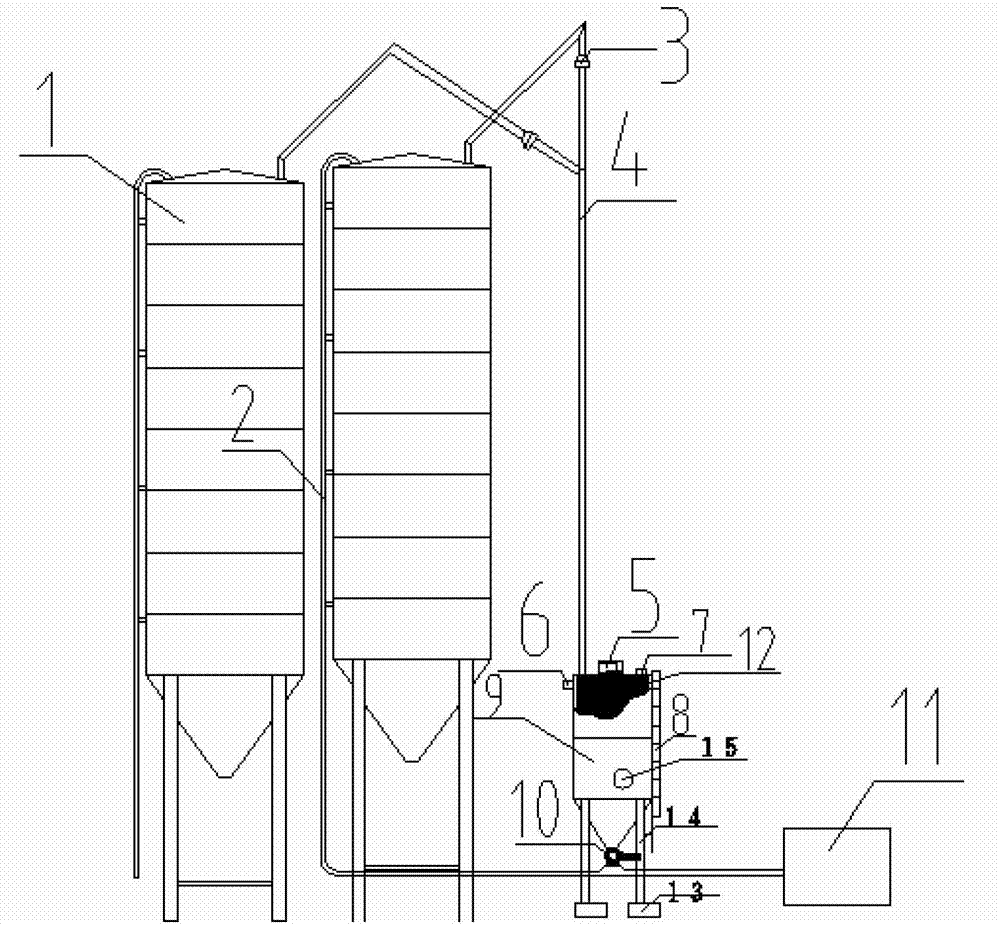

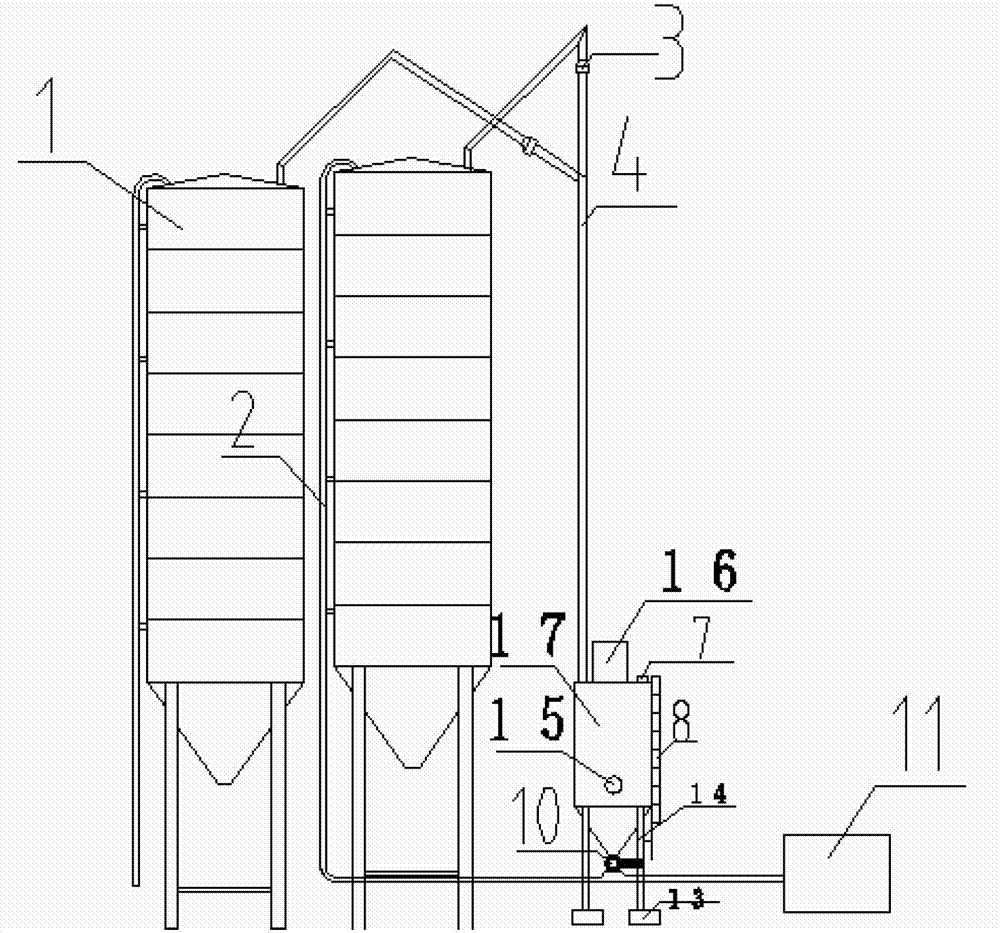

[0017] Figure 1-2 Middle: powder storage bin 1 (dust generation source, single or multiple bins, or mixing station), powder conveying pipeline 2: (can be single or multiple pipelines); one-way valve 3; Dust pipeline 4; exhaust system (composed of exhaust motor, fan and pipeline, etc.) 5; vibrator or / and pulse blowing valve (can be used alone or at the same time) 6; pressure relief valve 7; collection bin walkway or ladder 8, Dust collection and dust removal integrated bin 9 (or separate dust collection bin and dust collector); powder material transmission check system 10; gas source 11 (gas generation source, such as air compressor, blower, blower, bulk cement truck, etc. have similar effects device); dust filter device (such as filter bag, filter element or other similar function) 12; sensor 13 (used to measure the weight of 9); powder material collection bin leg 14; material level gauge 15 (to measure the material in 9 Volume height); dust collector 16 (the dust removal eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com