Die for manufacturing blades with multiple sizes for wind driven generator

A fan blade and multi-size technology is applied in the field of molds that can prepare a variety of wind turbine blades, which can solve the problems of single production product, inconvenient transportation, and inability to upgrade, and achieves easy transportation, high reuse rate, and reduced transportation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

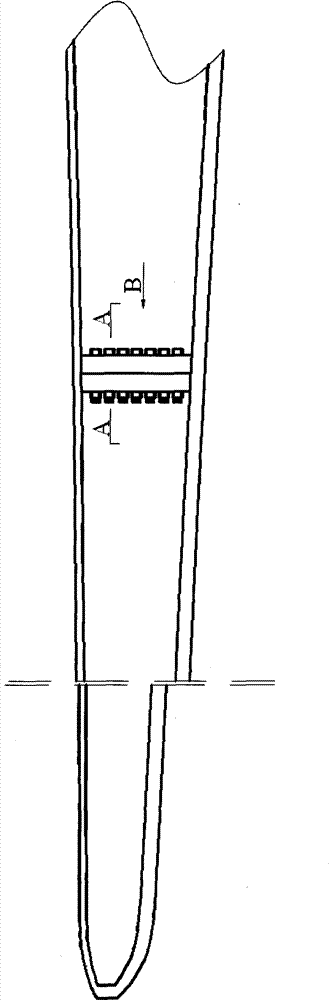

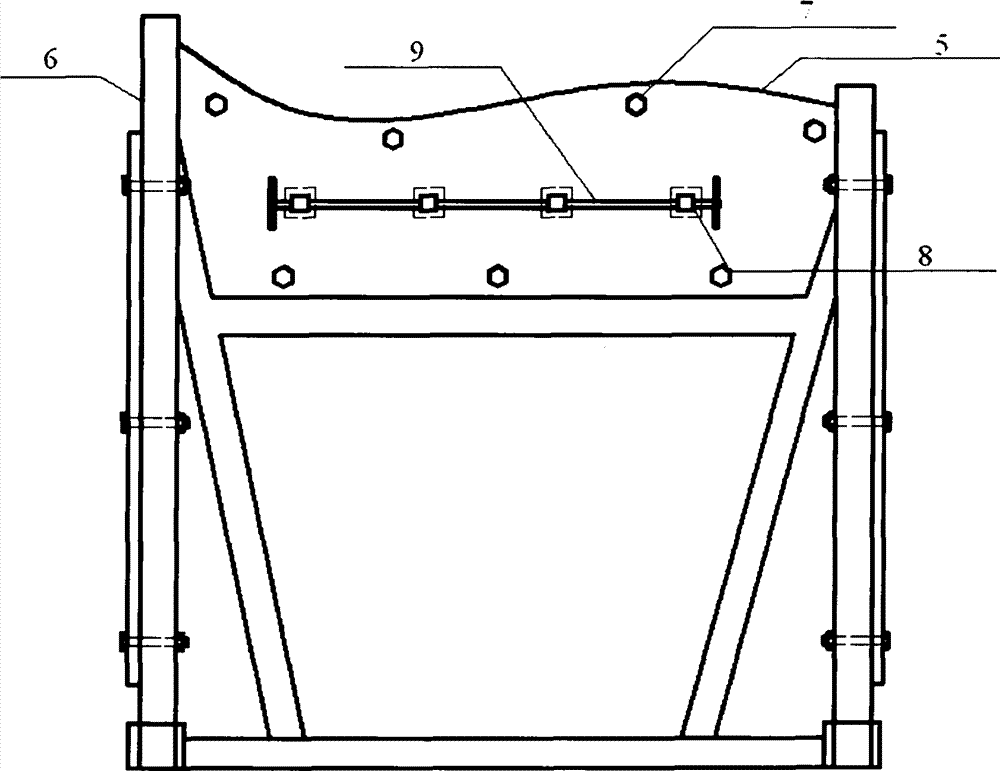

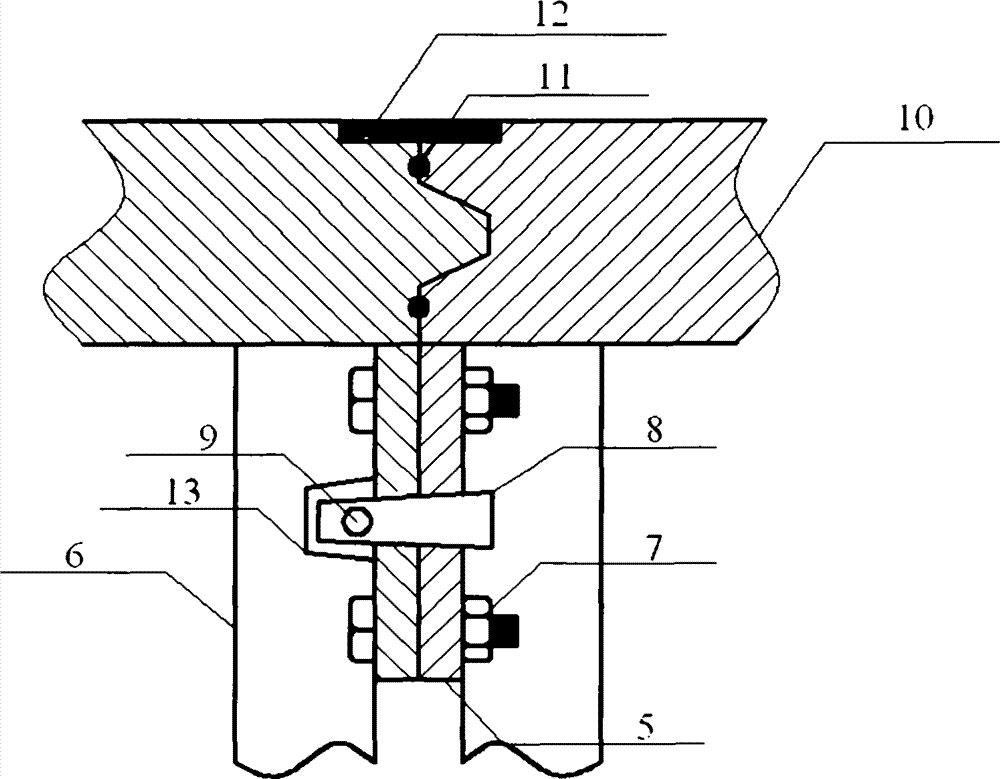

[0018] like Figure 4 As shown, the entire set of molds is divided into multiple sections. When it is necessary to make blades of a certain size, a certain section or several sections of molds must be changed to meet the blade size requirements. A single section of the mold can be reused in the production of multi-size blades. Among them, the blade root is divided into several models according to the size of the connecting hub, which correspond to the size of the corresponding hub connecting flange. The size hardly affects the aerodynamic shape of the blade, and the blade tip has little influence on the aerodynamic shape. The length of the blade is mainly completed by changing the blade tip. The root connection of blades with the same power and different sizes is basically the same, so the same type of blade root and blade middle front end mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com