Automatic lifting and feeding mechanism, and method

An automatic lifting and feeding mechanism technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of affecting production efficiency, impreciseness, high operation intensity, etc., to overcome operation intensity and production cost, control action precision, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

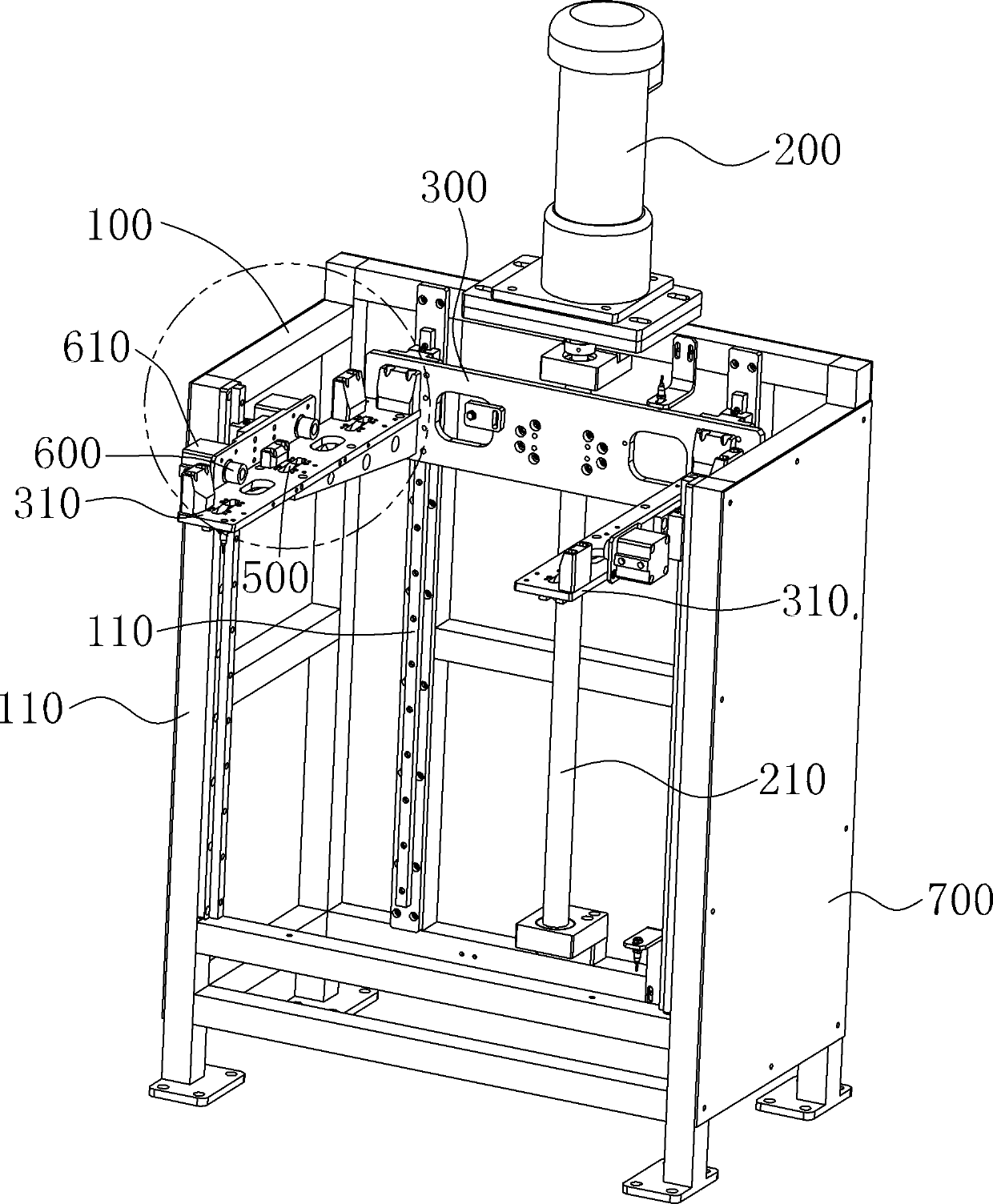

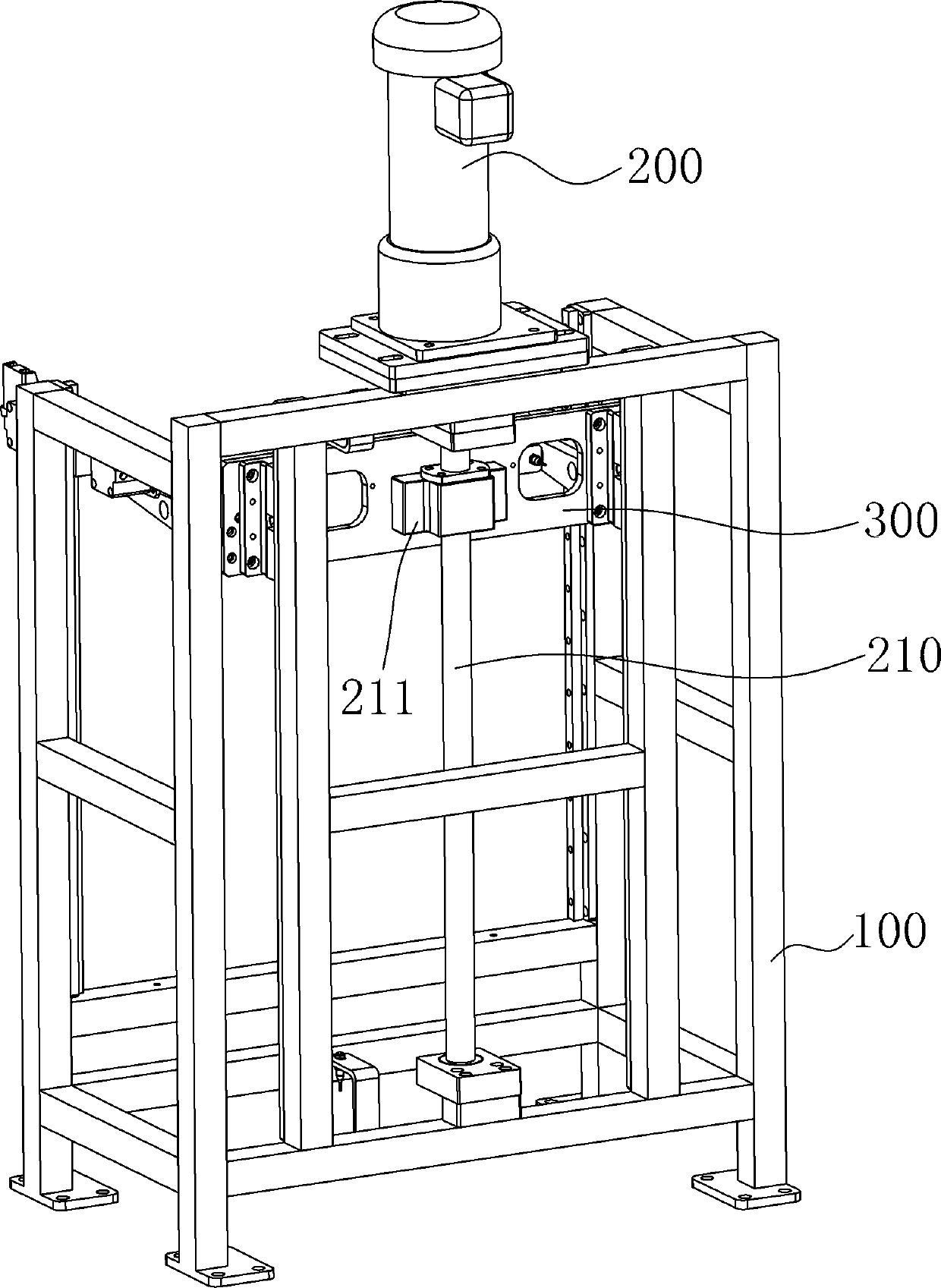

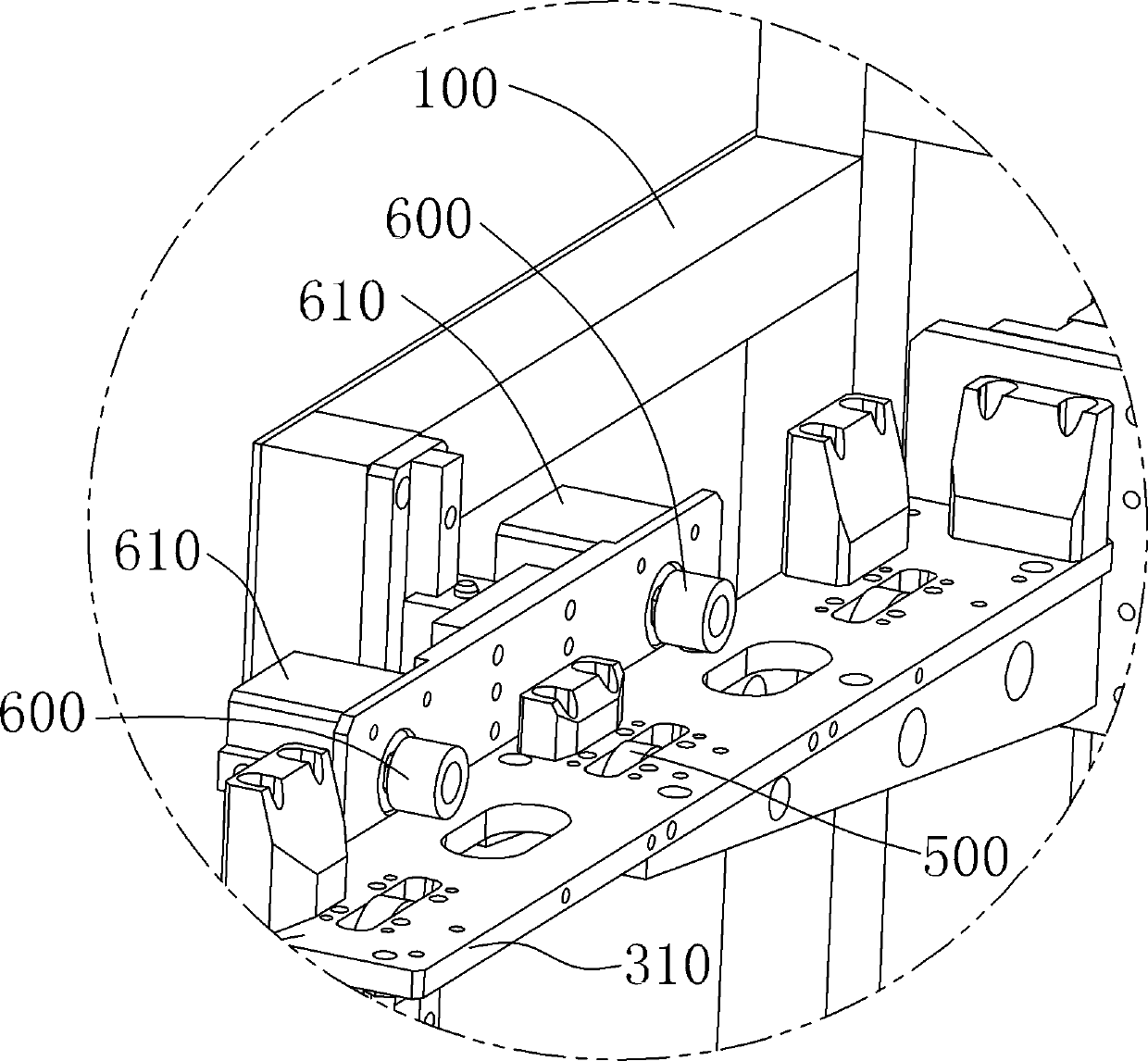

[0033] see figure 1 , figure 2 and image 3 As shown, the automatic lifting and feeding mechanism of the present invention, in a preferred embodiment, includes:

[0034] Mechanism support 100, guide rails 110 are evenly arranged on its side, the number of the guide rails 110 can be set to two or four according to the weight of the article, and the guide rails 110 play a guiding role;

[0035] Lifting device, it comprises motor 200 and the screw mandrel 210 that is connected with this motor 200, and this screw mandrel 210 is connected with this motor 200 by coupling, and makes this screw mandrel 210 rotate by the effect of this motor 200, and this screw mandrel 210 The outer sleeve is provided with a screw nut 211;

[0036] The supporting platform 300, one end of which is movably sleeved on the above-mentioned screw mandrel 210 through the screw mandrel nut 211, when the screw mandrel 210 rotates, the supporting platform 300 and the above-mentioned screw mandrel nut 211 mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com