Irregular nut matched with foundation bolt for reducer and reducer fixing method

A technology of anchor bolts and special-shaped nuts, which is applied to nuts, threaded fasteners, engine frames, etc., can solve problems such as infirmity, hidden dangers of equipment personal safety, and loose anchor steel plates of reducers, so as to ensure equipment safety and The effect of personal safety, reasonable structure design and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

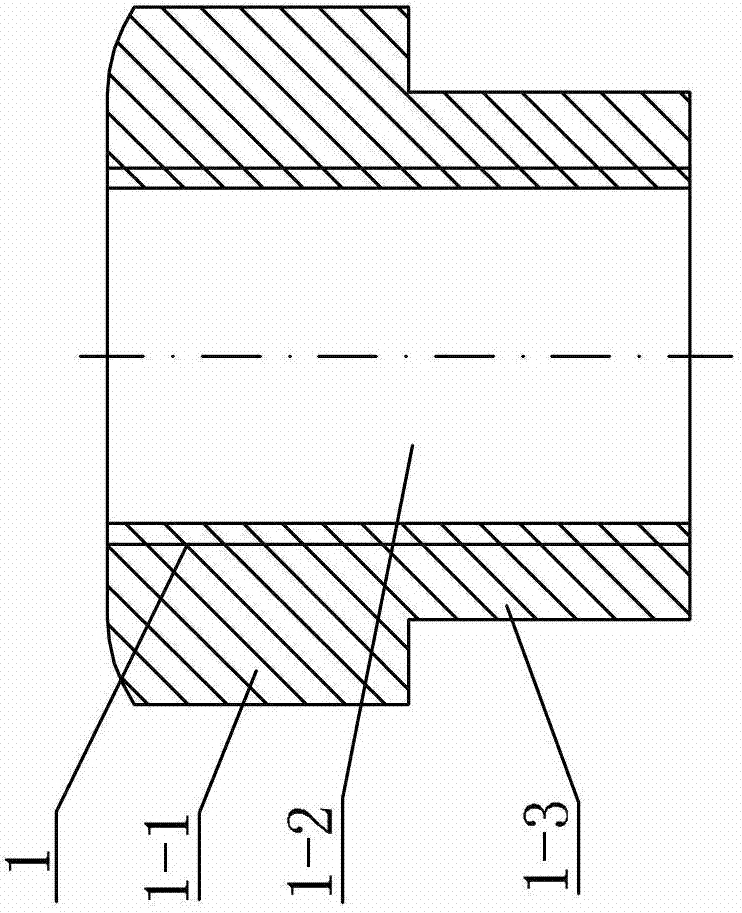

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment, the special-shaped nut 1 that a kind of reducer of this embodiment is used for supporting anchor bolt is made up of upper body 1-1 and lower body 1-3 that are made integrally, and upper body 1-1 is a prism, The lower body 1-3 is a cylinder, the upper body 1-1 and the lower body 1-3 are coaxially arranged with a stepped surface between them, and the outer diameter of the lower body 1-3 is smaller than the circumscribed circle of the upper body 1-1 The diameter of the special-shaped nut 1 is processed with an internal thread through hole 1-2 in the axial direction.

[0013] The anchor bolts in this embodiment can be M40, and the upper body in this embodiment can be a regular prism.

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 To describe this embodiment, the upper body 1-1 described in this embodiment is a quadrangular prism or a hexagonal prism. Such an arrangement can meet the needs of screwing the upper body, and is easy to operate and use. The upper body in this embodiment can be a regular square prism or a regular hexagonal prism. Others are the same as in the first embodiment.

specific Embodiment approach 3

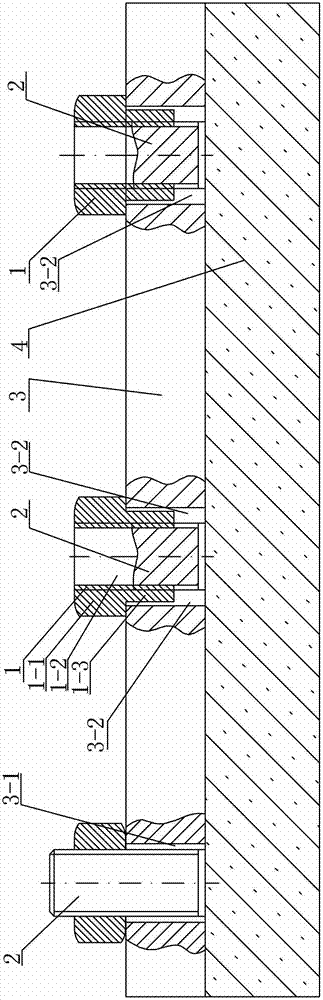

[0015] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the specific steps of a method for fixing a reducer after the anchor bolts for a reducer of this embodiment are broken are as follows:

[0016] Step 1, expanding the diameter of the through hole 3-1 on the anchor steel plate 3 corresponding to the broken anchor bolt 2;

[0017] Step 2, make special-shaped nut 1 according to the diameter of the broken anchor bolt 2 and the diameter of the through hole 3-2 on the expanded anchor steel plate 3, the outer surface of the lower body 1-3 of the special-shaped nut 1 and the anchor steel plate The inner surface of the through hole 3-2 on the 3 is clearance fit;

[0018] Step 3: Screw the lower body 1-3 and the upper body 1-1 of the prepared special-shaped nut 1 on the anchor bolt 2 in turn, press the upper body 1-1 on the anchor steel plate 3, and press the anchor steel plate 3 Tighten, and the reducer is fixed.

[0019] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com