Method dedicated for measuring chamfer of male connection end for oil casing and oil tube

A technology for external threaded joints and oil casings, applied in the direction of angle/taper measurement, etc., which can solve difficult measurement, narrow and short cones, and inability to determine whether the chamfer α size of the ends of oil casing and oil pipe male threaded joints is qualified, etc. problems, to achieve the effect of improving measurement efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

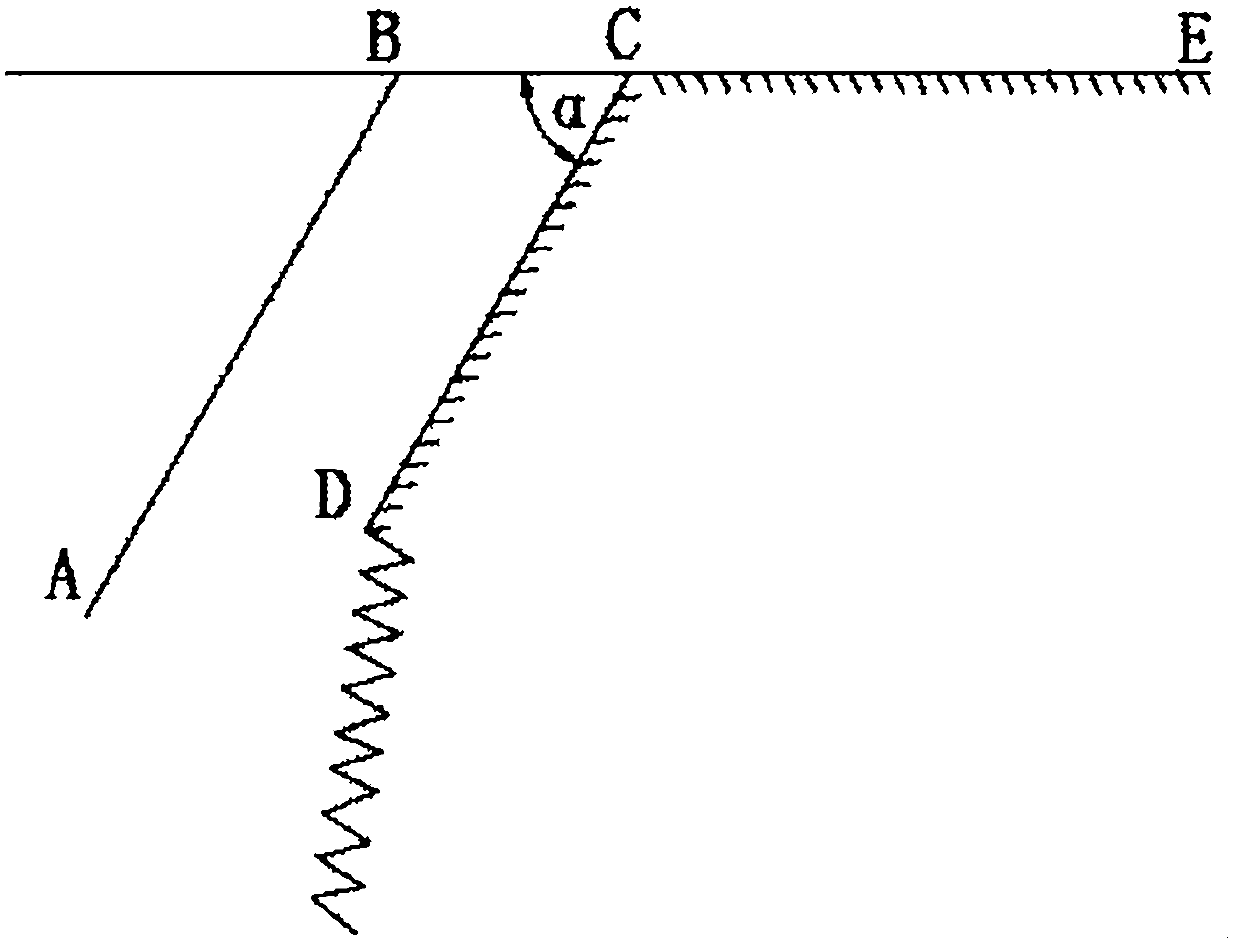

[0023] The embodiment of the present invention provides a special method for measuring the chamfering at the end of the external threaded joint of oil casing and oil pipe. The measuring method principle that the embodiment of the present invention provides:

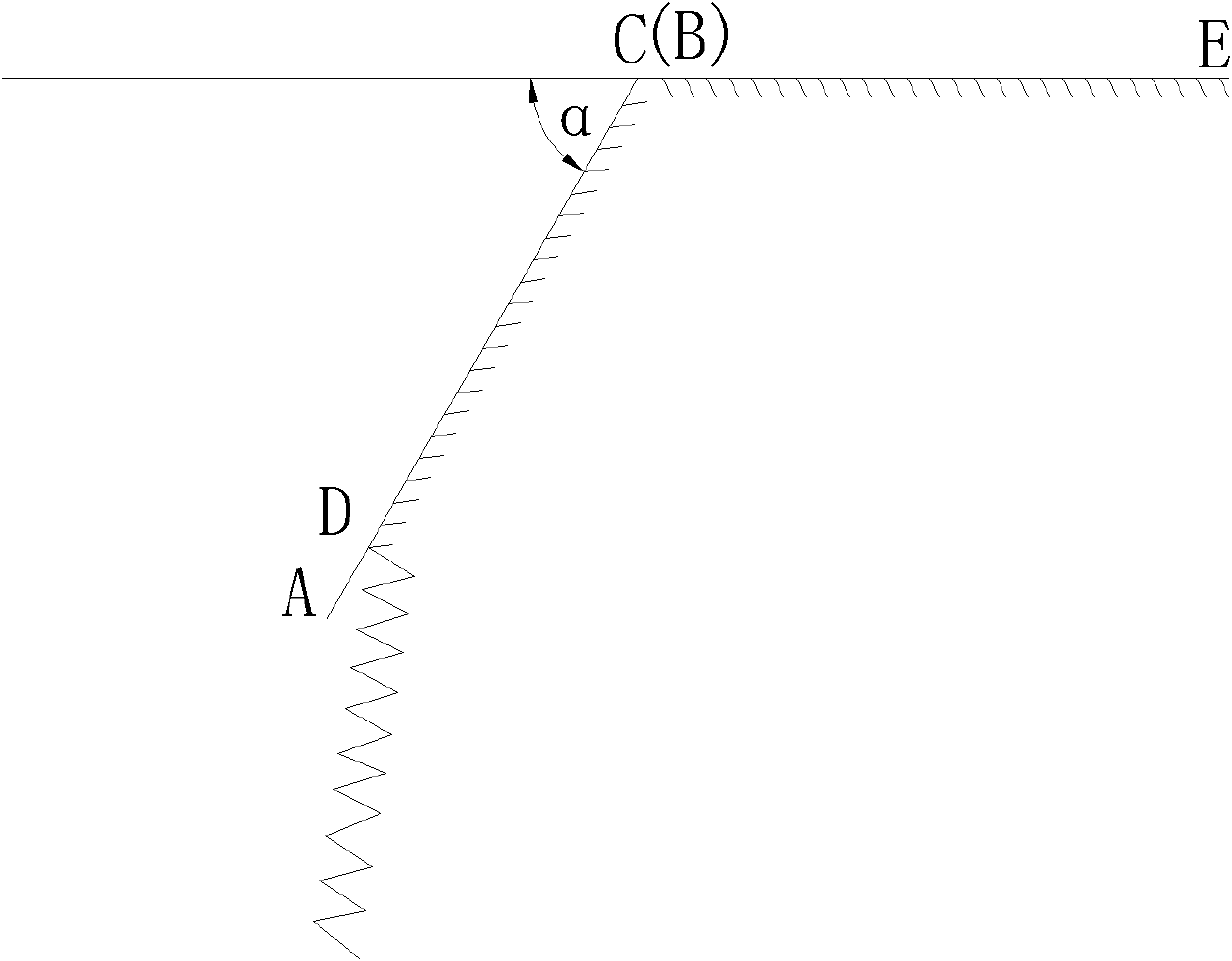

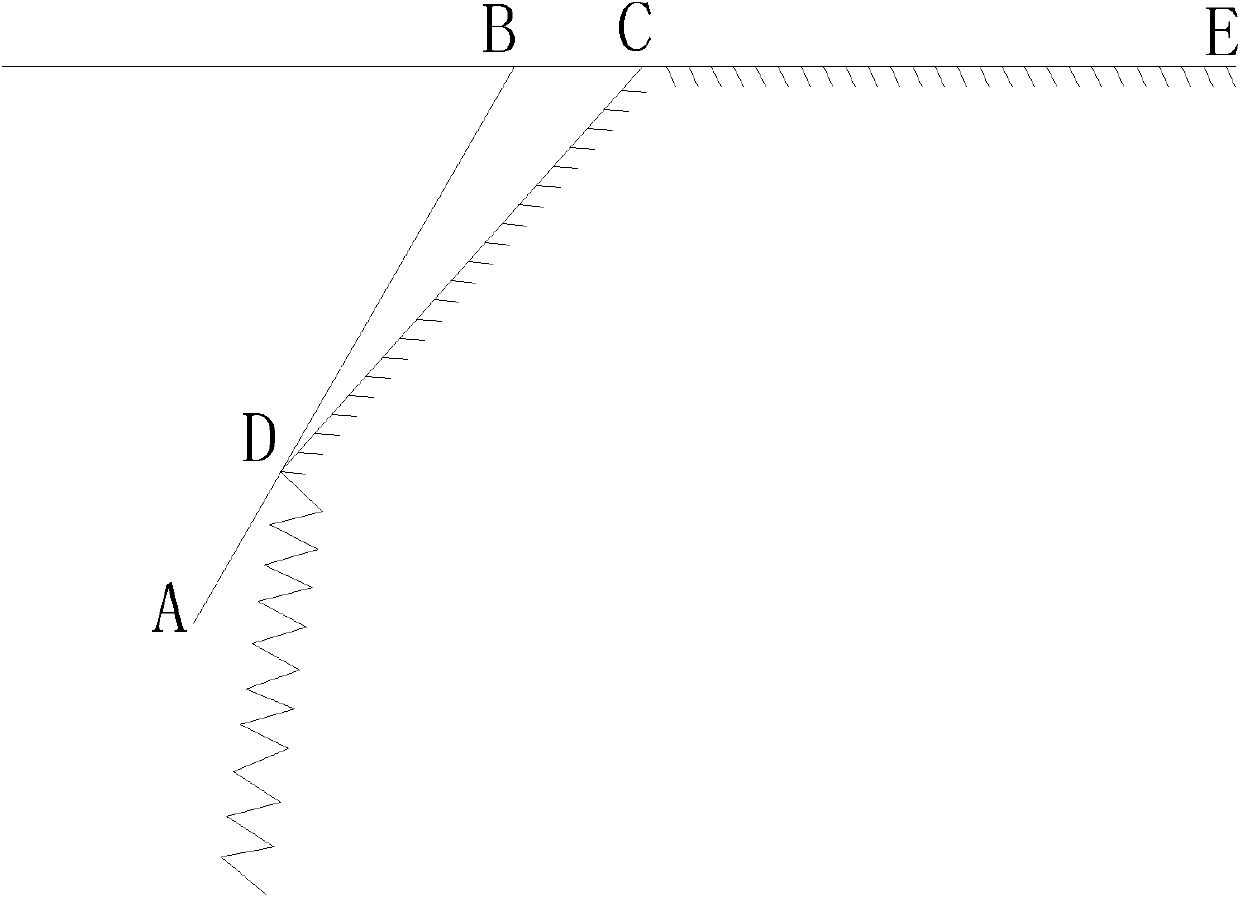

[0024] α is the end chamfer of oil casing and oil pipe external thread joint, CE is the straight line obtained by the plane truncated end surface passing through the thread axis, CD is the generatrix obtained by the plane truncated cone passing through the thread axis, BCE is obtained by the plane sectional end surface passed through the thread axis A straight line is also the baseline for measurement. ∠ABE is the supplementary angle of the standard angle of chamfering at the end of tubing or casing required by the corresponding standard. In the actual measurement process, AB moves along BE to CD, and encounters such as figure 2 , image 3 , Figure 4 situation shown. Thereby, it can be judged whether the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com