Flexible thermoelectric conversion system and manufacturing method thereof

A technology of thermoelectric conversion and manufacturing method, which is applied in the direction of thermoelectric device parts, electrical components, generators/motors, etc., can solve the problems of inability to use pipelines, etc., and achieve the effects of increasing application range, simple process steps, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

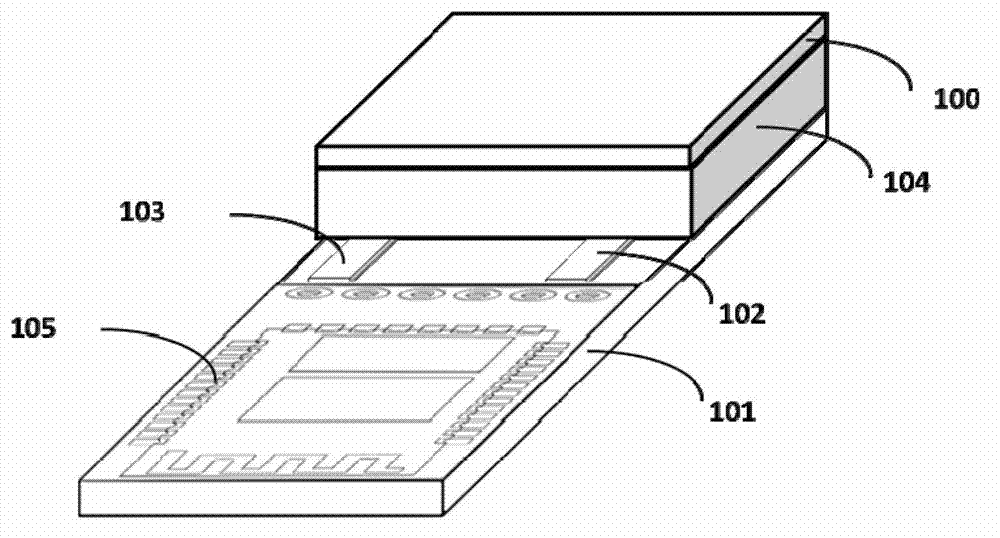

[0046] Such as image 3 with Figure 7 Shown: is a schematic structural diagram of a flexible thermoelectric conversion system. In this embodiment, the flexible thermoelectric conversion system includes a first flexible power generation generator 10 and a flexible conversion circuit for converting and outputting electrical energy from the first flexible thermoelectric generator 10, where The first flexible thermoelectric generator 10 includes a first flexible substrate 100 and a second flexible substrate 101 located under the first flexible substrate 100, and the first flexible substrate 100 and the second flexible substrate 101 are arranged between A number of alternately distributed N-type thermoelectric material particles 301 and P-type thermoelectric material particles 302, the N-type thermoelectric material particles 301 passing through the first conductive connection layer 201 and the second flexible substrate on the first flexible substrate 100 The second conductive conne...

Embodiment 2

[0064] Such as Figure 8 Shown: the schematic diagram of the structure of the flexible thermoelectric conversion system of this embodiment, Picture 9 This embodiment is a schematic structural diagram of the second flexible thermoelectric generator 20 included in the flexible thermoelectric conversion system. In this embodiment, in order to achieve good heat conduction with the outside, the first flexible substrate 100 of the second flexible thermoelectric generator 20 A through hole 401 penetrating through the first flexible substrate 100 is provided, and the through hole 401 is located directly above the N-type thermoelectric material particle 301 or the P-type thermoelectric material particle 302. At the same time, the through hole 401 can also be At the same time, it is located directly above the N-type thermoelectric material particles 301 and the P-type thermoelectric material particles 302.

[0065] Further, the second flexible substrate 101 may also be provided with a thro...

Embodiment 3

[0068] Such as Picture 10 Shown: the schematic diagram of the structure of the flexible thermoelectric conversion system of this embodiment, Picture 11 It is a schematic diagram of the structure of the third flexible thermoelectric generator 30 included in the flexible thermoelectric conversion system in the embodiment of the present invention. In this embodiment, the third flexible thermoelectric generator 30 is in the first flexible substrate 100 and the second flexible substrate. A through hole 401 is provided on the first flexible substrate 100 at the same time. The through hole 401 on the first flexible substrate 100 is located directly above the N-type thermoelectric material particles 301 and / or the P-type thermoelectric material particles 302; on the second flexible substrate 101 The through holes 401 are located directly below the N-type thermoelectric material particles 301 and / or the P-type thermoelectric material particles 302. Then, the through hole 401 is filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com