Elastic film sound production medium motor-driven panel loudspeaker

A flat-panel speaker, elastic film technology, applied in the direction of sensors, electrical components, etc., to achieve the effect of power reduction, volume reduction, and good transient response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

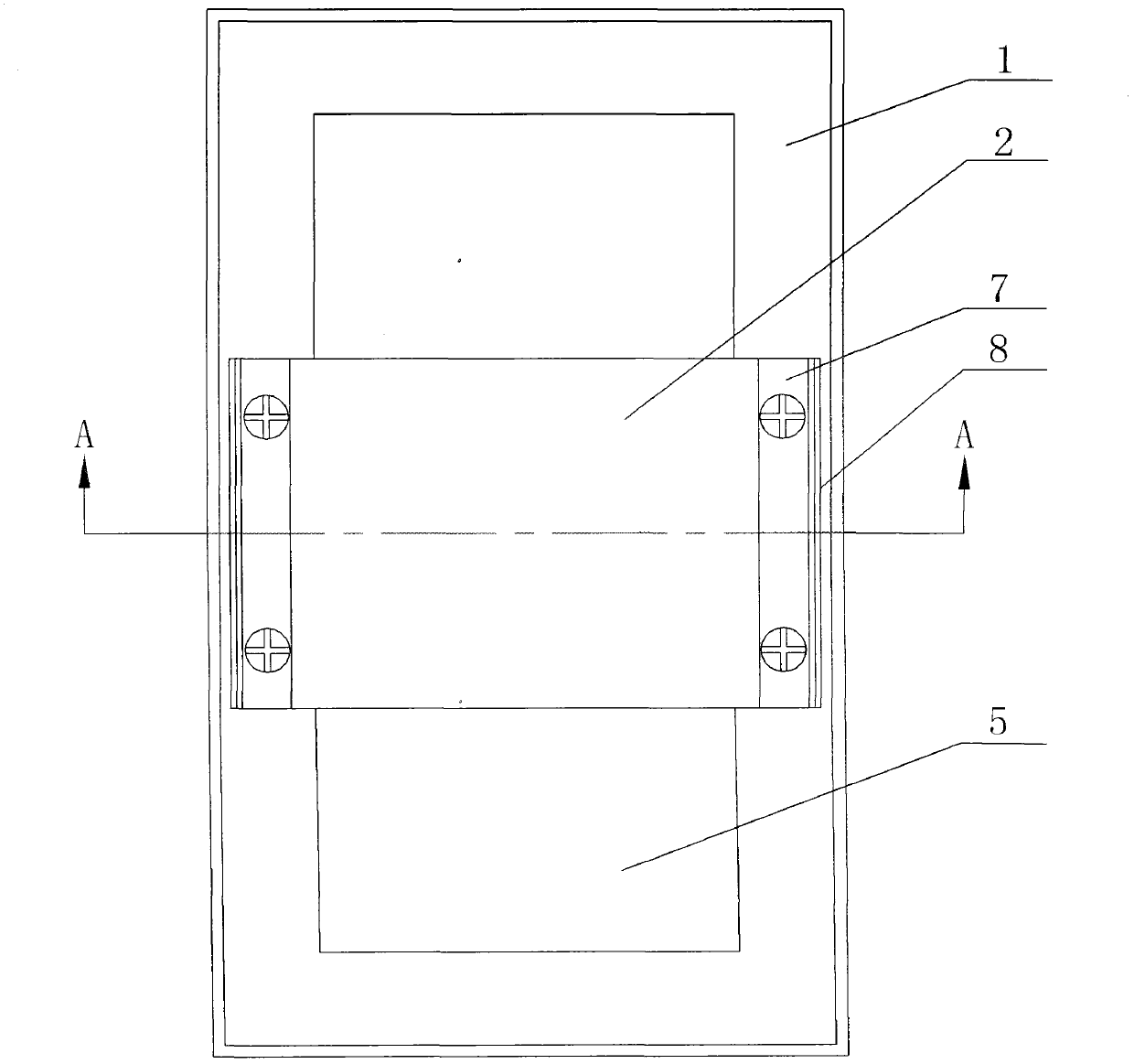

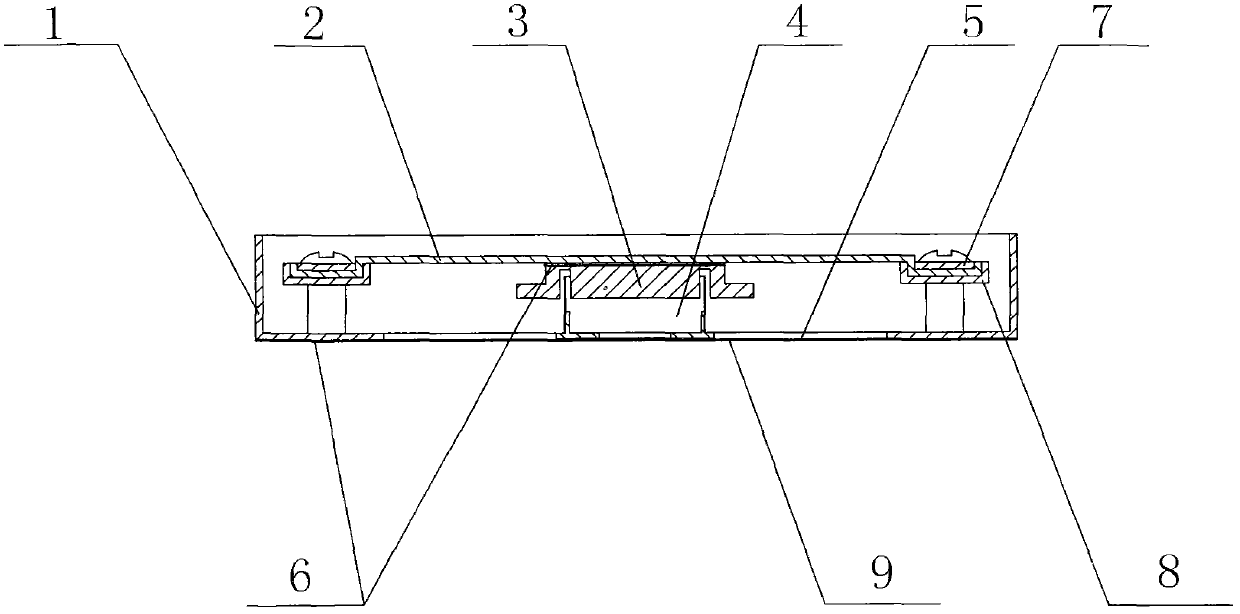

[0011] figure 2 Middle: The sounding film (5) is stuck on the fixed frame (1) through strong glue (6) and is in a tense state; the voice coil (4) is stuck on the sounding film (5) through strong glue (6) ; The magnetic steel (3) is stuck on the elastic connecting piece (2) through strong glue (6); the elastic connecting piece (2) is elastically fixed on the fixed frame through the upper pressing plate (7) and the concave lower pressing plate (8) (1) on.

[0012] figure 2 Shown upper block pressing plate (7) is to press elastic connecting piece (2) in the groove of concave lower pressing plate (8), so that adjust the elasticity of elastic connecting piece.

[0013] figure 1 When the middle sound film (5) is made of non-metallic flexible material such as polyester, its surface is coated with a layer of sealant (9), so as to avoid air leakage when vibrating and sounding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com