Method for recovering and processing isobutyraldehyde tail gas of storage tank and apparatus thereof

A tail gas recovery and storage tank technology, which is applied in the field of isobutyraldehyde tail gas recovery and treatment, can solve the problems of environmental pollution, high material loss of storage tanks, and human harm, and achieve the effects of preventing environmental pollution, low cost, and avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

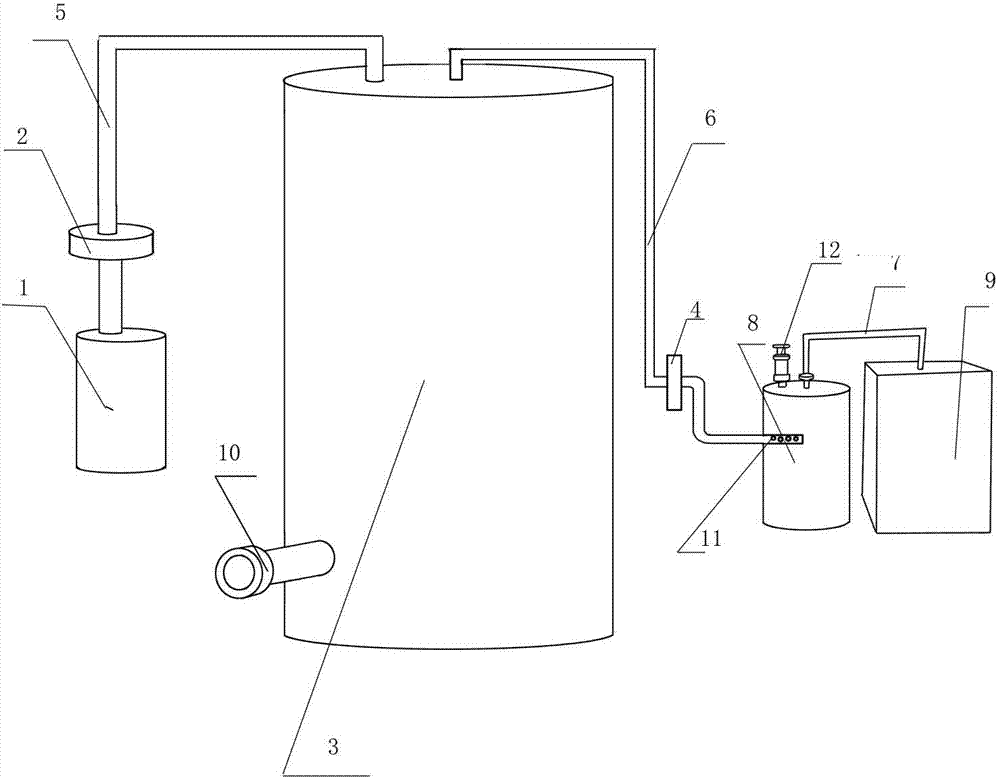

[0012] exist figure 1 Among them, the present invention provides a device for recovering and treating the isobutyraldehyde tail gas of the storage tank, which includes a nitrogen tank 1, a nitrogen air valve 2, a one-way valve 4, a gas delivery pipe I5, a gas delivery pipe II6, and a gas delivery pipe III7 , the reaction tank 8 and the water tank 9, the gas pipeline I5 is located between the nitrogen tank 1 and the top of the storage tank 3 for storing isobutyraldehyde, the nitrogen tank 1 communicates with the storage tank 3 through the gas pipeline I5, and the nitrogen air valve 2 is arranged on the gas pipeline I5 Above, the gas delivery pipe II6 is located between the storage tank 3 and the reaction tank 8 filled with methanol solution. The storage tank 3 communicates with the reaction tank 8 through the gas delivery pipe II6. Air nozzle 11, one-way valve 4 are arranged on the air delivery pipe II6, the one-way valve 4 is set as a one-way breathing valve, the air delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com