Medium plate double-frame rolling load distribution method

A technology of rolling load and distribution method, applied in the direction of metal rolling, etc., can solve the problem that there is no direct guidance on the production site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Taking rolling a 30mm steel plate as an example, the specific implementation of the present invention will be described.

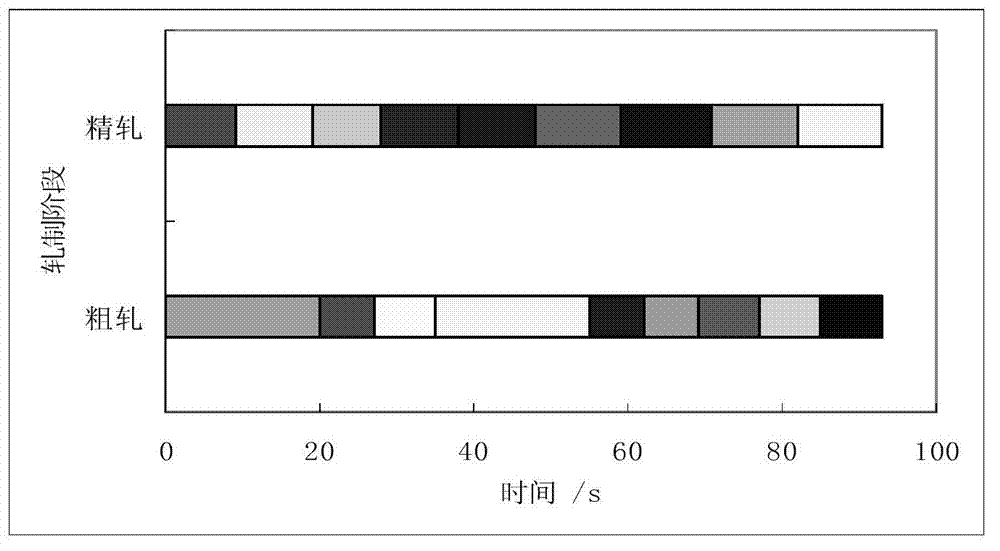

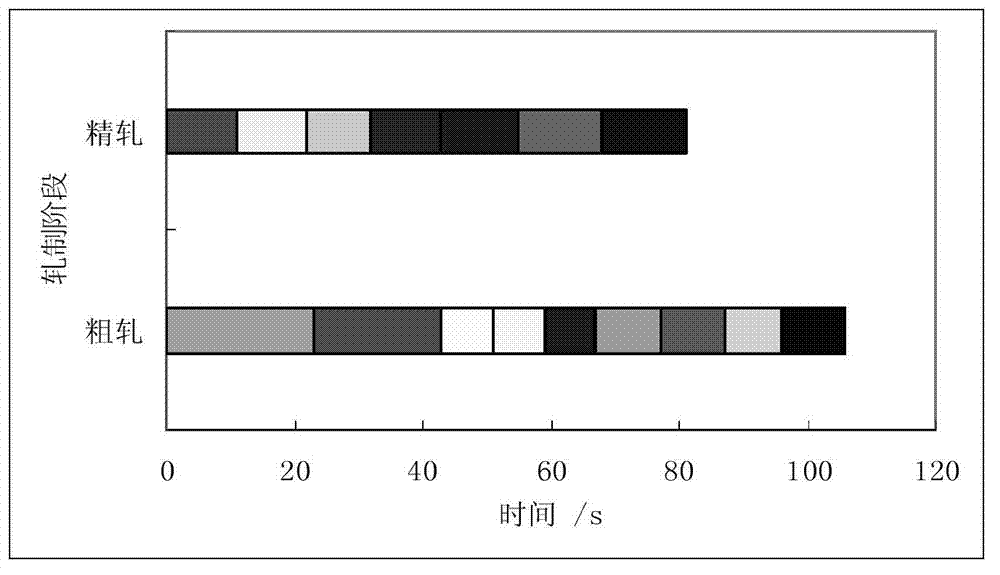

[0024] The same rolling time of the two rolling mills is the ultimate goal of improving the rolling rhythm. Therefore, the equal time mode is adopted to distribute the load of the double stand of the medium and heavy plate, that is, the time used by the two rolling mills is as equal as possible.

[0025] The two-stage rolling of 30 mm usually requires two steel transfers in the rough rolling stage. According to the summary of the invention, the optimal pass distribution is determined as the number of rolling passes in the finishing mill and the number of rolling passes in the roughing mill.

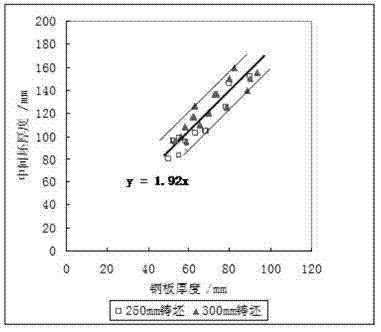

[0026] The thickness of 30mm steel plate is less than 50mm, and the optimum thickness to be heated is based on Figure 5 It can be determined that:

[0027] 30mm×2.11=63.3mm, floating 10mm up and down.

[0028] Taking 60mm as the thickness to be heated, we ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com