A symmetrical bifunctional photocatalyst, a dual-chamber photoreactor and a method for photocatalytic reduction of carbon dioxide

A technology of photocatalyst and photoreactor, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical/physical chemical processes that apply energy, etc., can solve the problems of energy input increase, energy loss, etc., and achieve enhanced ability, reduce energy consumption, and facilitate direct application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

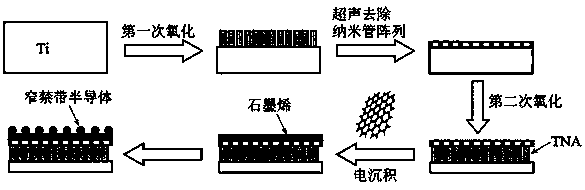

[0026] 1. Symmetrical bifunctional Cu 2 Preparation of O / G / TNA Film Photocatalyst

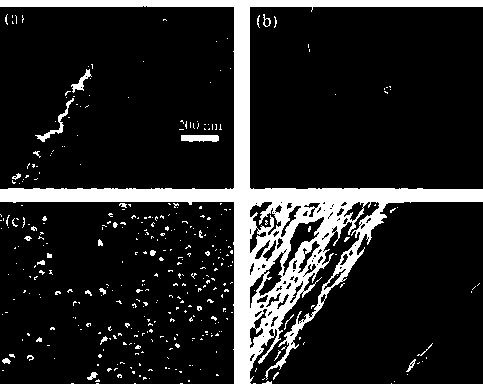

[0027] A symmetrical bifunctional photocatalyst, including double-sided TiO prepared from pure titanium by two-step anodic oxidation 2 Nanotube array (TNA) film substrate, the surface of the substrate is electrodeposited with a graphene layer, and the thickness of the graphene deposition layer is changed by adjusting the electrochemical parameters, thereby regulating the electron transport in the composite symmetrical bifunctional photocatalyst and improving the photoelectron-hole on the recombination probability; then deposit narrow-bandgap semiconductor nanoparticles on the graphene layer as a photosensitizer, and its preparation process is as follows figure 1 shown, including the following steps:

[0028] (1) Preparation of TNA film substrate: After physical grinding and ultrasonic cleaning, the pure titanium foil was soaked in chemical pickling solution for chemical polishing; then the ti...

Embodiment 2~5

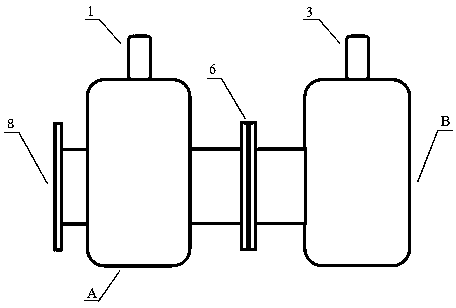

[0036] Embodiment 2,3,4,5 The method for preparing TNA film substrate is the same as embodiment 1, prepares G / TNA substrate and Cu 2 The process of O / G / TNA substrate refers to embodiment 1, and concrete process parameter is shown in Table 1, and corresponding Cu 2 The O / G / TNA substrates are labeled as sample 2, sample 3, sample 4, and sample 5 in sequence.

[0037] Sample 2, sample 3, sample 4, sample 5 are respectively clamped in the middle of the connection port 6 of the double-chamber photoreactor of embodiment 2, 3, 4, 5, and the type of electrolyte solution injected in the anode reaction pool A and the cathode reaction pool B See Table 1.

[0038] Example 2, 3, 4, 5 photocatalytic reduction of CO 2 The process of preparing methanol experiment is the same as in Example 1.

[0039] The technological parameter table of table 1 embodiment 1~5

[0040]

Embodiment 6

[0042] The preparation process of the G / TNA film substrate is the same as that of Example 1.

[0043] CdS is deposited on the surface of G / TNA by hydrothermal precipitation method. The process is: respectively prepare cadmium chloride aqueous solution and thiourea aqueous solution with a concentration of 0.004mol / L, according to cadmium chloride aqueous solution: thiourea aqueous solution (mass ratio ) in a ratio of 1:3 and mixed evenly. The G / TNA membrane substrate was placed vertically in a high-pressure reactor, and a mixed solution of cadmium chloride and thiourea was added, and the sealed reactor was placed in an oven at 170 °C for 6 h. After the reaction, the sample was taken out, washed with distilled water, and then heat-treated at 400 °C for 3 h in an Ar atmosphere to prepare a CdS / G / TNA film substrate.

[0044] The CdS / G / TNA film substrate is clamped in the middle of the connection port 6 of the double-chamber photoreactor, and the photocatalytic reduction of CO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com