Automatic control system of electromagnetic induction furnace and method of system

A technology of electromagnetic induction furnace and rolling parts, which is applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as cost, and achieve the effect of ensuring the quality and performance of finished products and meeting the requirements of narrow window technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

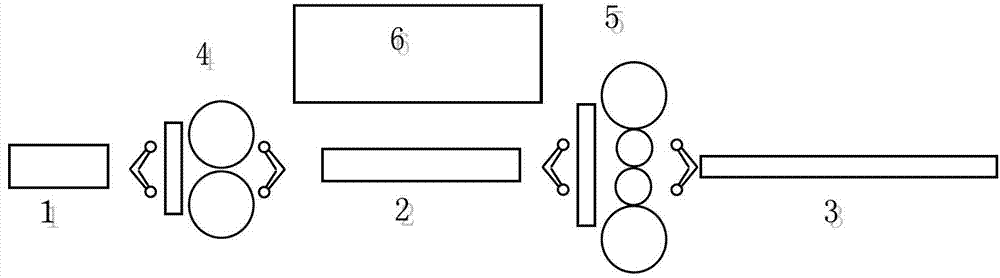

[0019] Taking the production of high-grade oriented silicon steel finished strip steel as an example, the raw material slab specification is 230*1100mm, and the finished strip steel specification is 2.3*1100mm; an electromagnetic induction furnace automatic control system provided by the embodiment of the present invention includes a slab raw data processing module , the second-level model calculation module, the rolling line tracking module and the first-level PLC control module, the slab raw data processing is used to receive the set number of passes of E1R1 rolling mill 4 and the set number of passes of E2R2 rolling mill 5, and receive the set rolled pieces The target width and the target thickness of the rolled piece receive the set target width and target thickness of the intermediate billet, and the second-level model calculation module is based on the number of passes of the E1R1 rolling mill 4, the number of passes of the E2R2 rolling mill 5, the target width of the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com