Black reactive dyestuff and preparation method thereof

A reactive dye and black technology, which is applied in the field of black reactive dye and its preparation, can solve the problems that the blackness and fastness cannot reach the same level, and cannot really replace medium black PV, etc., and achieve the effect of improving color fixation rate and fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A kind of preparation method of black reactive dye, comprises the steps:

[0058] a. Preparation of condensate diazonium salt: Add 2.4-sodium diaminobenzenesulfonate to water, control the temperature at 2-8°C with ice, add 2.3-dibromopropionyl chloride, and control with 10--20% sodium carbonate solution pH = 6-8, react for 3-6 hours, and the reaction temperature is always controlled at 2-8°C to obtain a condensate suspension; add hydrochloric acid and ice to the condensate suspension, cool down to 0-5°C, add sub Sodium nitrate, react at 7-14°C for 1-2 hours, keep a slight excess of sodium nitrite throughout the reaction, add sulfamic acid H 2 NSO 3 H removes excess sodium nitrite;

[0059] b. Preparation of dinitroaniline diazonium salt: add sodium nitrite to 98% sulfuric acid, control the temperature below 30°C, heat up to 65--70°C after adding, keep warm for 2-3 hours; cool down to 30°C Next, add dinitroaniline, control the temperature below 40°C, keep warm at 40±3...

Embodiment 1

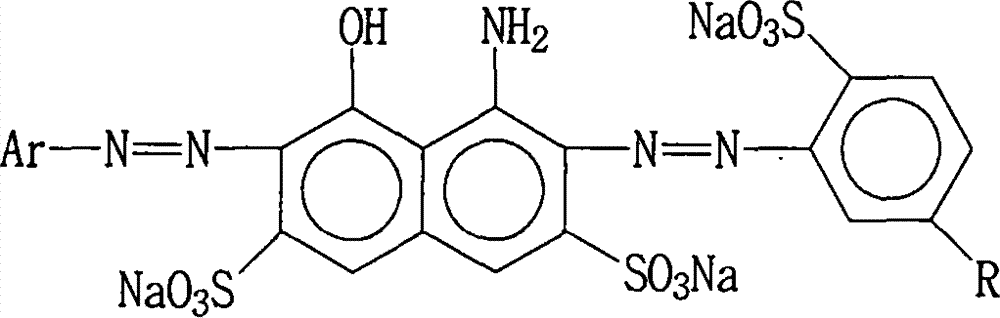

[0098] Structure 1

[0099]

[0100] 1. Preparation of Condensate

[0101] Add 420kg of sodium 2.4-diaminobenzenesulfonate to 7500L of water, control the temperature at 2-8°C with ice, add 515kg of 2.3-dibromopropionyl chloride, control the pH=6-8 with 10--20% sodium carbonate solution, and react 3--6 hours, the reaction temperature is always controlled at 2--8 °C. The condensate suspension was obtained and set aside.

[0102] 2. Preparation of condensate diazonium salt

[0103] Add 560 kg of 30% hydrochloric acid to the condensate suspension in step 1, add ice and cool down to 0-5°C. Add a solution containing 138kg of sodium nitrite, the concentration of the solution is 30-40%, and react at 7-14°C for 1-2 hours. After the reaction is complete, add H 2 NSO 3 H (sulfamic acid) removes excess sodium nitrite.

[0104] 3. Preparation of p-nitroaniline diazonium salt

[0105] Add 12kg of Brigade-12 surfactant, 238.6kg of p-nitroaniline, and 543kg of 30% hydrochloric acid...

Embodiment 2

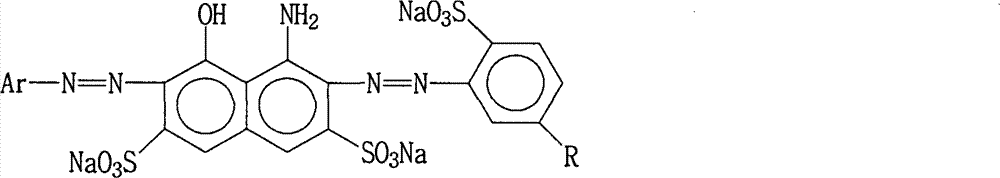

[0115] Structure 2

[0116]

[0117] 1. Preparation of p-nitroaniline diazonium salt

[0118] Add 12kg of Brigade-12 surfactant, 238.6kg of p-nitroaniline, and 543kg of 30% hydrochloric acid in 7500L of water, beat for one hour, add ice to cool to 0--5°C, add 138kg of sodium nitrite solution, the solution concentration is 30 -40%, react at 0-5°C for 2-3 hours, add sulfamic acid after the reaction, and remove excess nitrous acid.

[0119] 2. Preparation of sulfonated meta-ester diazonium salt

[0120] Add 722kg of sulfonated meta-ester and 317kg of 30% hydrochloric acid to 7500L water, add ice to cool down to 0--5°C, add 138kg of sodium nitrite solution, the solution concentration is 30-40%, and react at 0--5°C for 4- -6 hours, after the reaction is complete, add sulfamic acid to remove excess nitrous acid. .

[0121] 3. One-step coupling

[0122] In the diazonium salt in step 2, add H acid directly, control the temperature at 10--15°C, and react for more than 6 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com