Method and tool for mounting brake system pipeline of aluminum alloy vehicle

A vehicle braking and braking system technology, which is applied in the field of rail vehicles, can solve problems affecting the air tightness of pipelines, waste of human resources, pipeline deformation, etc., and achieve the goal of improving installation efficiency, simplifying installation steps, and improving installation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

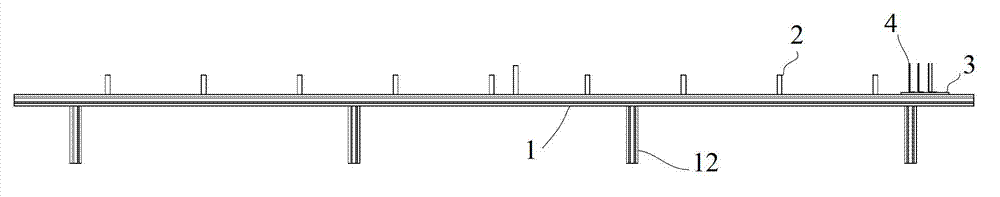

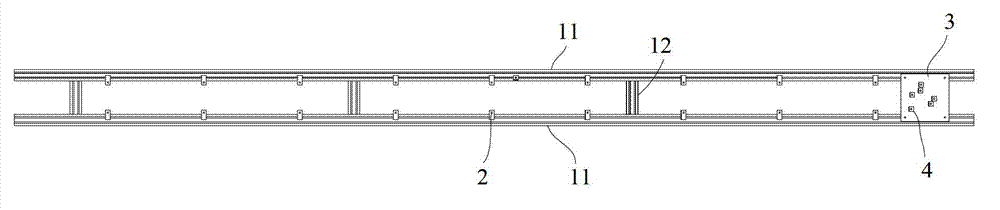

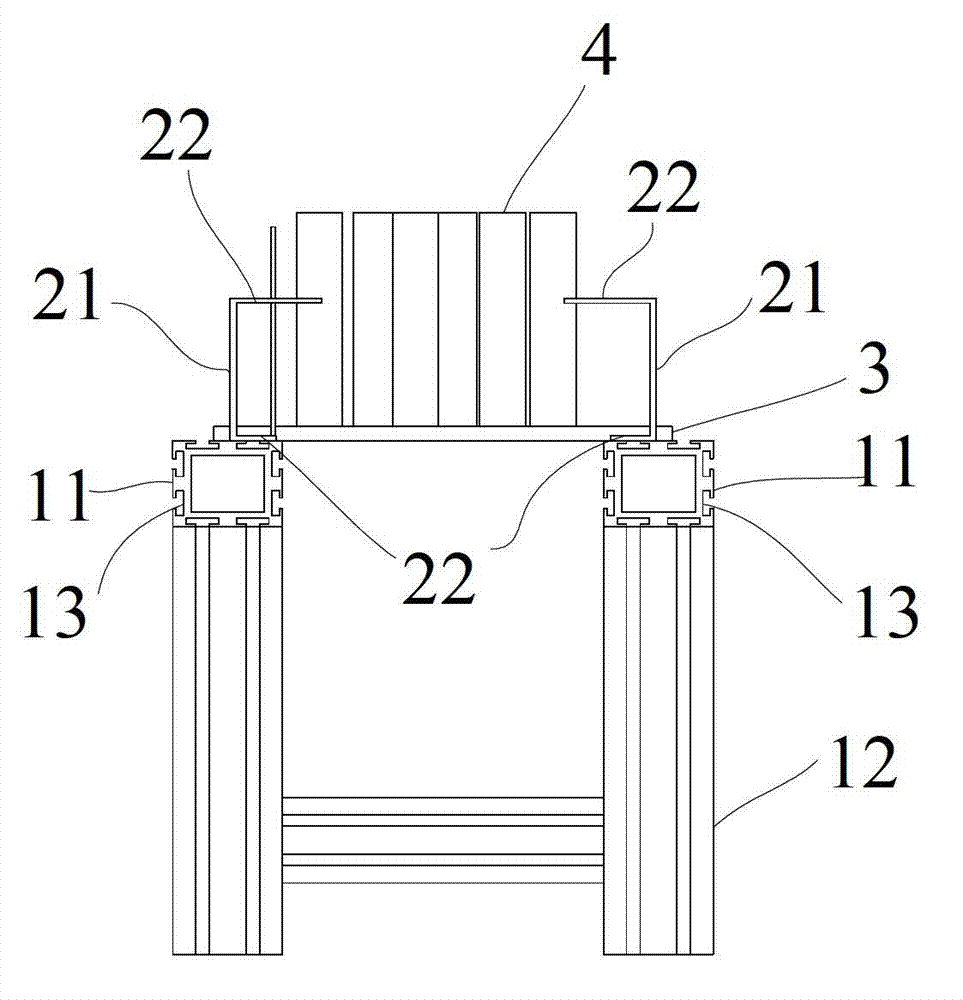

[0026] like Figure 8 As shown, the embodiment of the present invention provides an aluminum alloy vehicle brake system pipeline installation method, including the following steps:

[0027] S1: Make the tooling, the structure of the tooling is as follows Figure 1-3 As shown, the tooling is composed of a base frame 1, a plurality of pipe holder brackets 2 installed on the base frame along the length direction of the base frame 1, and a plurality of positioning baffles 4 for positioning one end of the brake system pipeline. The baffles 4 are all vertically placed on the end plate 3 at one end of the chassis 1, wherein the position of the tube holder bracket 2 is adapted to the hoisting position on the bottom of the aluminum alloy vehicle;

[0028] S2: install the tube holders 20 on the brackets 2 of the tube holders respectively and fasten them;

[0029] S3: arranging the tube clips 10 on each tube clip holder 20 as required;

[0030] S4: Connect the brake system pipeline 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com