Process for manufacturing preformed color-stone concrete composite veneers

A color stone concrete and veneer technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult control of production scale, complex production process, loose stones, etc., and achieve novel colors, easy operation, and increased output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Production of colored stone concrete composite prefabricated decorative parts:

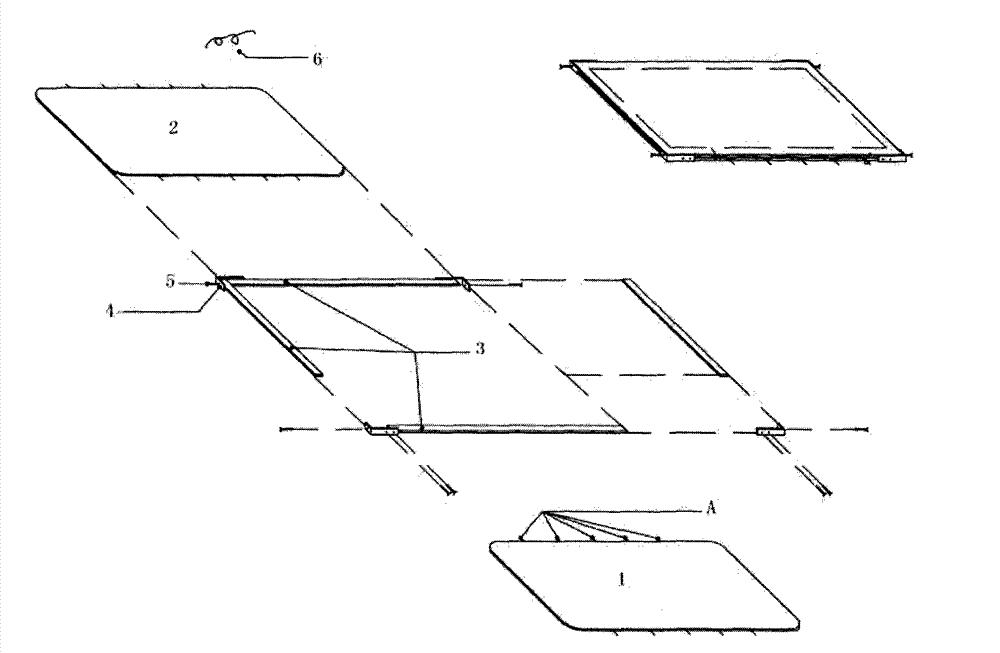

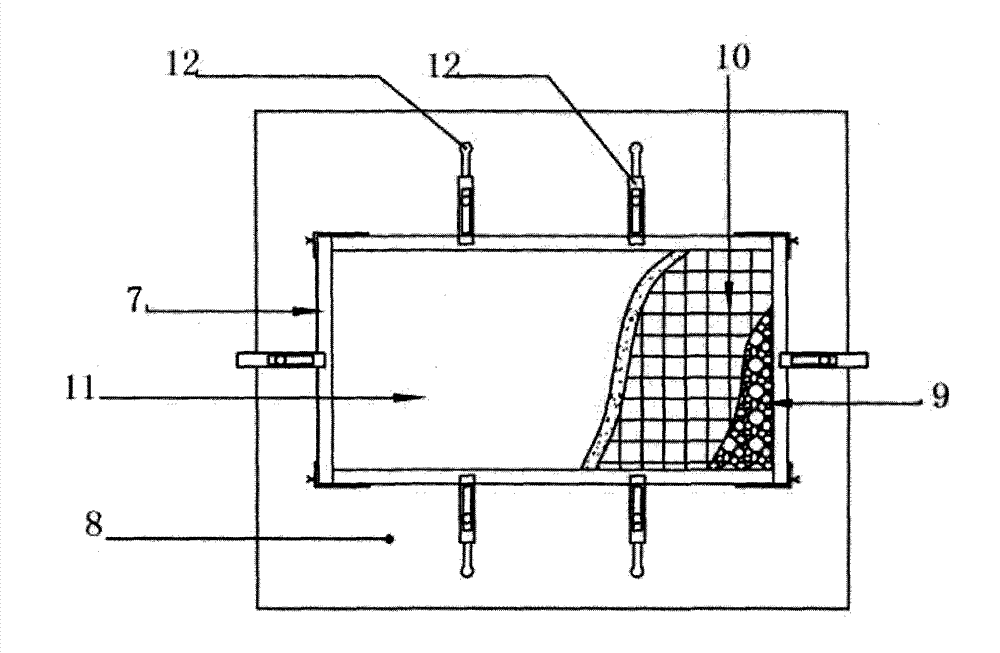

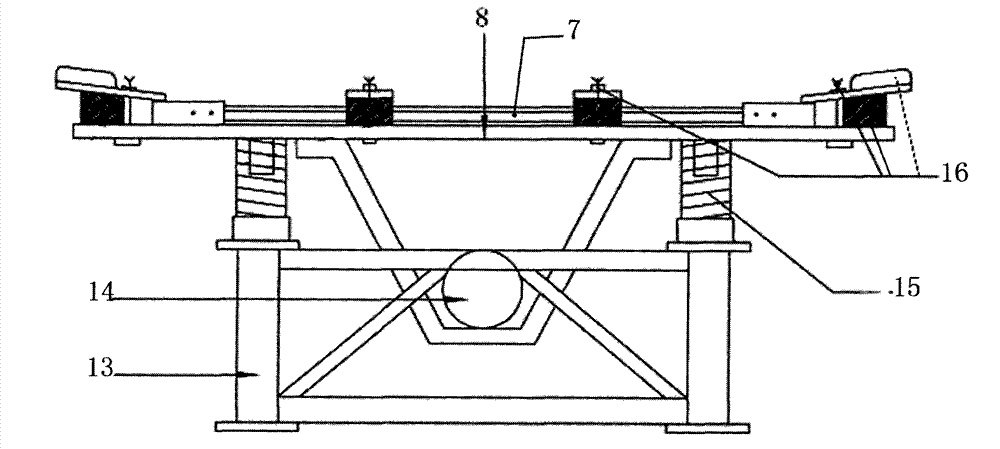

[0022] ①. Rough board production - fix the closed mold bottom plate (1) and mold frame (3) on the vibrating table panel (8) through the moving chute (12) and fastening clip (16), and paint on the mold Release agent; mix cement and selected pebbles or colored gravels (including stone handicrafts, colored waste slag of architectural decorative stones into gravels) in a weight ratio of 1:2 to 1:2.5, and add appropriate amount of pigments and clear water, put it into the mixer and stir for 3-5 minutes, then put the stirred mixture into the clamped mold; the capacity is based on 2 / 3 of the height of the mold frame (3), and the surface of the colored stones is closely attached to the closed mold through vibration. formwork bottom plate (1), so that all stone surfaces are kept on the same level, thereby forming a colored stone concrete layer (9); Stone concrete (11) forms a layered state, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com