Three-dimensional light-sensing super-soft weft knitted fabric and preparation method thereof

A knitted fabric and light-sensing technology, applied in the field of knitted fabrics, can solve the problems of low fabric appearance quality, poor wearing comfort, poor decorative performance, etc., and achieve the effect of novel color, strong three-dimensional effect and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 The embodiment of the present invention provides a method for preparing a three-dimensional light-sensitive supersoft warp-knitted fabric, which specifically includes the following steps:

[0028] (1) Preparation of functional yarns: use fine denier bright triangular shaped FDY fibers and natural cotton fibers to process into low-twisted composite yarns through drawing, roving, spun yarn, and winding processes; use polyester DTY fibers and nylon gold and silver The monofilament is made into polyester flashing fiber by melt spinning method, and then polyester flashing composite yarn is made through cotton cleaning and carding process;

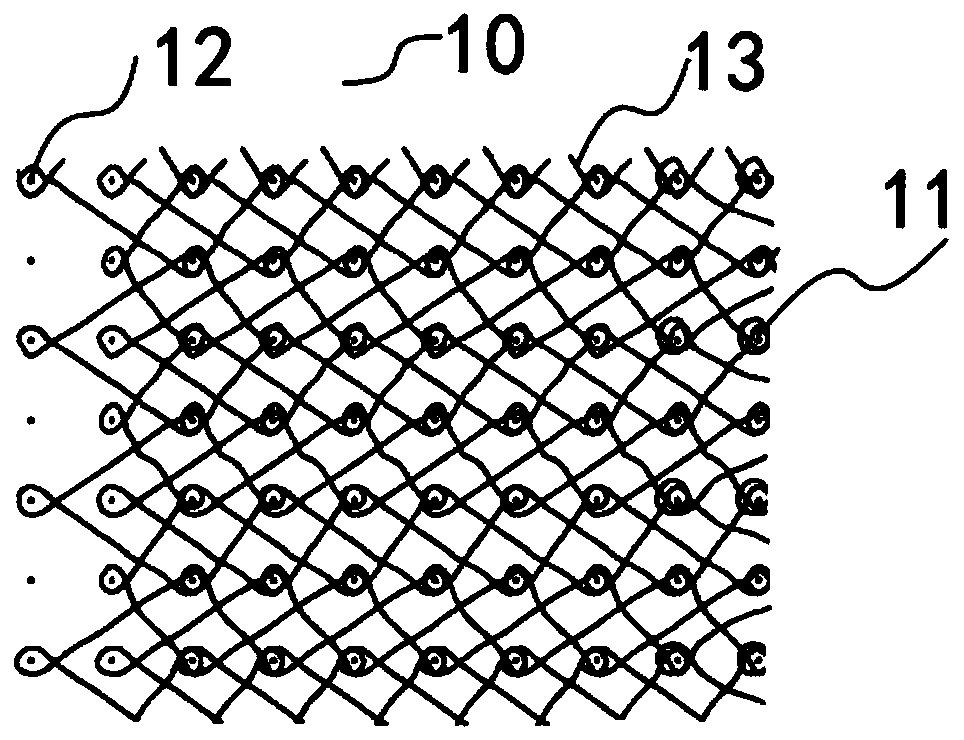

[0029] (2) Gray fabric weaving: use low-twisted composite yarn as the first strand, polyester flashing composite yarn as the second strand, and spandex yarn as the third strand, and warp knitting process is used to interweave gray fabric; Wherein, the first yarn is a pile structure, the second yarn is a pile structure, and th...

Embodiment 2

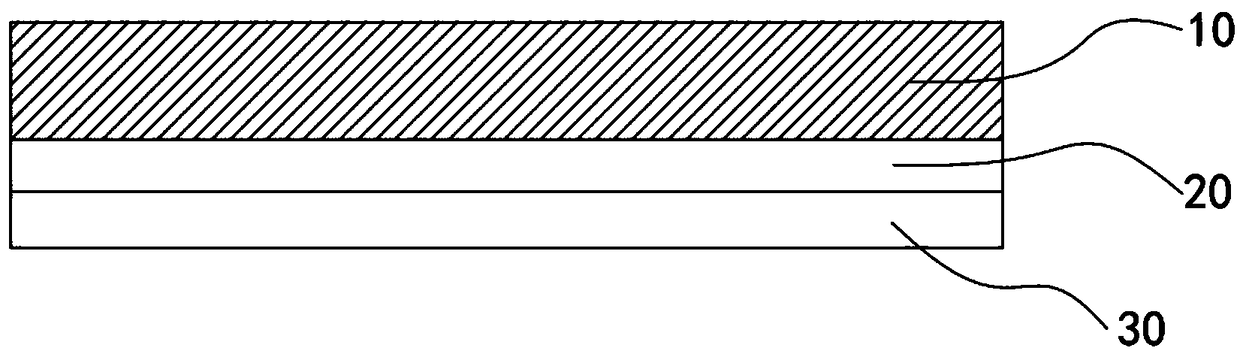

[0040] Example 2 as figure 1 As shown, the embodiment of the present invention also provides a three-dimensional photosensitive super soft warp knitted fabric prepared by the above method, including a fabric body 10 and an antibacterial layer 20 and a flocking layer 30 arranged on the back of the fabric body 10, antibacterial Layer 20 can block bacteria, prevent bacteria from passing through the fabric body 10 and contact with the human body, and the flocking layer 30 can improve the feel of the fabric; the fabric body 10 includes three strands of yarn interwoven by warp knitting, and the three strands of yarn The line includes the low-twisted composite yarn as the first strand 11, the polyester flashing composite yarn as the second strand 12, and the spandex yarn as the third strand 13, and the first yarn is The pile weave structure, the second yarn is a pile weave structure, and the third yarn is a warp weave structure.

[0041] In this embodiment, the first strand 11 adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com