Pink yttrium-zirconium structural ceramic and its preparation method

A technology for pink and ceramic products, which is applied in the field of pink yttrium-zirconium structural ceramics and its preparation, and can solve the problems of unreported yttrium-zirconium structural ceramic products and single color types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

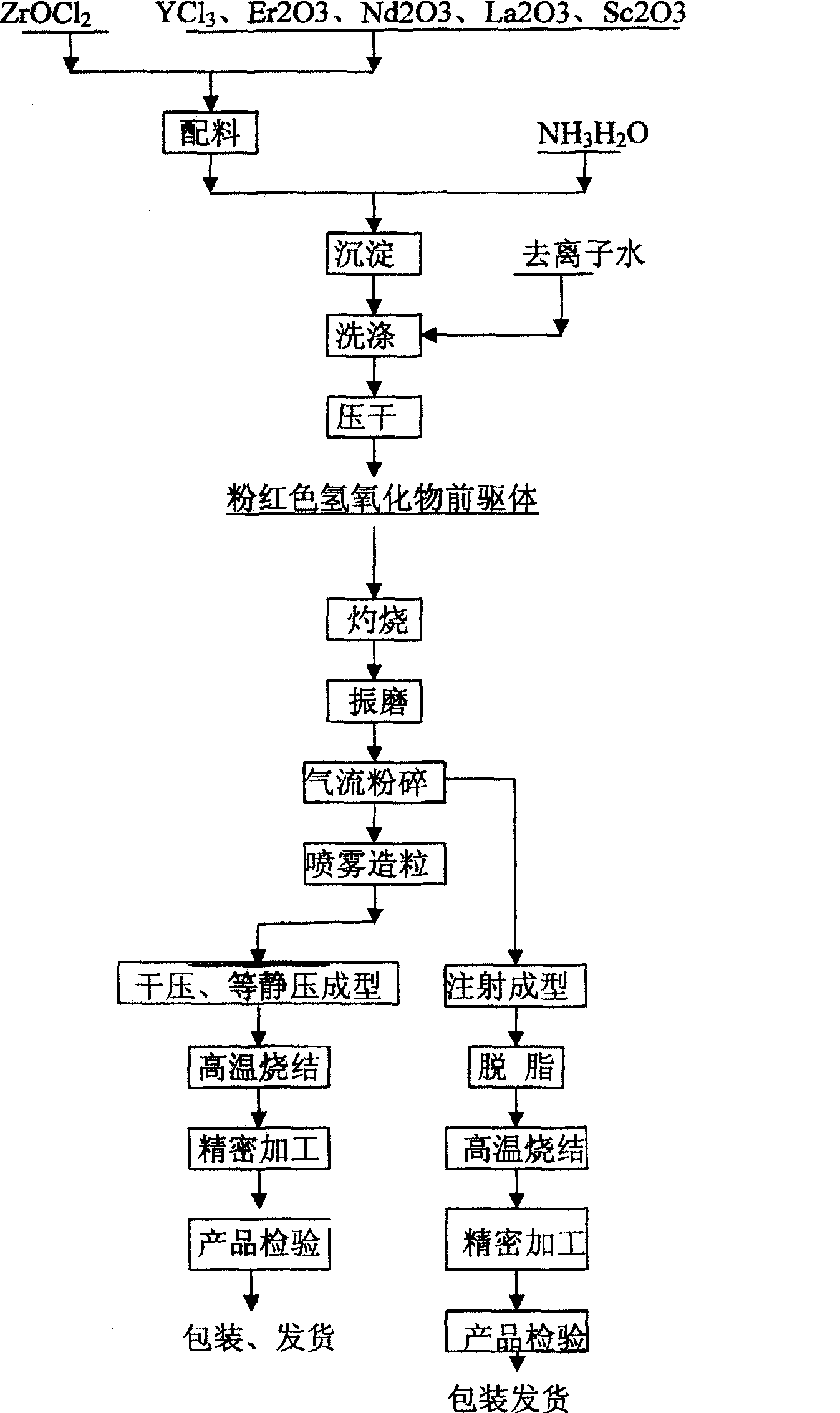

[0017] see figure 1 , Step 1: Dissolve zirconium oxychloride in water to form 80 g / L, Y 2 o 3 、Nd 2 o 3 、Er 2 o 3 , La 2 o 3 、Sc 2 o 3 Dissolved with nitric acid to make 0.5mol / l respectively, 100 kilograms of ingredients (converted into oxide): ZrO2=93.6 kilograms, Y 2 o 3 = 5.2 kg, Nd 2 o 3 = 0.4 kg, Er 2 o 3 = 0.6 kg, La 2 o 3 = 0.1 kg, Sc 2 o 3 =0.1 kilogram, get the volume number of above-mentioned material respectively: 1170 liters, 92.12 liters, 4.76 liters, 6.28 liters, 1.23 liters, 2.90 liters, join in the mixing tank of 2000 liters successively, stir and mix for subsequent use;

[0018] Step 2: Precipitate by chemical co-precipitation method, the reaction process is: add 500L of deionized water and dispersant (dispersant / material weight = 1.2%) in the reactor, slowly heat up to 60 ° C, and slowly add feed liquid ( In the step 1, the batching liquid) and precipitating agent (ammonia, concentration is 3N), the control reaction temperature is 60 ℃, th...

Embodiment 2

[0024] see figure 1 , Step 1: Dissolve zirconium oxychloride in water to form 80 g / L, Y 2 o 3 、Nd 2 o 3 、Er 2 o 3 , La 2 o 3 、Sc 2 o 3 Dissolved with nitric acid to make 0.5mol / l respectively, 100 kilograms of ingredients (converted into oxide): ZrO2=92.1 kilograms, Y 2 o 3 = 5.0 kg, Nd 2 o 3 = 0.7 kg, Er 2 o 3 = 1.5 kg, La 2 o 3 = 0.4 kg, Sc 2 o 3 =0.3 kilograms, get the volume numbers of above-mentioned materials respectively: 1151 liters, 88.57 liters, 8.32 liters, 15.69 liters, 4.91 liters, 8.71 liters, add successively in the mixing tank of 2000 liters, stir and mix for subsequent use.

[0025] Step 2: Precipitate by chemical co-precipitation method, the reaction process is: add 500L of deionized water and dispersant (dispersant / material weight = 1.2%) in the reactor, slowly heat up to 60 ° C, and slowly add feed liquid ( In the step 1, the batching liquid) and precipitating agent (ammonia, concentration is 3N), the control reaction temperature is 60 ℃,...

Embodiment 3

[0031] see figure 1 , Step 1: Dissolve zirconium oxychloride in water to form 80 g / L, Y 2 o 3 、Nd 2 o 3 、Er 2 o 3 , La 2 o 3 、Sc 2 o 3 Dissolved with nitric acid to make 0.5mol / l respectively, 100 kilograms of ingredients (converted into oxide): ZrO2=92.0 kilograms, Y 2 o 3 = 4.0 kg, Nd 2 o 3 = 0.3 kg, Er 2 o 3 = 3.5 kg, La 2 o 3 = 0.1 kg, Sc 2 o 3 =0.1 kilogram, get the volume number of above-mentioned material respectively: 1150 liters, 70.86 liters, 3.56 liters, 36.61 liters, 1.23 liters, 2.90 liters, join in the mixing tank of 2000 liters successively, stir and mix for subsequent use;

[0032] Step 2: Precipitate by chemical co-precipitation method, the reaction process is: add 500L of deionized water and dispersant (dispersant / material weight = 1.2%) in the reactor, slowly heat up to 60 ° C, and slowly add feed liquid ( In the step 1, the batching liquid) and precipitating agent (ammonia, concentration is 3N), the control reaction temperature is 60 ℃, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com