Golden yellow Y-Zr structural ceramics and preparation method thereof

A technology of golden yellow and ceramic products, which is applied in the field of structural ceramics and can solve problems such as single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

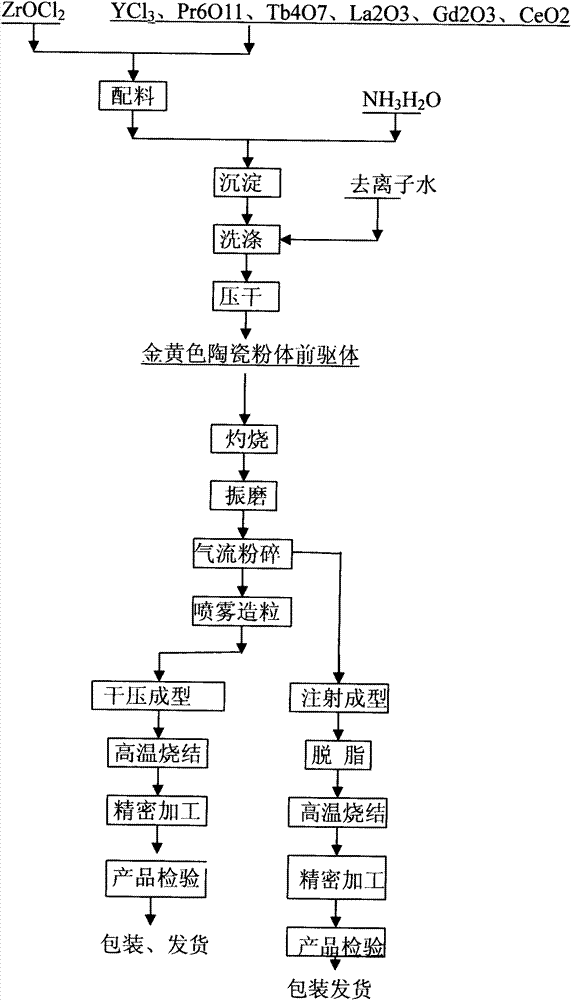

[0019] see figure 1 , Step 1: Dissolve zirconium oxychloride in water to make 80 g / L (use ZrO 2 count), Y 2 o 3 , Tb 4 o 7 、Pr 6 o 11 , La 2 o 3 、Gd 2 o 3 , CeO 2 Dissolve with nitric acid to make 0.50mol / L nitrate solution respectively, ingredients 100kg (calculated as oxide): take ZrO 2 =82.95kg, Y 2 o 3 =5.2kg, Tb 4 o 7 =0.4kg, Pr 6 o 11 =1.2kg, La 2 o 3 =0.05kg, Gd 2 o 3 =0.2kg, CeO 2 =10.0kg, join in the reactor of 2000 liters, stir and mix for subsequent use.

[0020] Step 2: Prepare the golden yellow yttrium zirconium hydroxide precursor by chemical co-precipitation method, the process is: 3m 3 Add 500L of deionized water and 1.2kg of dispersant to the enamel reaction kettle, stir evenly, slowly raise the temperature to 60°C, and simultaneously slowly add the ingredients in step 1 and ammonia water with a concentration of 3N, control the reaction temperature at 60-65°C, and control the final reaction temperature. The pH value is 8, and the reacti...

Embodiment 2

[0026] see figure 1 , Step 1: Dissolve zirconium oxychloride in water to form 81 g / L (in the form of ZrO 2 count), Y 2 o 3 , Tb 4 o 7 、Pr 6 o 11 , La 2 o 3 、Gd 2 o 3 Dissolved with nitric acid to make 0.51mol / L nitrate solution respectively, ingredients 100kg (converted into oxide): take ZrO 2 =88.0kg, Y 2 o 3 =4.0kg, Tb 4 o 7 =1.5kg, Pr 6 o 11 =5.0kg, La 2 o 3 =0.4kg, Gd 2 o 3 =0.1kg, CeO 2 =1.0kg, add it into a 2000-liter mixing tank and mix well for later use.

[0027] Step 2: Prepare the golden yellow yttrium zirconium hydroxide precursor by chemical co-precipitation method, the process is: 3m 3Add 500L of deionized water and 1.2kg of dispersant to the enamel reaction kettle, stir evenly, slowly raise the temperature to 65°C, and simultaneously slowly add the batching liquid and ammonia water with a concentration of 3N in step 1, and control the reaction temperature to 60-65°C. The final pH value of the process is 9, and the reaction time is 3 hours....

Embodiment 3

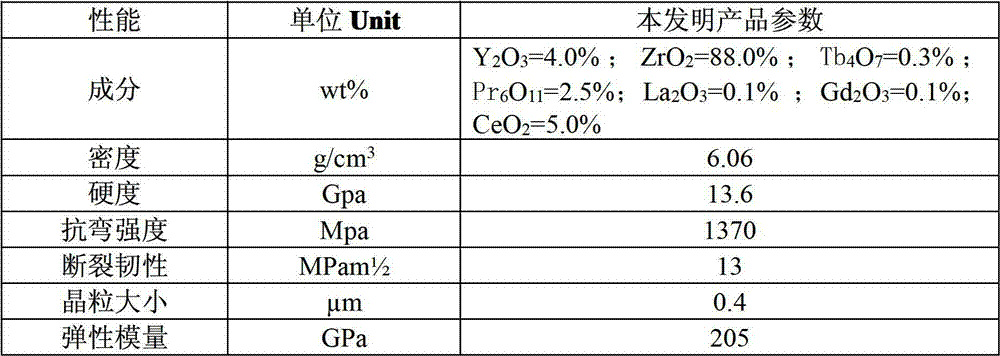

[0032] see figure 1 , Step 1: Dissolve zirconium oxychloride in water to form 80 g / L, Y 2 o 3 、Nd 2 o 3 、Er 2 o 3 , La 2 o 3 、Sc 2 o 3 Dissolved with nitric acid to make 0.50mol / l respectively, and 100 kg of ingredients are converted into oxides) to take ZrO 2 =88.0 kg, Y 2 o 3 =4.0 kg, Tb 4 o 7 =0.3 kg, Pr 6 o 11 =2.5 kg, La 2 o 3 =0.1 kg, Gd 2 o 3 =0.1 kg, CeO 2 =5.0kg, successively added to a 2000-liter mixing tank, stirred and mixed for later use;

[0033] Step 2: Precipitate by chemical co-precipitation method, the reaction process is: 3m 3 Add 500L of deionized water and 1.2kg of dispersant to the enamel reaction kettle, stir evenly, slowly raise the temperature to 60°C, and simultaneously slowly add the batching liquid in step 1 and the ammonia precipitation agent with a concentration of 3N, and control the reaction temperature to 60-65°C. The final pH value of the reaction process is 8-9, and the reaction time is 2 hours. After the reaction is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com