Telescopic guardrail for mounting

A technology for installation and guardrails, applied in transportation and packaging, elevators, elevators in buildings, etc., can solve problems such as car top operators falling down the shaft, dangerous structural form, etc., and achieve the effect of improving the load-bearing function and improving the telescopic column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

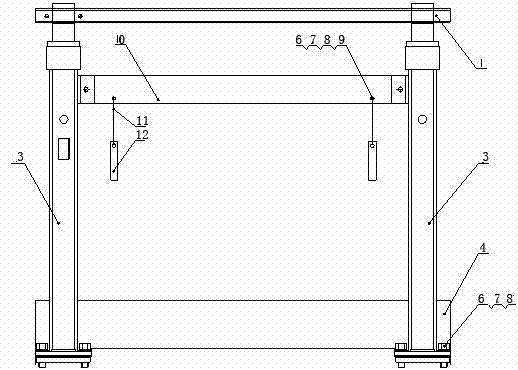

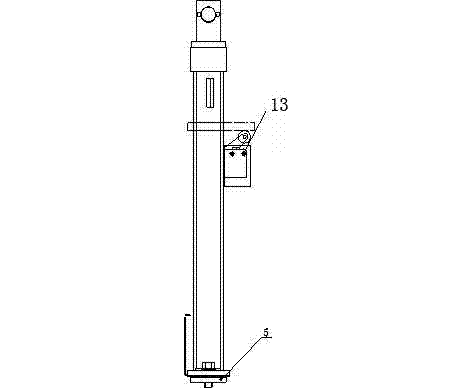

[0014] A telescopic guardrail for installation, comprising a movable horizontal tube 1 and a foot guard 2, a pair of telescopic columns 3 are arranged between the movable horizontal tube 1 and the toe guard 2, and a guardrail is installed between the pair of telescopic columns 3 The fixed horizontal plate 10 is also provided with a guardrail mounting plate 5 at the bottom of the toe guard 2 , and the fixed horizontal plate 10 of the guardrail is provided with a latch 12 through a rope 11 . The length of the movable horizontal tube 1 is 285mm, the distance from the center of the toe guard 2 to the fixed horizontal plate 10 is 465mm, and the width of the guardrail mounting plate 5 is 100mm. A spring washer 6, a flat washer 7 and a hexagonal bolt 8 are also installed at the guardrail mounting plate 5 installation places. Rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com