Elastic foil dynamic pressure air flotation radial bearing, motor and air compressor

An elastic foil and radial bearing technology, applied in the fields of motors, elastic foil dynamic pressure air-floating radial bearings, and air compressors, can solve the problems of smaller inner diameter and reduced performance, and increase the bearing area and improve Bearing performance, the effect of preventing end leakage of the gas film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

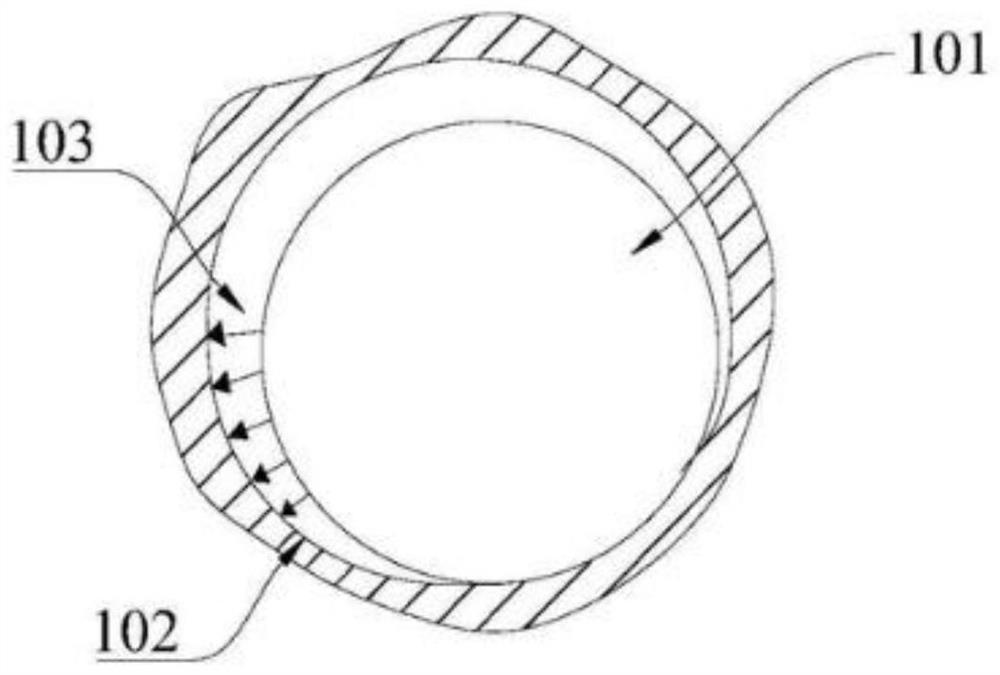

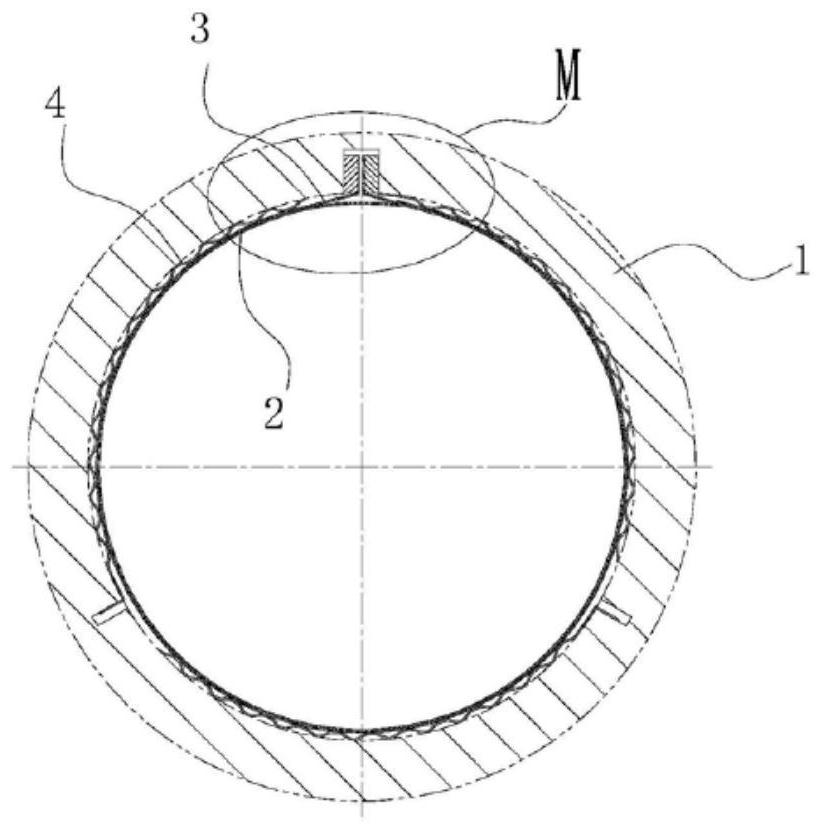

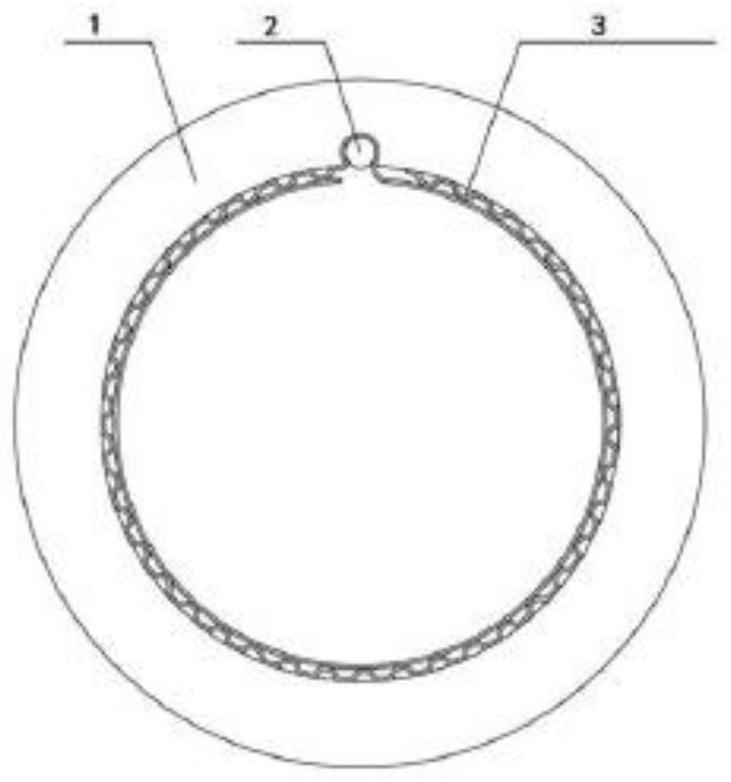

[0036] see in conjunction Figure 1 to Figure 11 As shown, according to an embodiment of the present invention, an elastic foil dynamic pressure air bearing radial bearing is provided, including a bearing seat 1, a top foil 3 arranged in the inner hole of the bearing seat 1, and a top foil 3 supported on the bearing The support foil 2 between the inner hole of the seat 1 and the outer peripheral wall of the top foil 3, the top foil 3 is a full circle structure, and the whole circle structure is a complete cylindrical or ring shape as a whole structure. In this technical solution, the top foil 3 is a full circle structure, that is, there is no free end in the prior art, and there is no interference of the free end in the inner circle of the bearing top foil, and the bearing area is increased, so that the radial bearing can be improved. Excellent load-carrying performance, which completely eliminates the phenomenon of air film end leakage at the free end of the top foil in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com