High-bearing gear bearing

A gear bearing and high-load-bearing technology, which is applied to ball bearings, bearing components, shafts and bearings, etc., can solve the problems of poor power transmission reliability, heavy quality, and large number of components, and achieve low running noise, increased service life, and improved The effect of bearing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

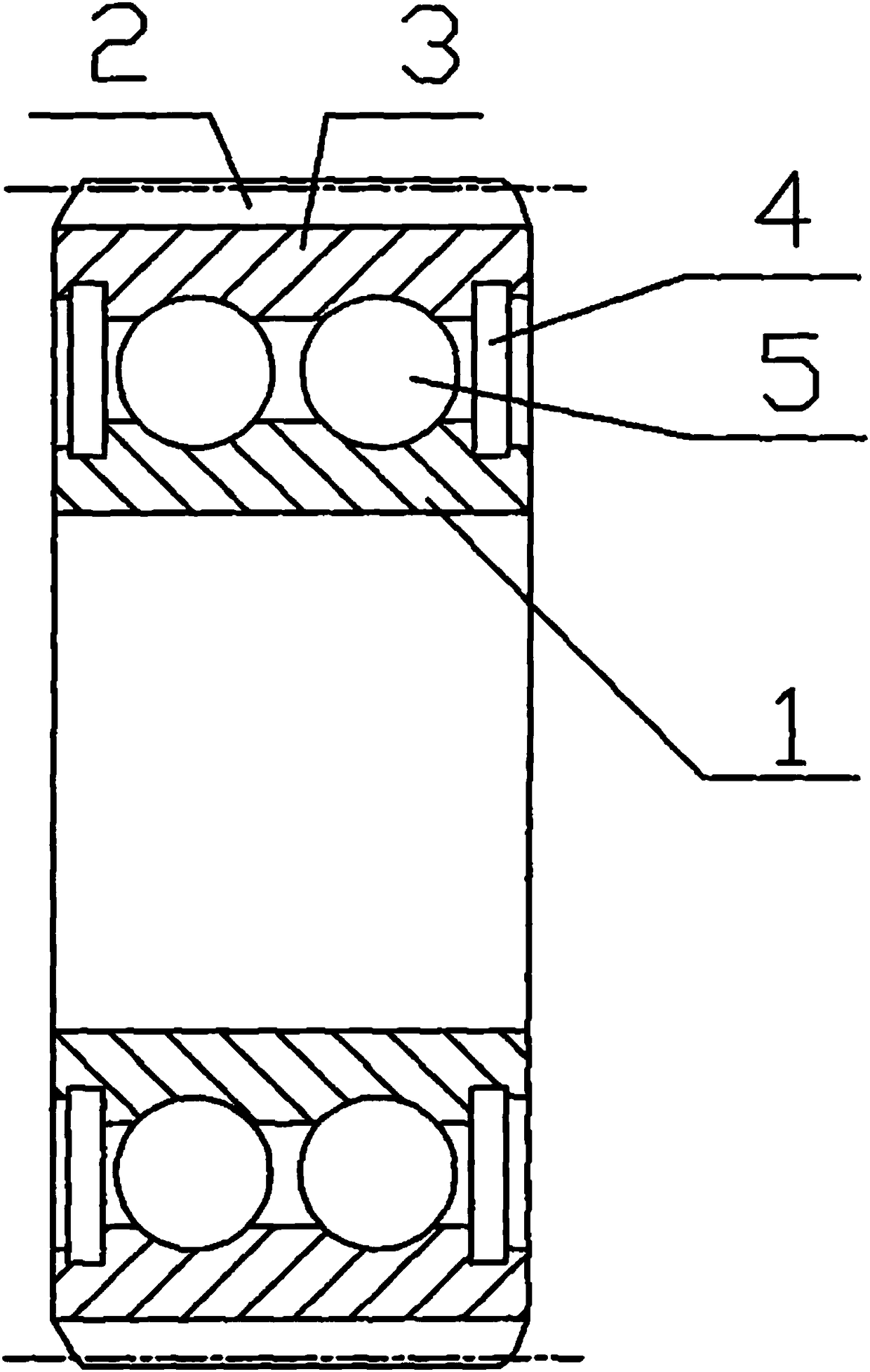

[0014] The following is attached figure 1 The structure of the present invention will be described in further detail.

[0015] A high load bearing gear bearing, comprising an outer bead rail 3, an inner bead rail 1 and a ceramic rolling element 5, the outer bead rail 3 and the inner bead rail 1 are arranged oppositely, and the ceramic rolling element 5 is positioned on the outer bead rail 3 and the raceway of the inner ball rail 1; two annular oil seals 4 are also included between the outer ball rail 3 and the inner ball rail 1, and the two annular oil seals 4 are respectively located in the plurality of ceramic rolling On both sides of the component 5; the present invention is provided with an annular oil seal 4, which can effectively seal the bearing and prevent dust from entering the raceway. The bearing operates with low noise and small friction, which can effectively improve the bearing failure caused by high-speed wear and greatly improve the service life of the bearing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com