Frame front end overhanging beam support

A technology of overhanging beams and frames, which is applied to vehicle parts, substructure, transportation and packaging, etc., can solve the problems of unreasonable structure and heavy weight, and achieve the effect of reasonable structure, light weight and easy casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

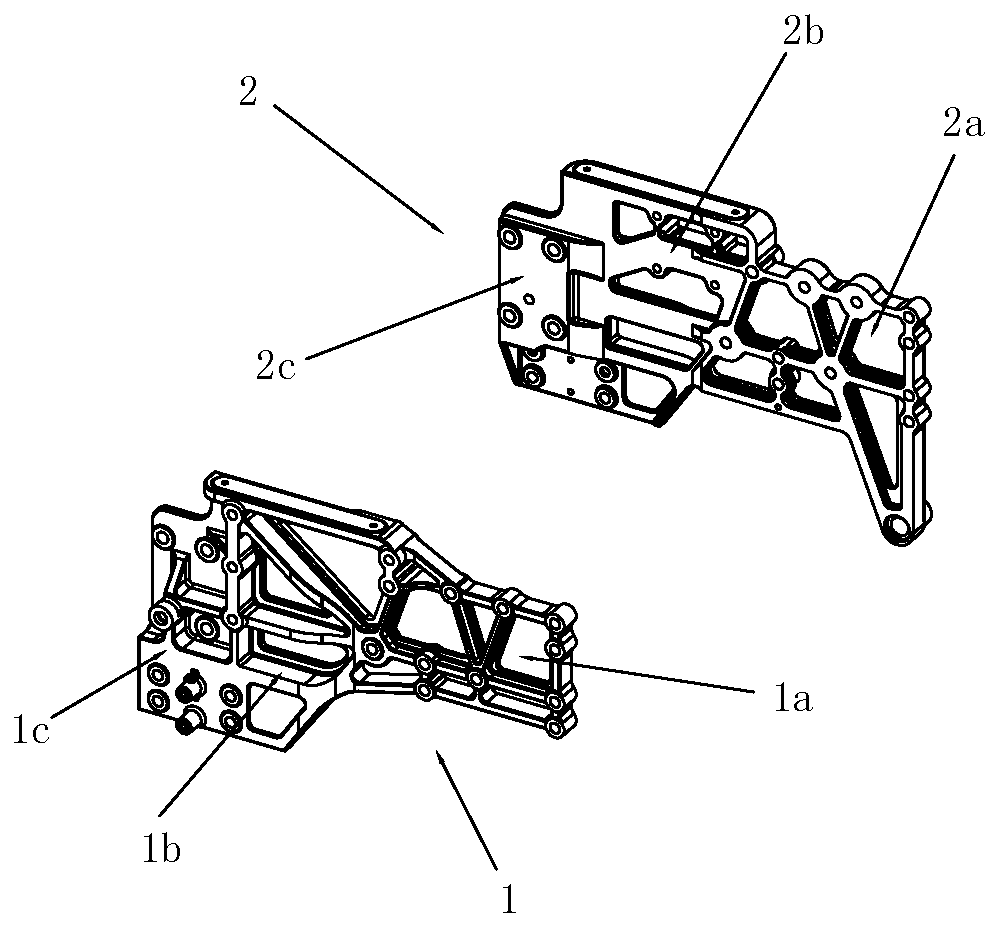

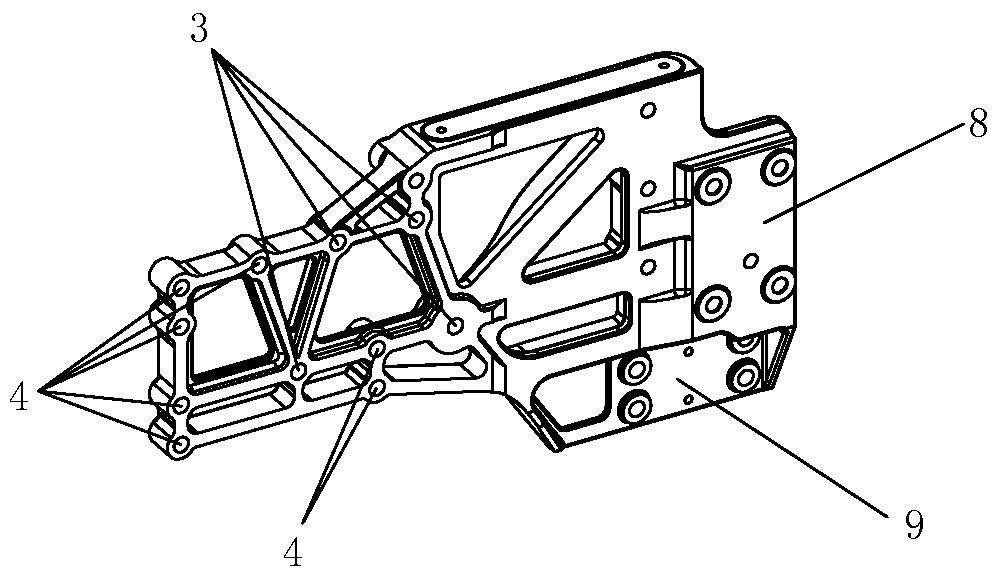

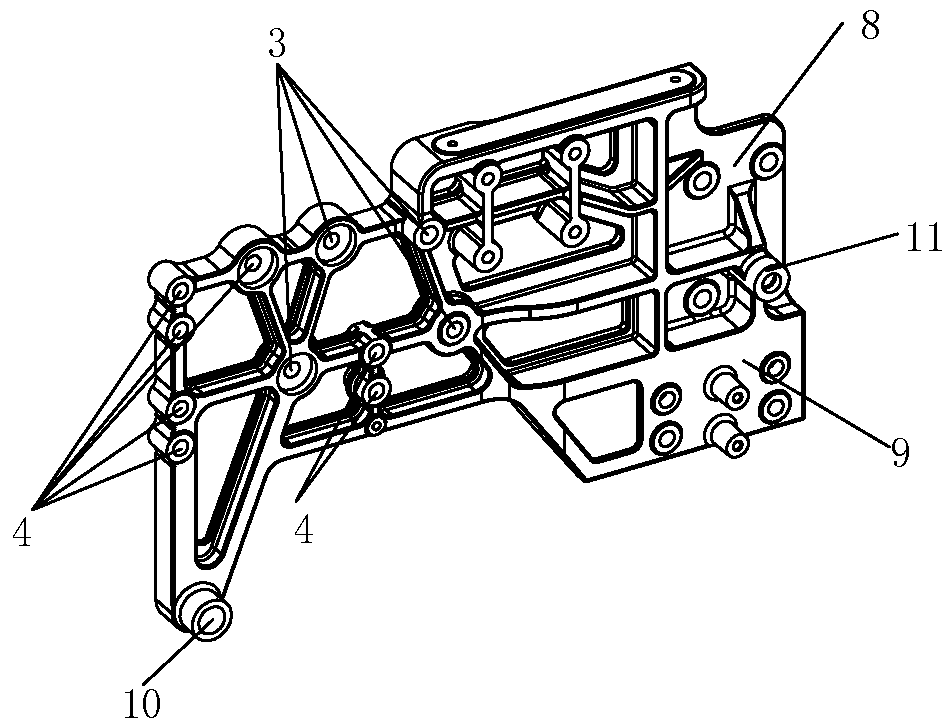

[0034] Such as Figure 1 to Figure 6 As shown, the outrigger bracket at the front end of the vehicle frame in this embodiment includes a left outrigger 1 and a right outrigger 2, and the left outrigger 1 and right outrigger 2 respectively include constrained areas 1a, 2a, Loaded areas 1b, 2b, assembly areas 1c, 2c; among them, the restraint areas 1a, 2a are used to connect with the left and right main girders respectively, and the assembly areas 1c, 2c are used to assemble beams (or bumpers), cooling systems, loaded The areas 1b, 2b are used to connect the confinement areas 1a, 2a and the assembly areas 1c, 2c, so that the assembly areas 1c, 2c can protrude out of the main girder. Among the three areas, the confinement area 1a, 2a and the loading area 1b, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com