Pre-tightening connecting assembly used for mounting curtain wallboard

A technology for connecting components and curtain wall panels, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of increasing the risk of high-altitude operations, inconvenient installation of curtain wall panels, and affecting the thermal insulation performance of curtain walls, so as to achieve firm and reliable connections and improve Convenience and the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

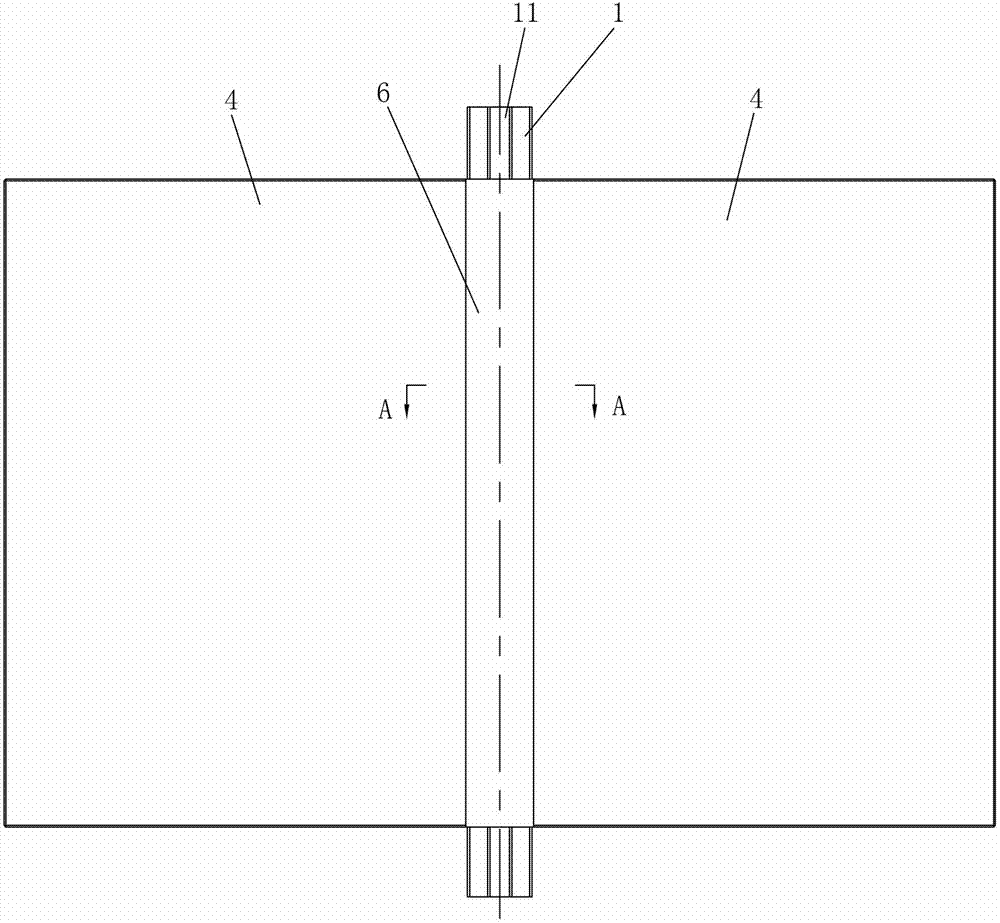

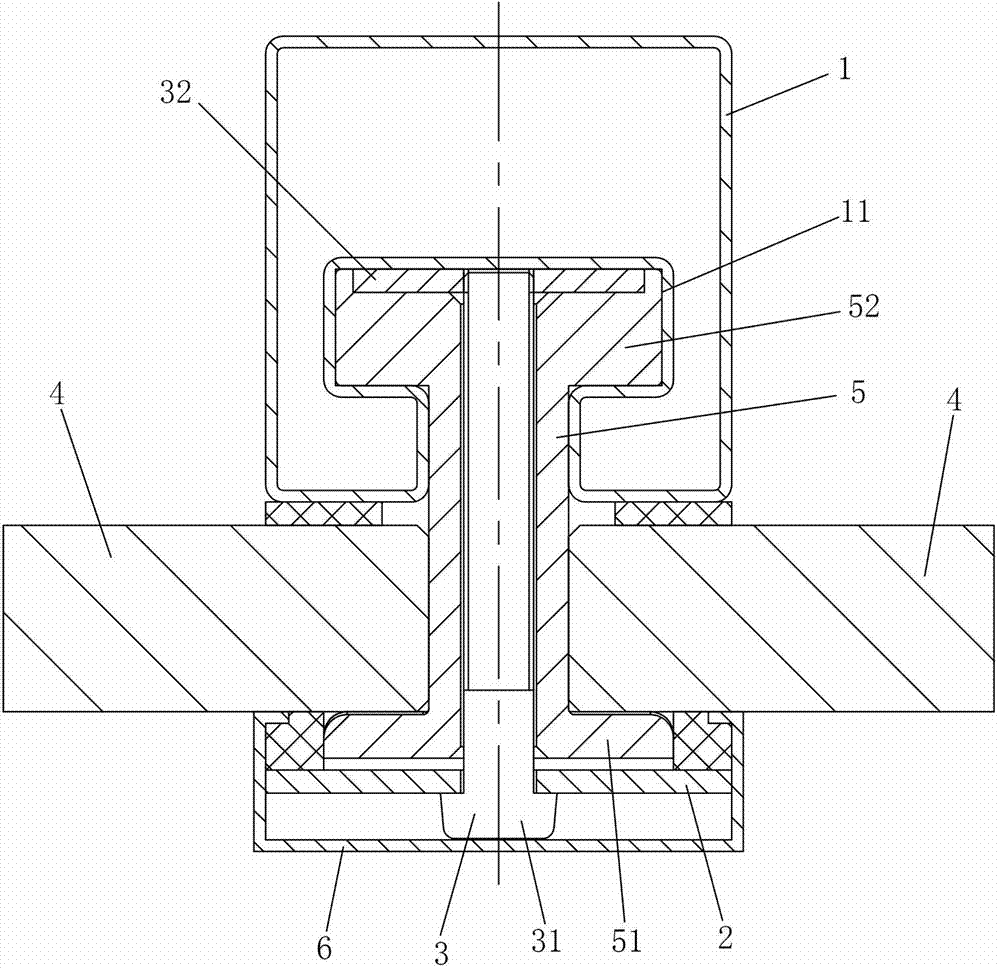

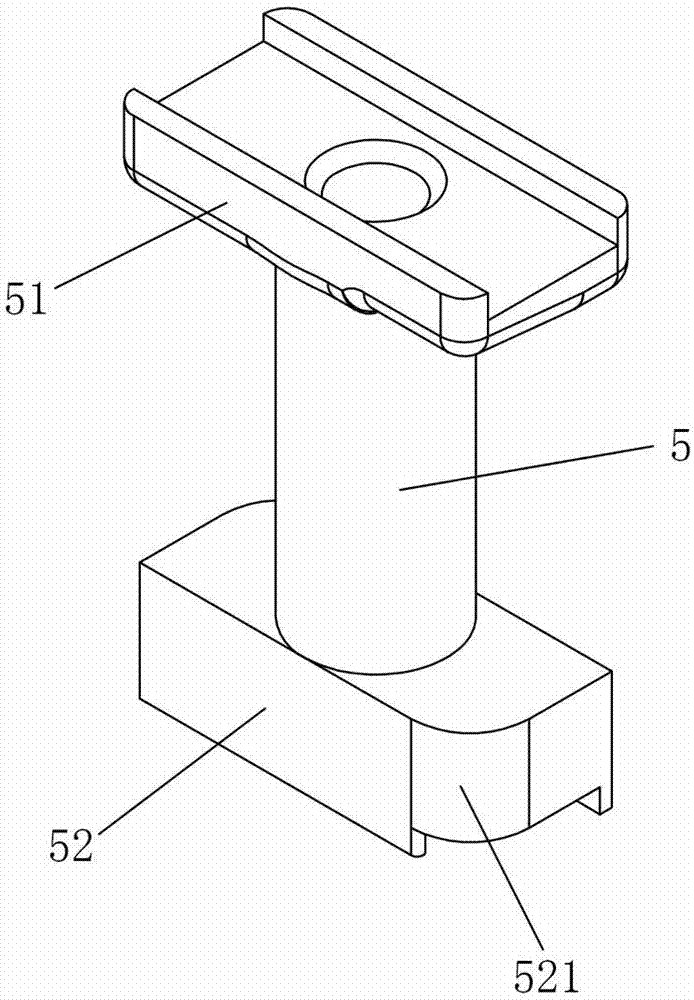

[0026] Figure 1 to Figure 3 It shows the first embodiment of the pre-tightening connection assembly used in the installation of curtain wall panels of the present invention, including the keel 1 for supporting the curtain wall panel 4, and the limiting part 5 made of heat insulating material, the limiting part 5 It is detachably connected with the keel 1 , and the limiting part 5 is provided with a limiting part 51 , and a limiting groove for pre-tightening and positioning the curtain wall panel 4 is formed between the limiting part 51 and the keel 1 . When installing the curtain wall using the pre-tightened connection assembly for curtain wall panel installation of the present invention, after the curtain wall panel 4 is placed on the pre-installed position of the keel 1, the curtain wall panel 4 can be pre-tightened and positioned by using the limiting part 5, and then pressed and fixed The pressing and fixing work of curtain wall panel 4 can be carried out at any time afte...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, the difference is that the second connecting portion 53 of the limiting member 5 in this embodiment is in the shape of a truncated cone, and the structure of the limiting member 5 is as follows Figure 4 As shown, it is connected to the keel 1 through the second connecting portion 53 in the shape of a truncated cone. The second connecting portion 53 in the shape of a truncated cone is snapped into the engaging groove 11 and can slide along the engaging groove 11 to adjust the installation position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com